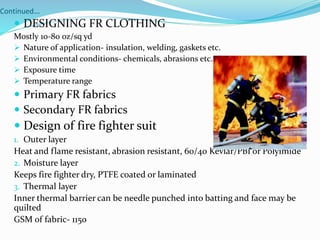

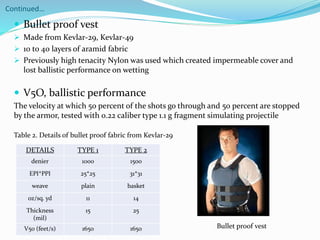

This document discusses safety and protective textiles. It covers various types of protection textiles provide, including protection from extreme heat/fire, hazardous chemicals/gases, mechanical injury, electromagnetic radiation, and ballistic threats. Different fiber materials and their properties are described for each protection application. Design considerations for protective clothing for firefighting, chemical handling, and ballistic vests are also outlined. The market for protective textiles in India is growing at around 11-12% annually due to increasing worker safety standards and defense sector demands. Continuous innovation is needed to meet evolving protection needs and performance requirements.