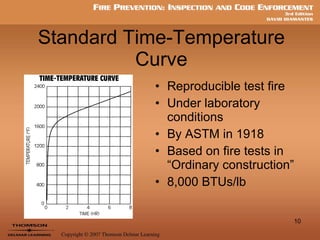

This document discusses fire-resistive construction elements and ratings. It describes the difference between specification codes, which specify construction types, and performance codes, which identify required fire resistance in hours. Rated assemblies are tested according to standard time-temperature curves to determine their ability to support loads, limit heat transfer, and prevent fire spread for a specified time period. Openings in rated walls and barriers must be protected, and fire blocking and draft stopping are used to control fire spread in concealed spaces.