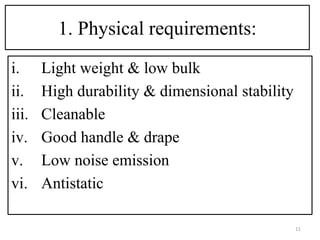

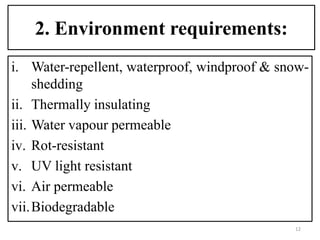

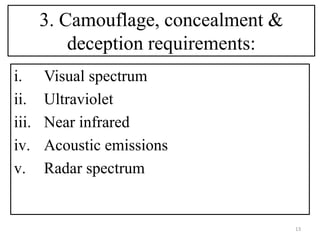

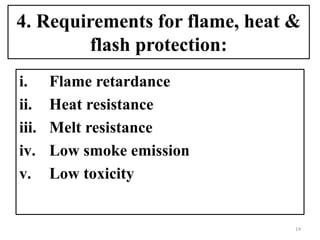

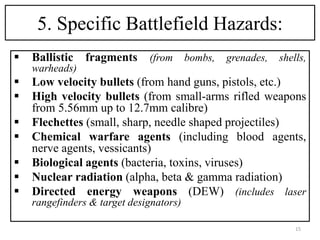

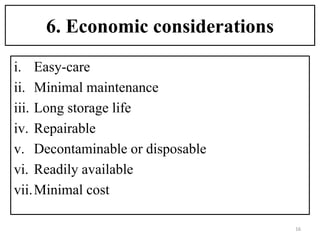

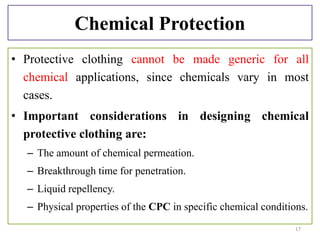

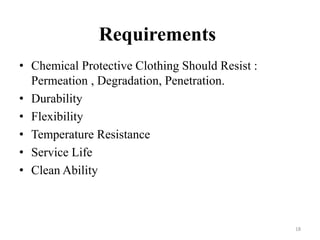

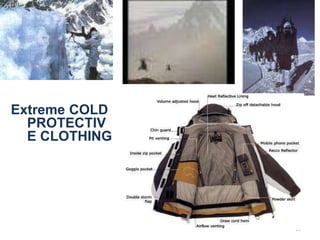

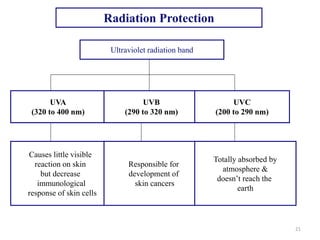

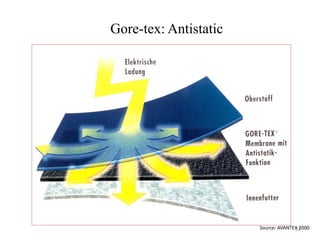

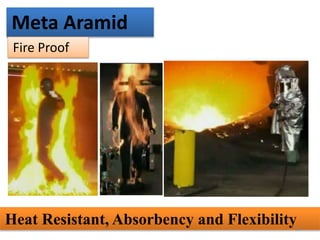

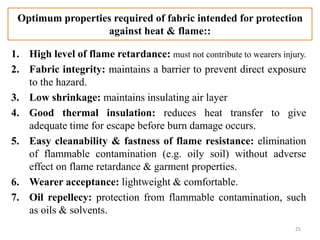

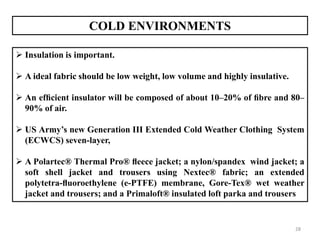

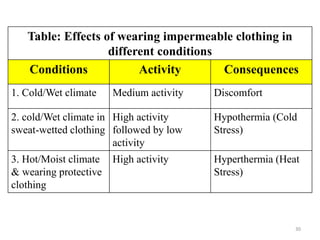

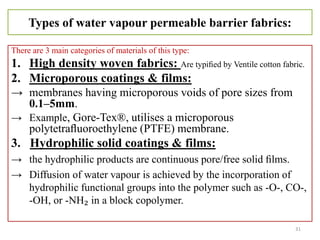

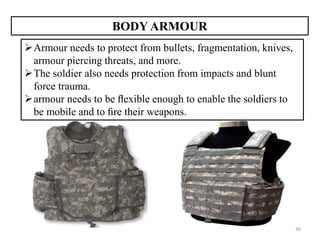

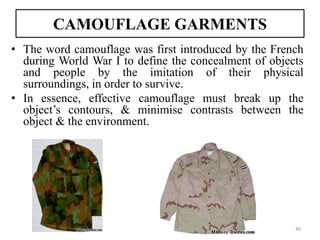

This presentation discusses protective textiles and their uses in various applications such as protective clothing. Protective textiles are made from specialty fibers that provide protection against heat, radiation, molten metals, bullets, and chemicals. They are often used to manufacture personal protective equipment for applications like firefighting clothing, welding protection, bulletproof vests, and chemical protective gear. The presentation discusses the criteria for different types of protective textiles and clothing used in military and industrial settings to provide insulation, waterproofing, flame resistance, ballistic protection, and protection against biological and chemical threats.