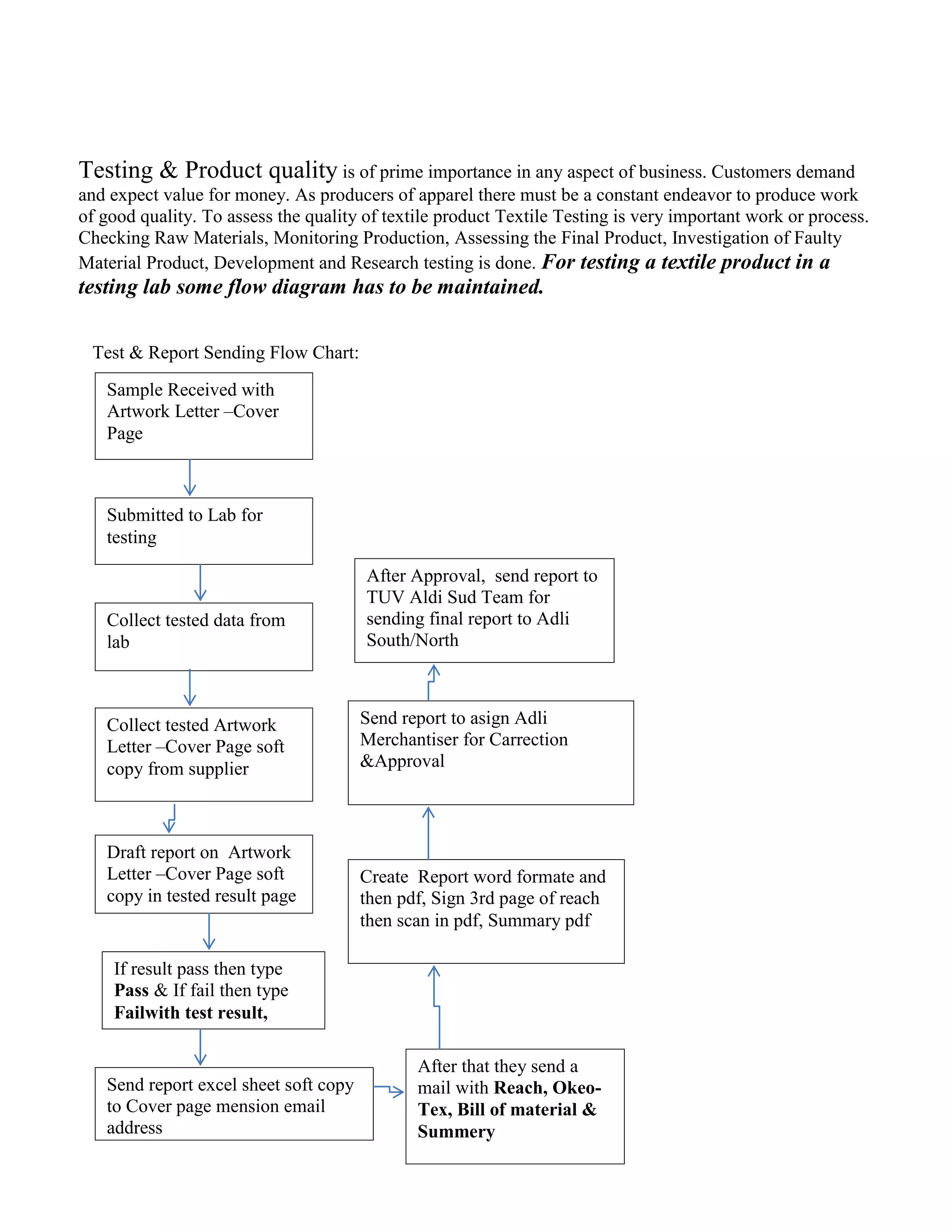

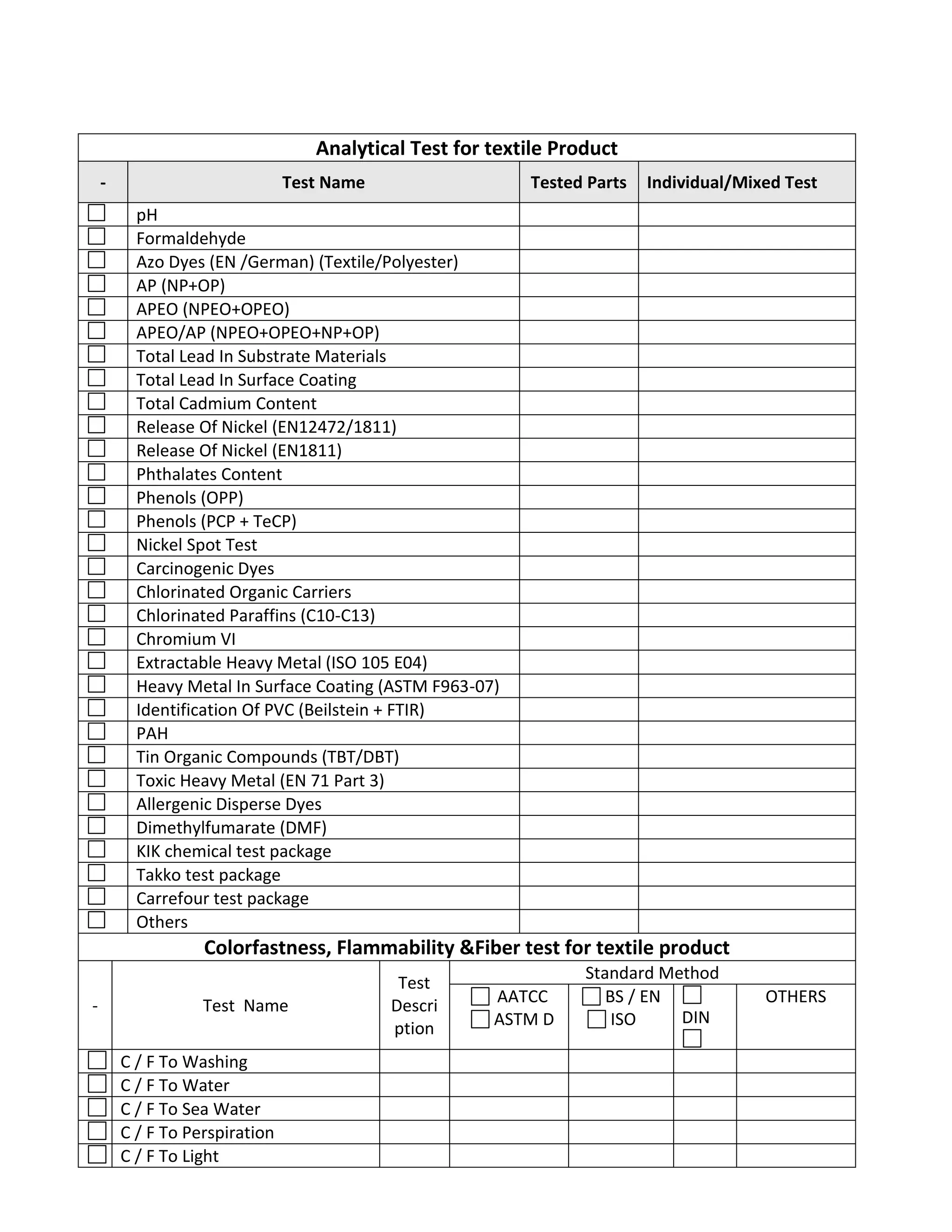

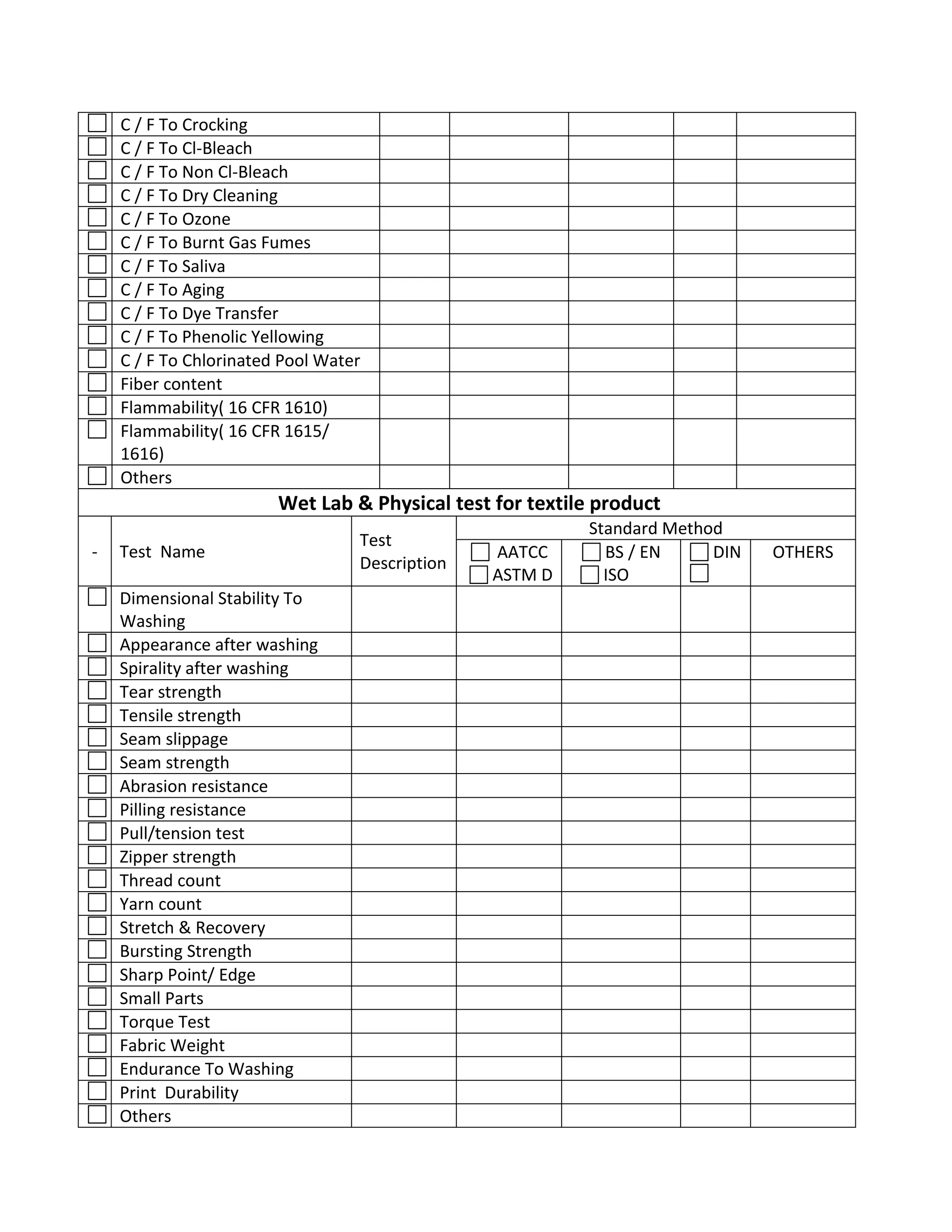

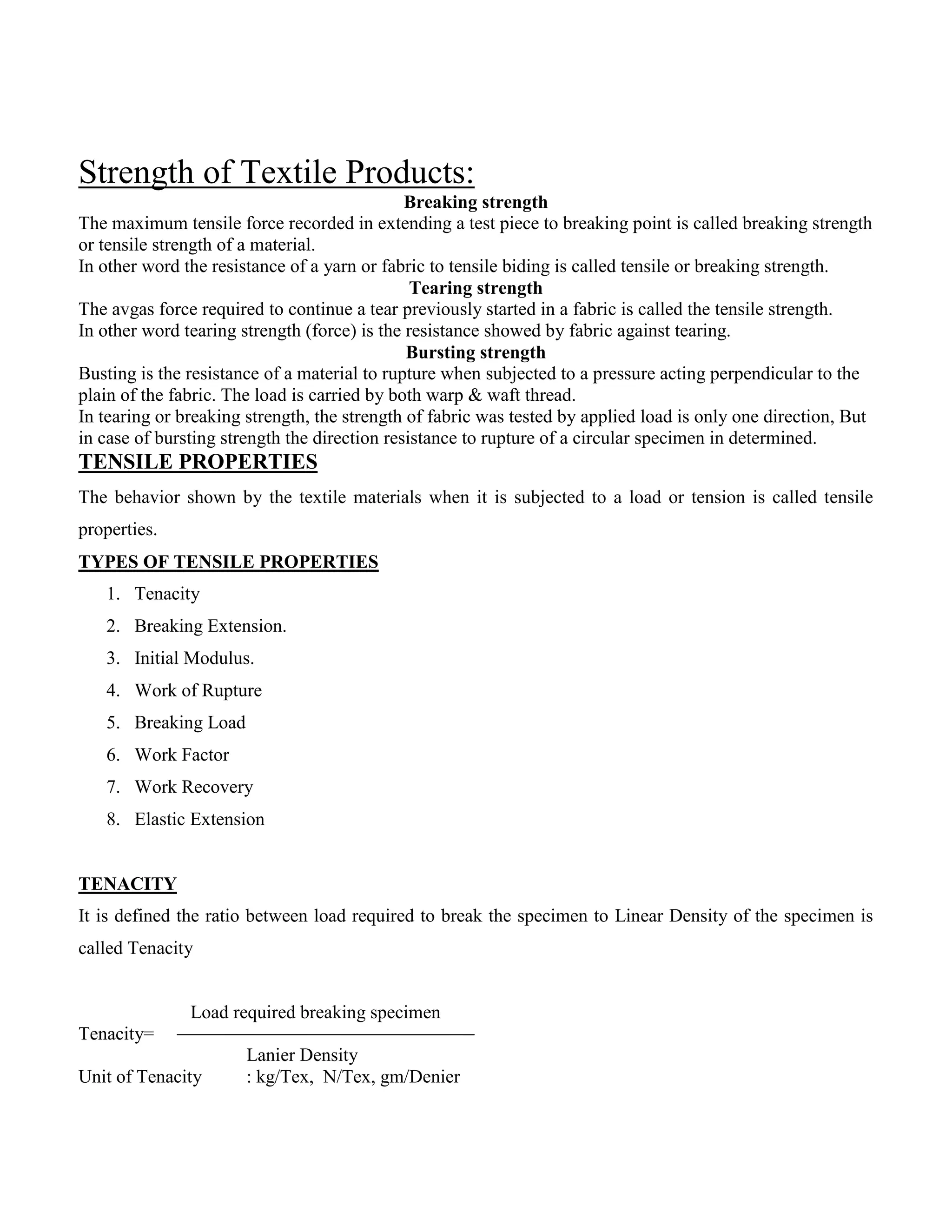

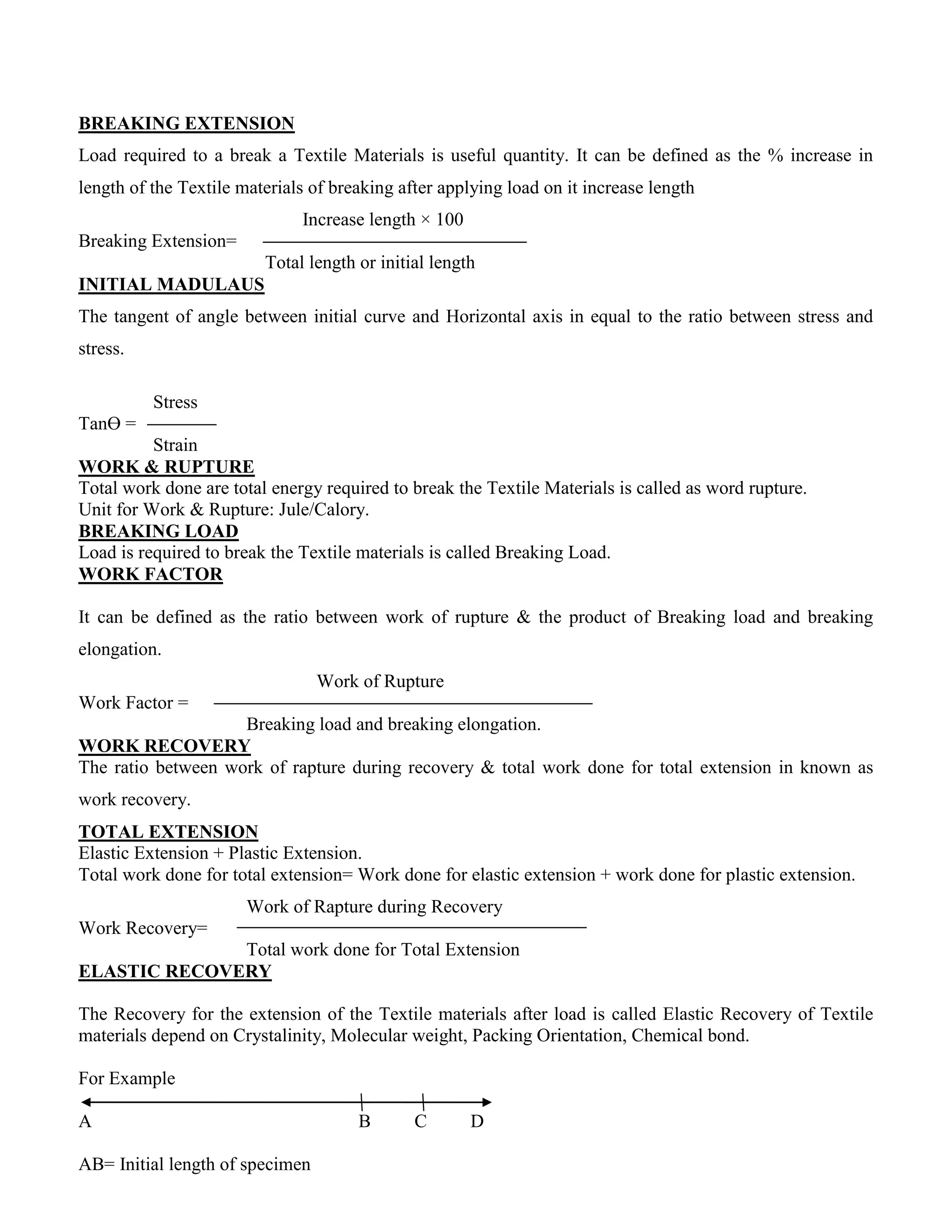

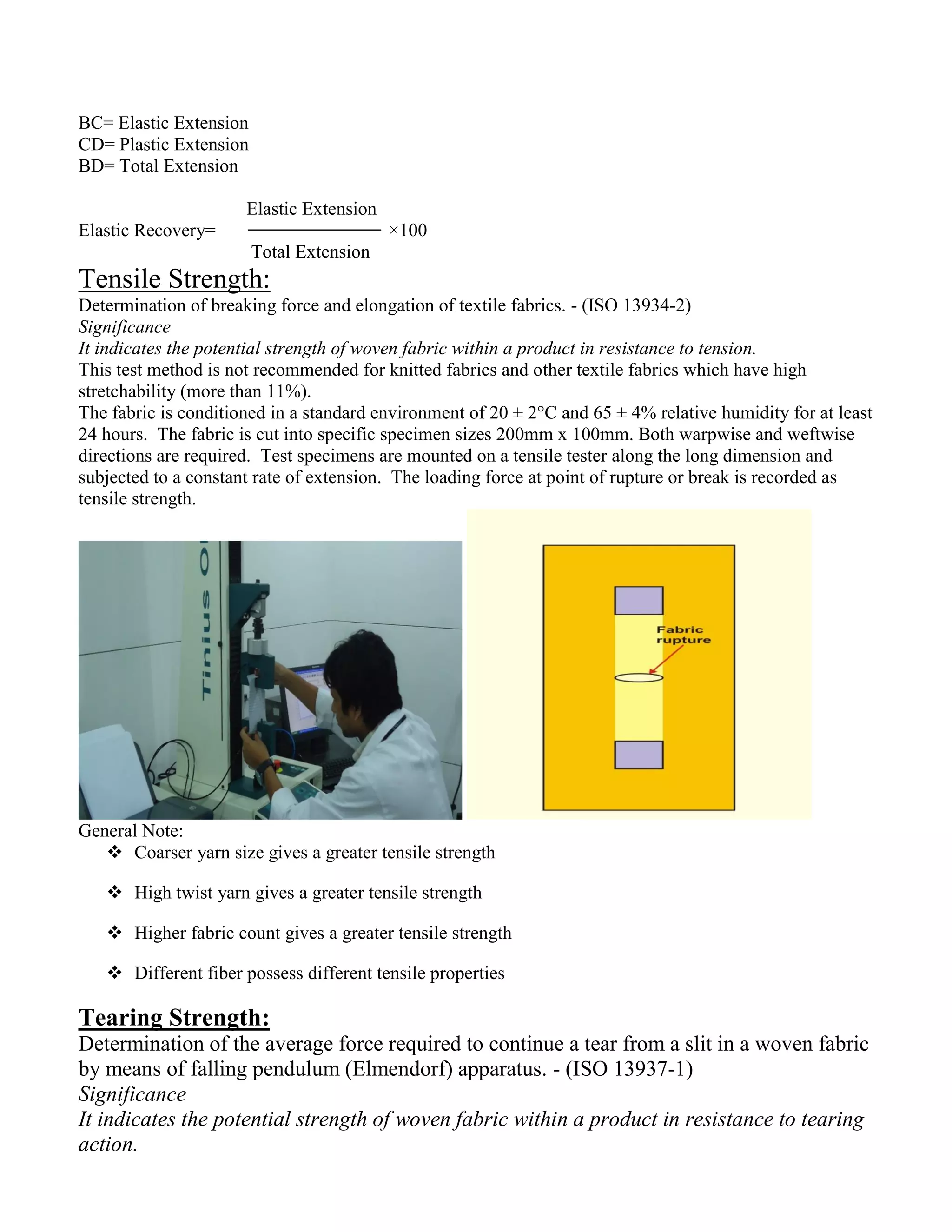

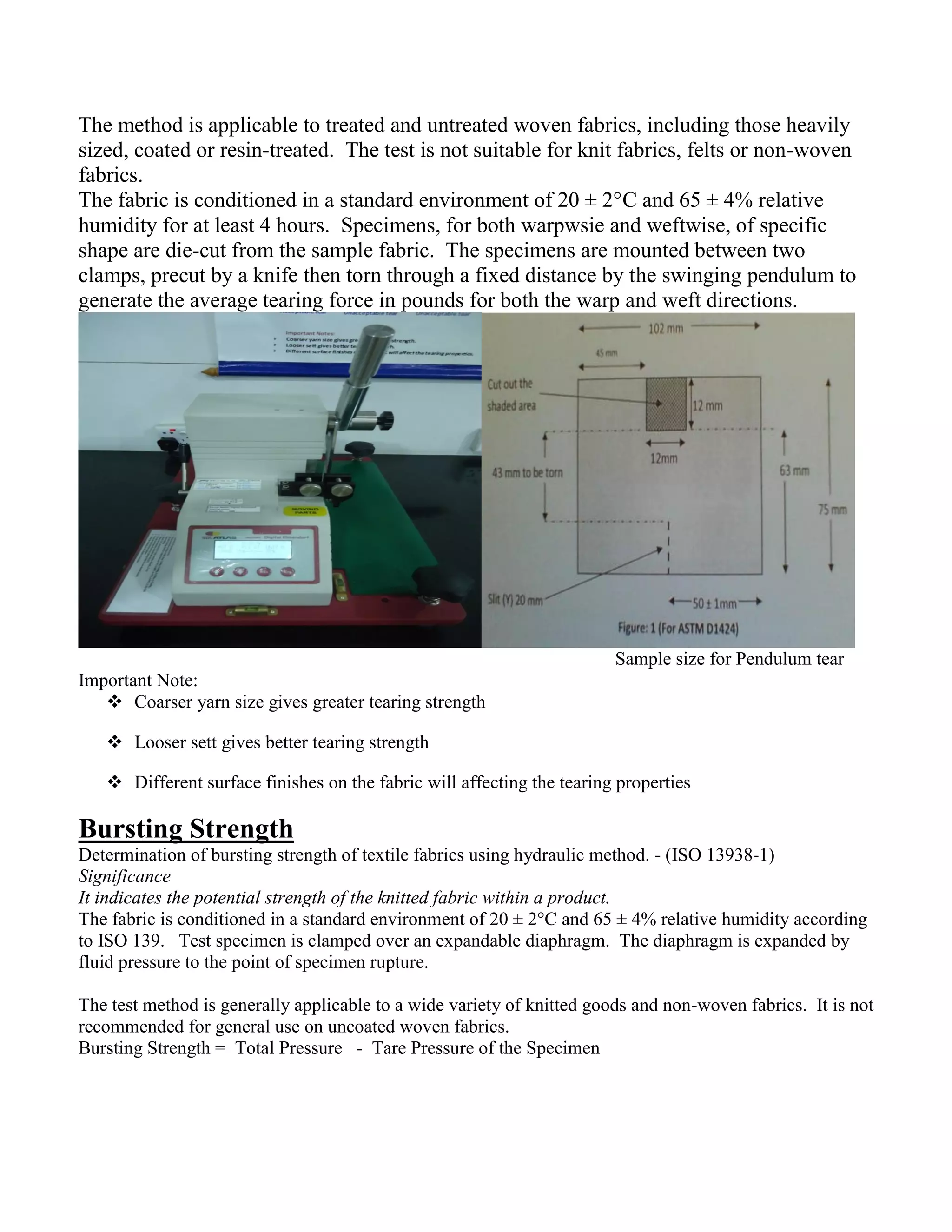

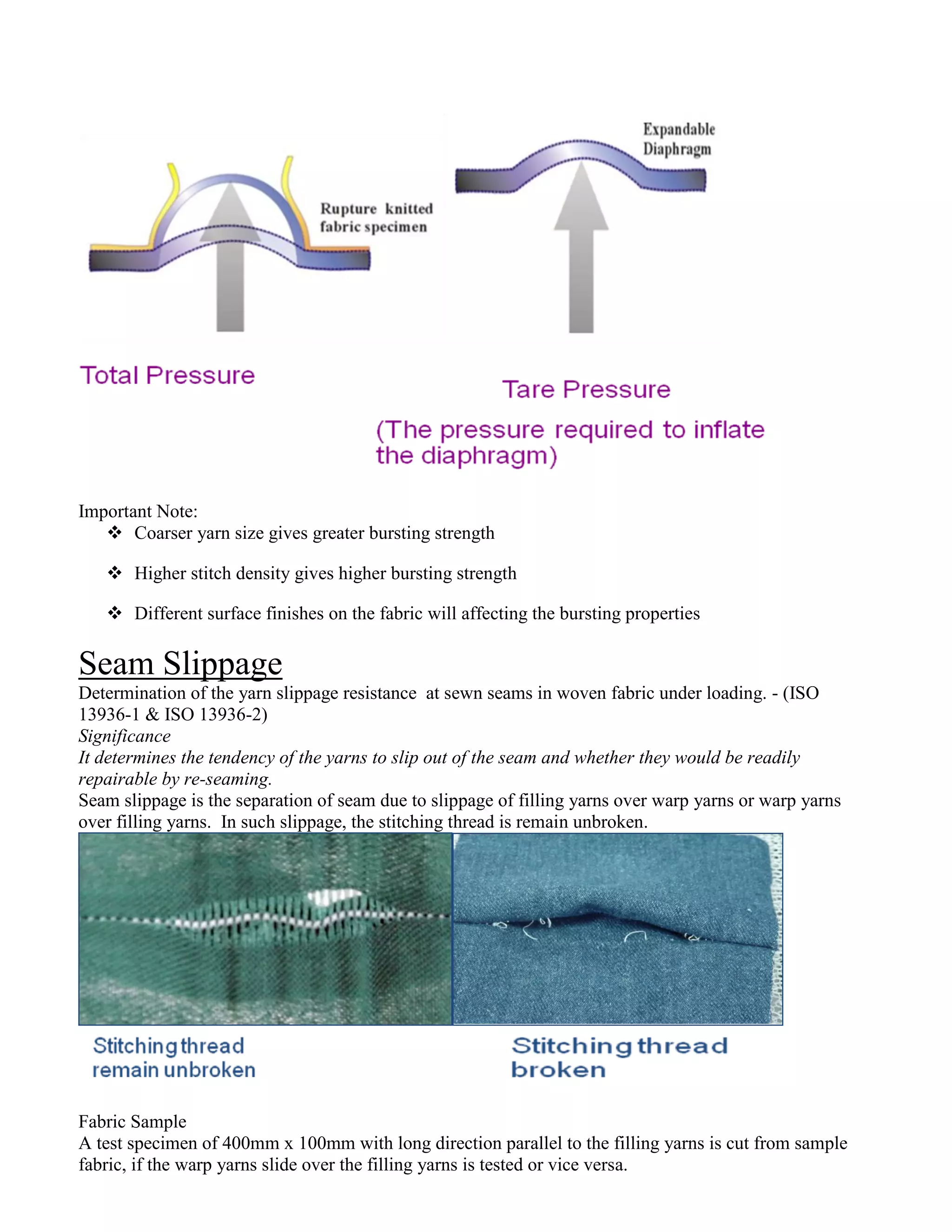

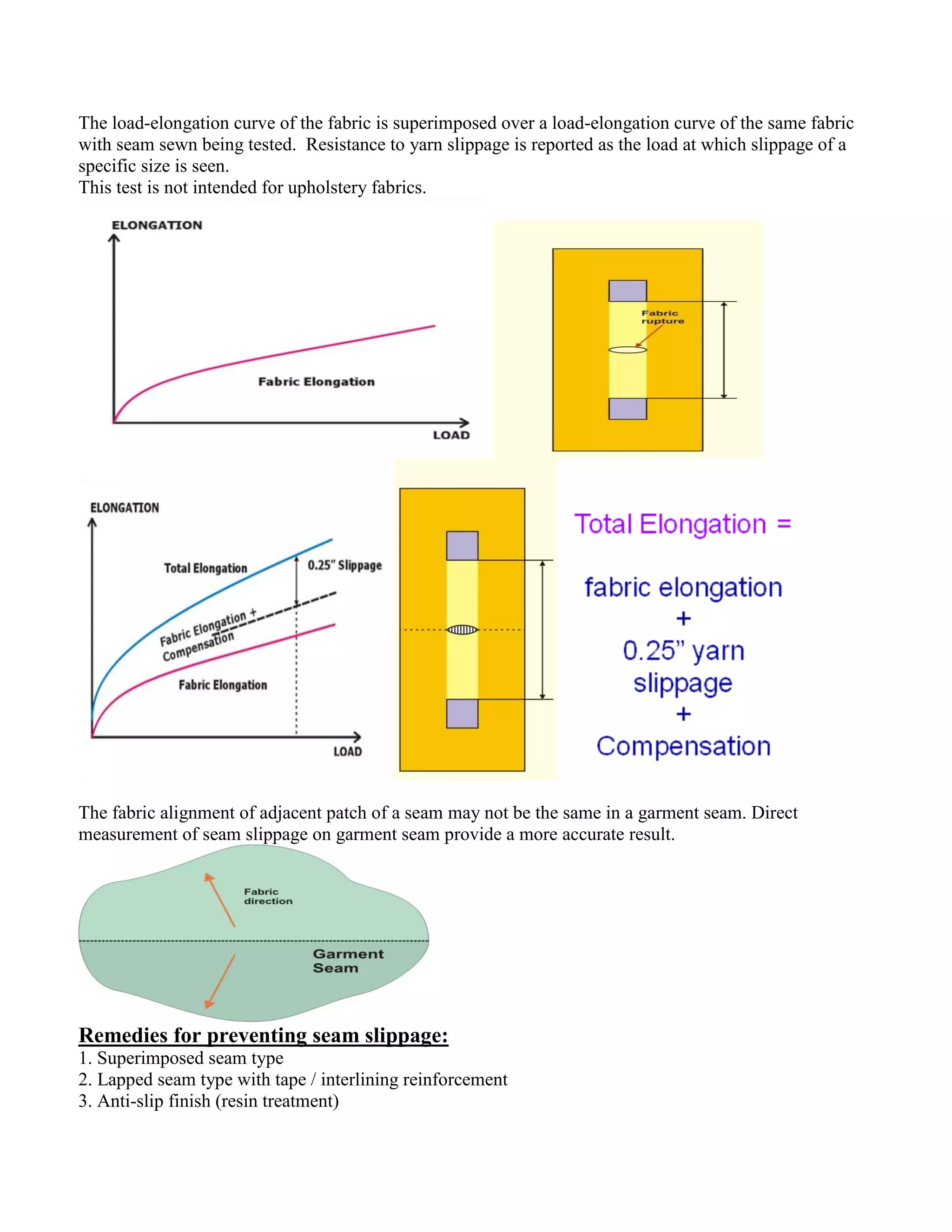

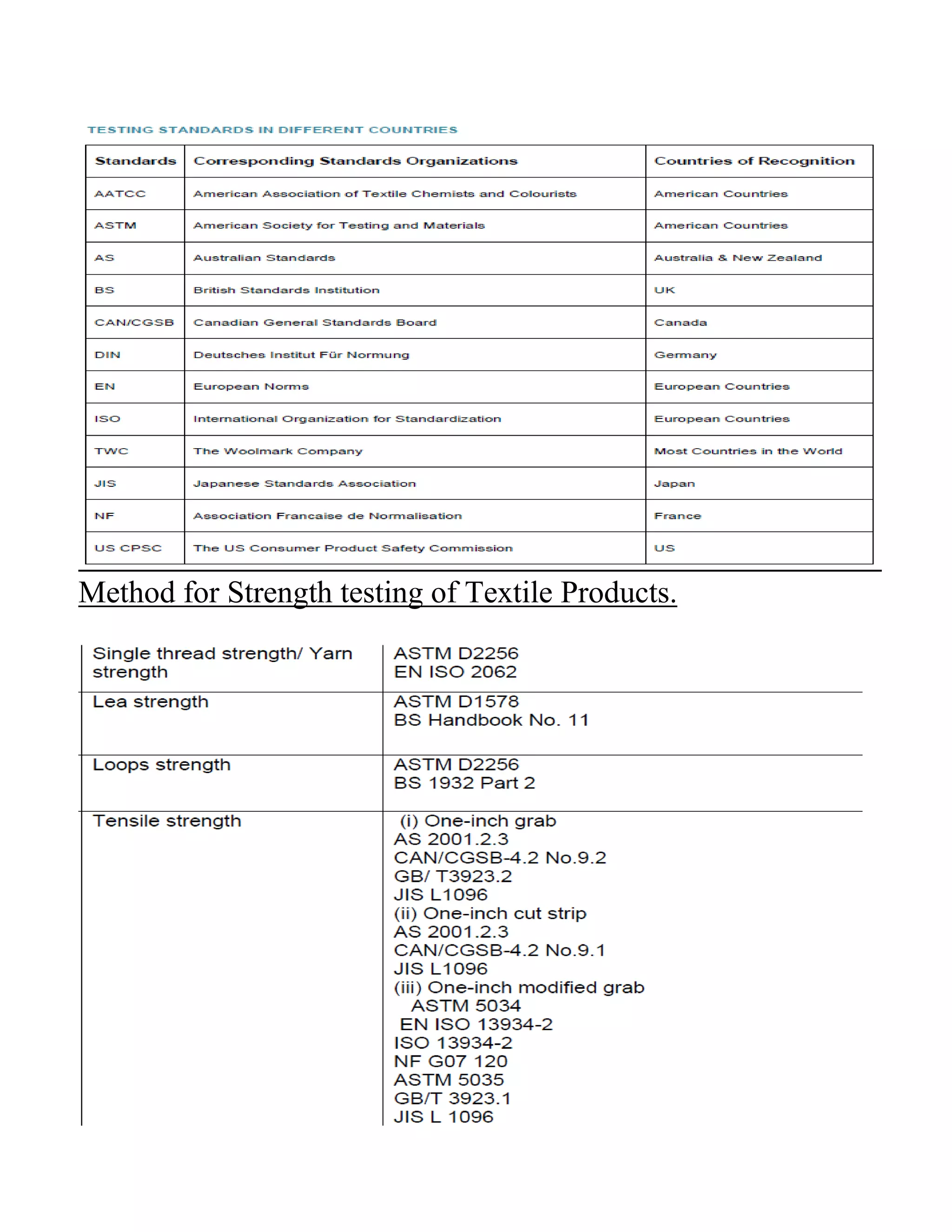

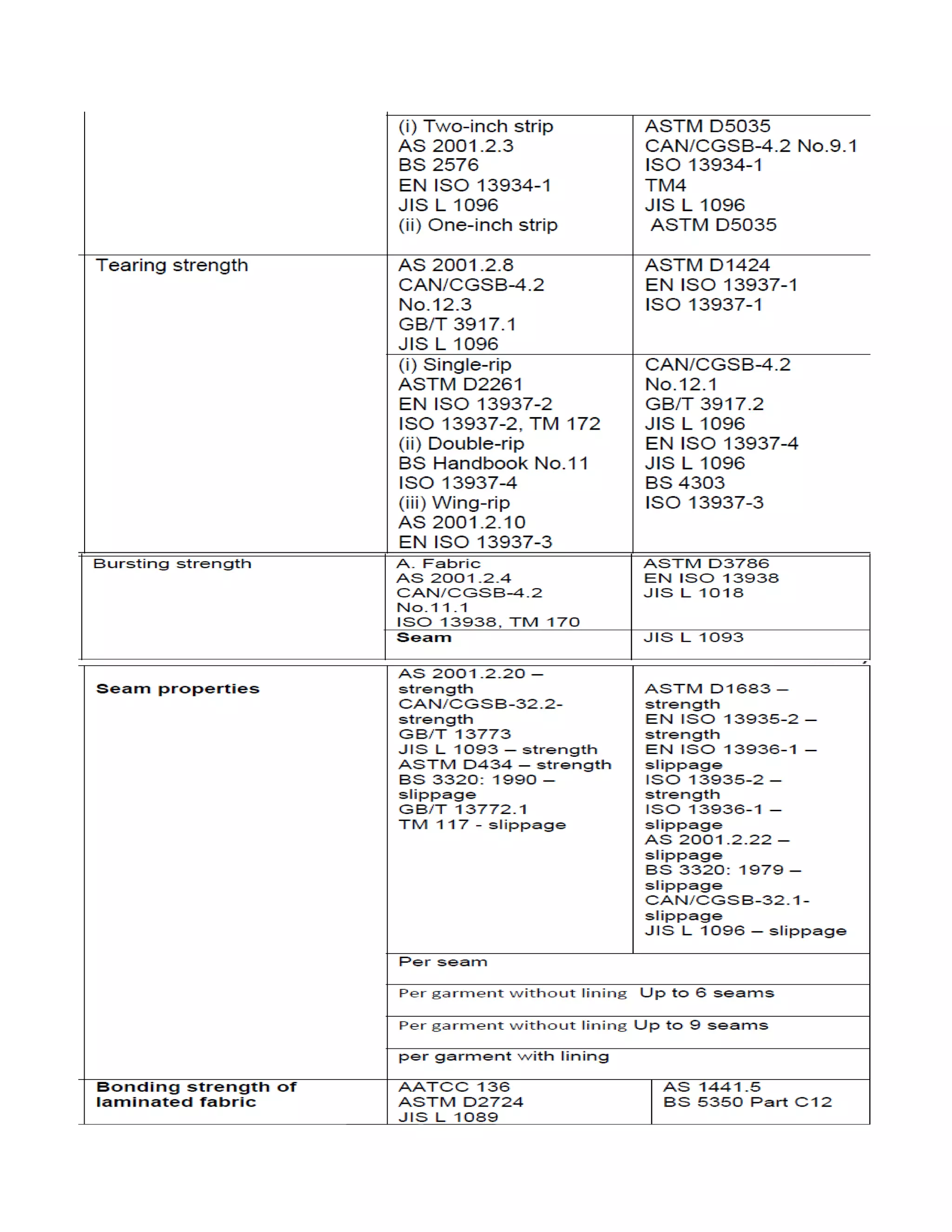

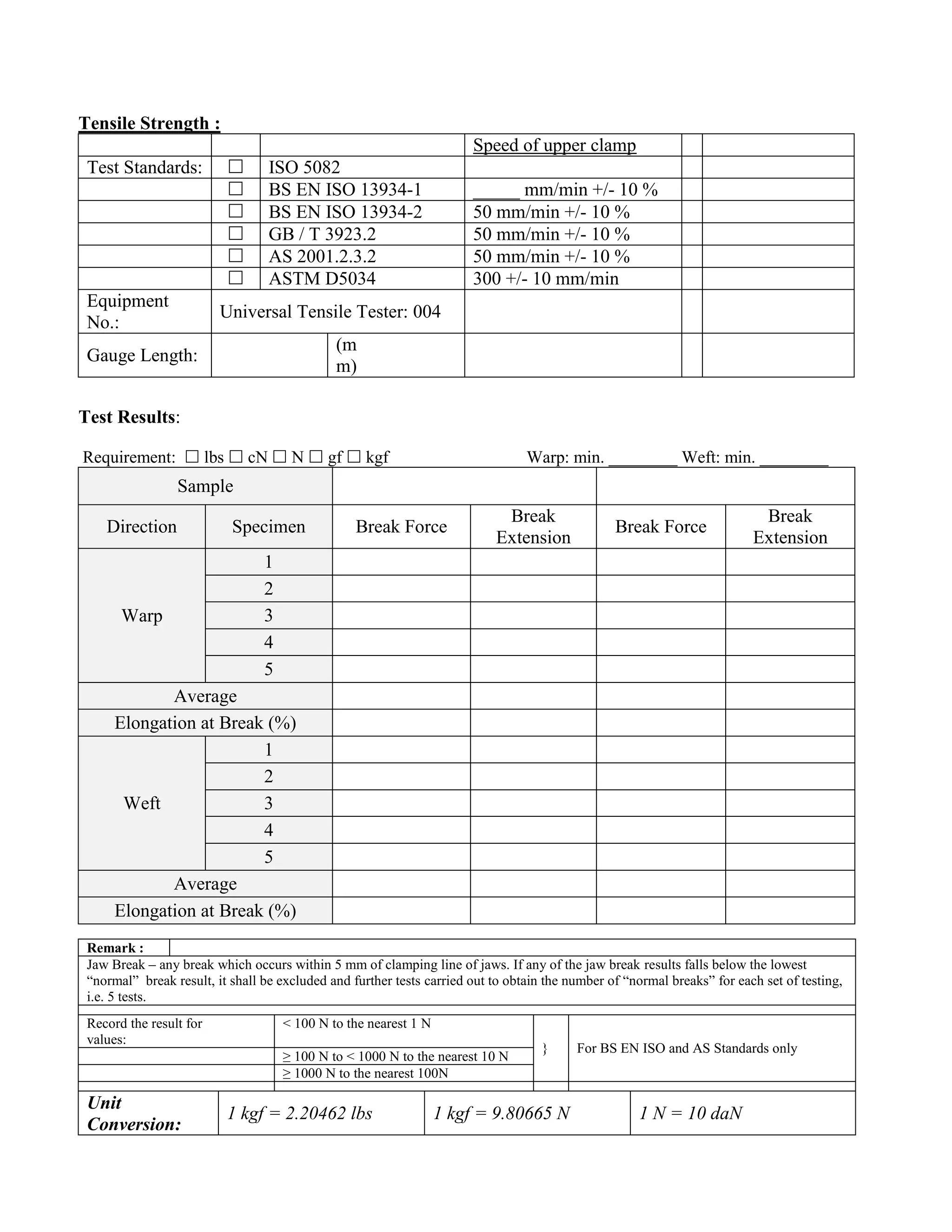

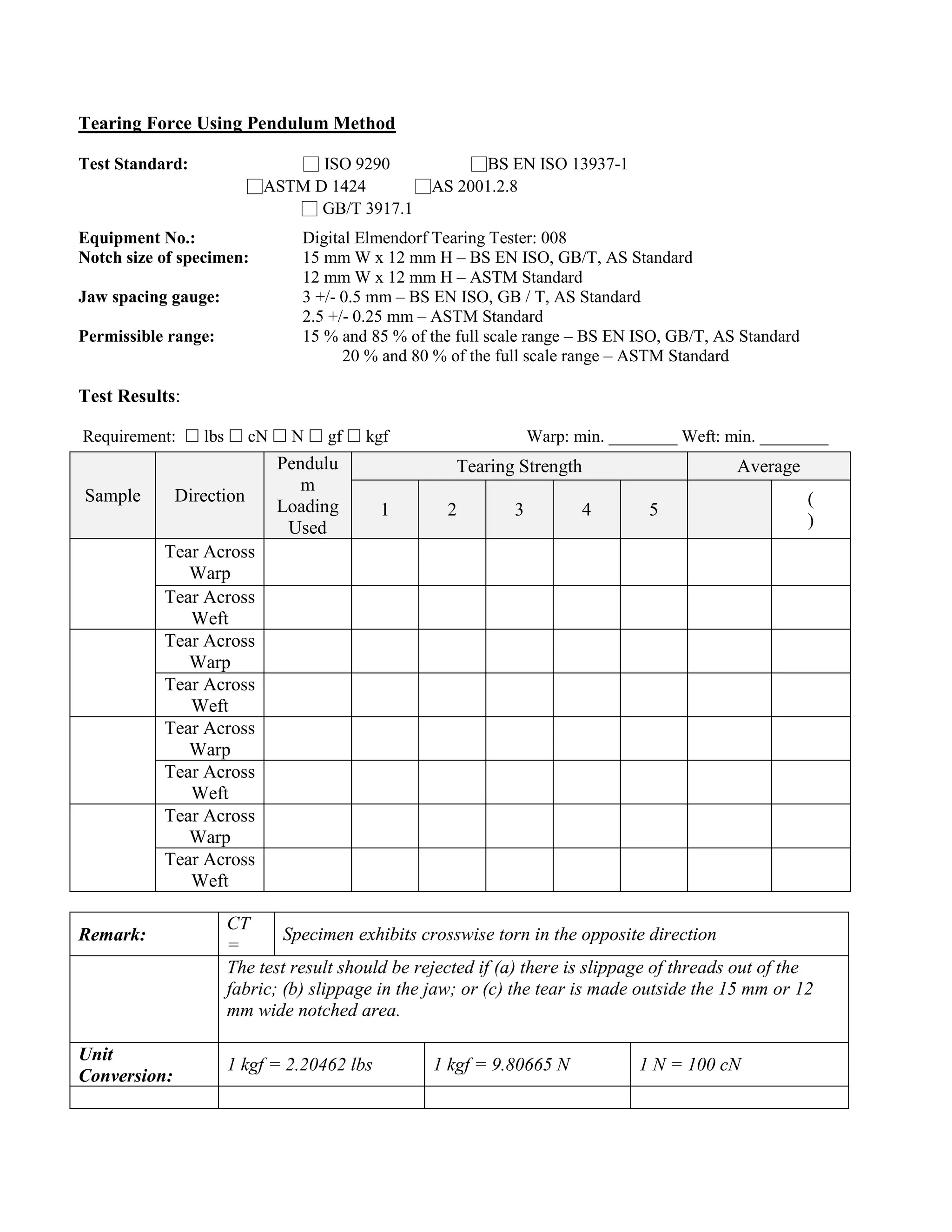

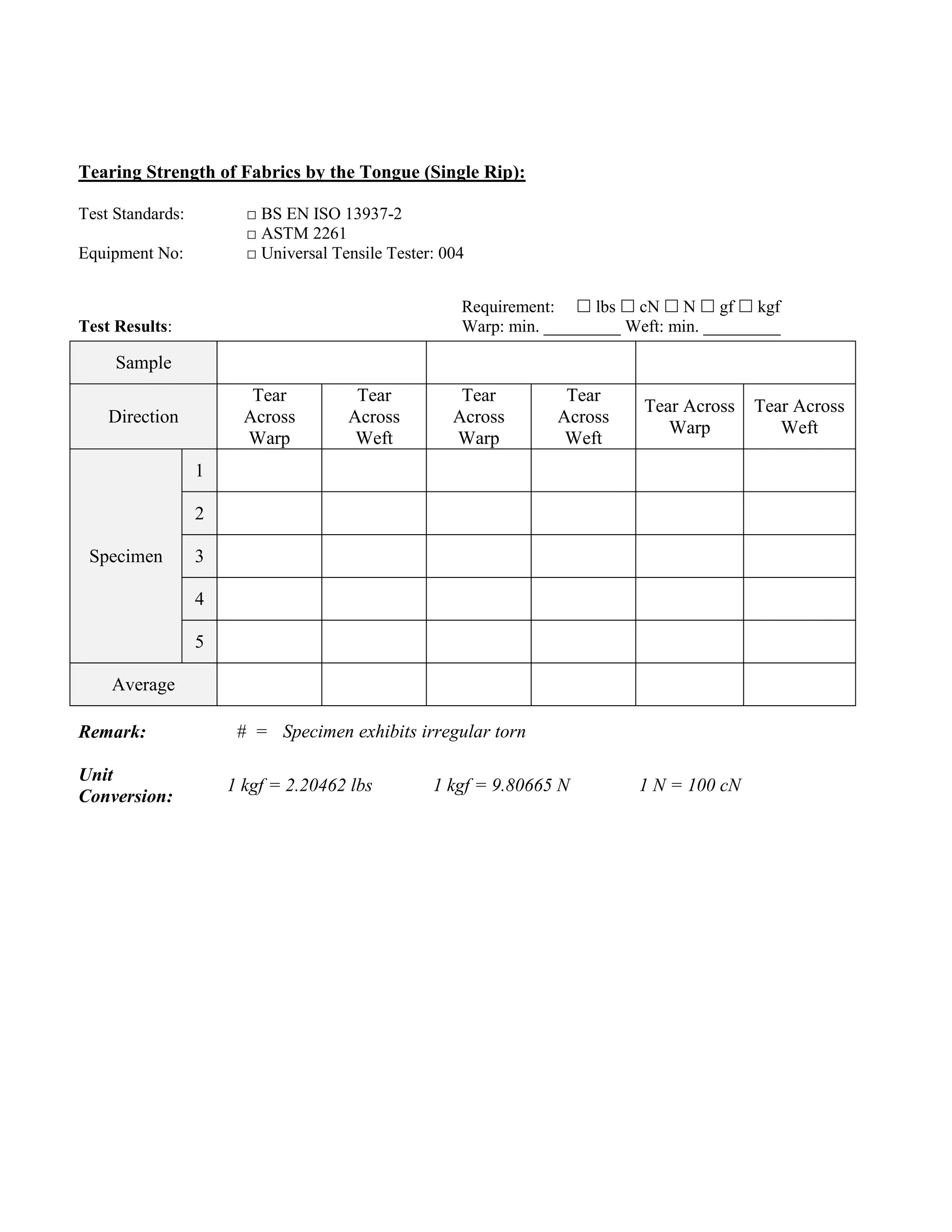

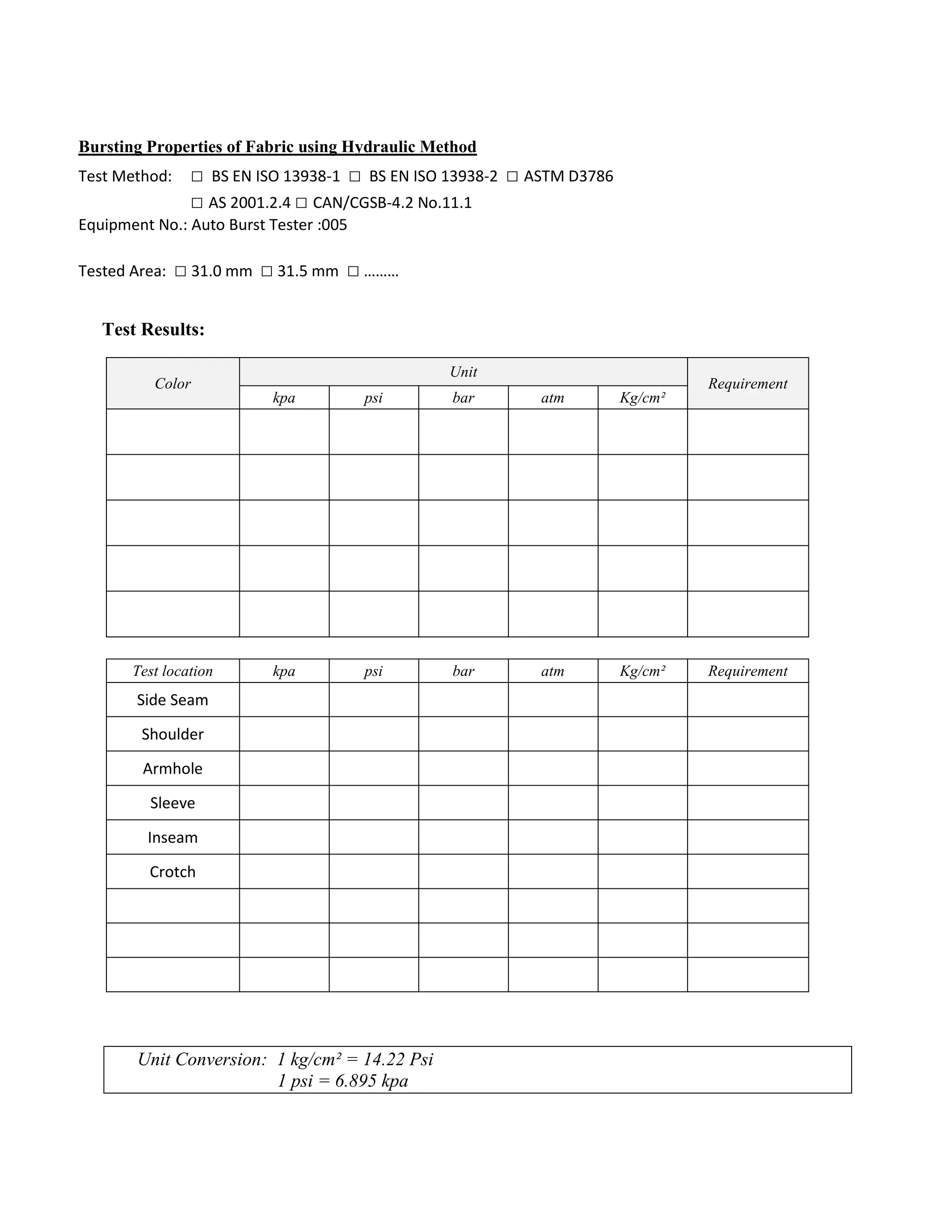

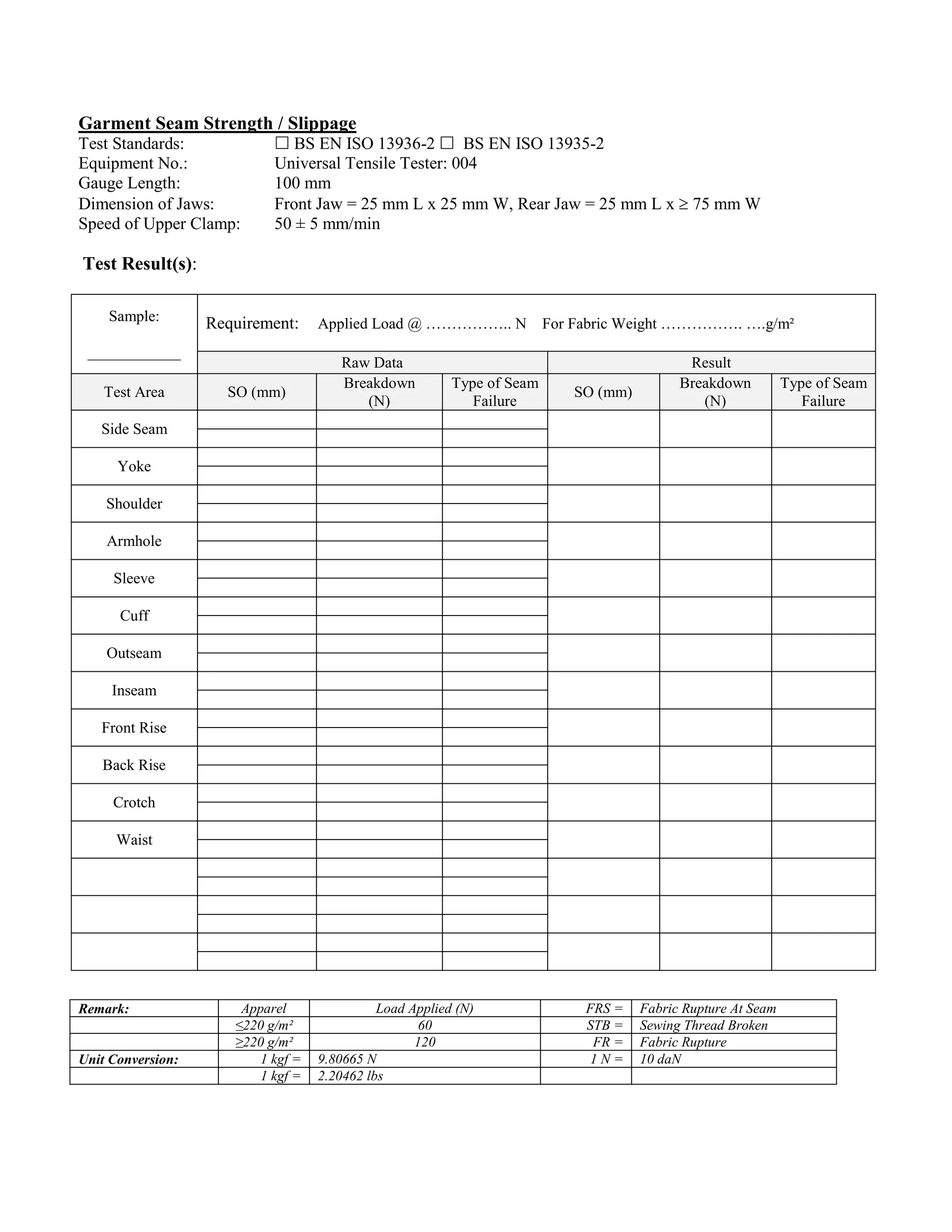

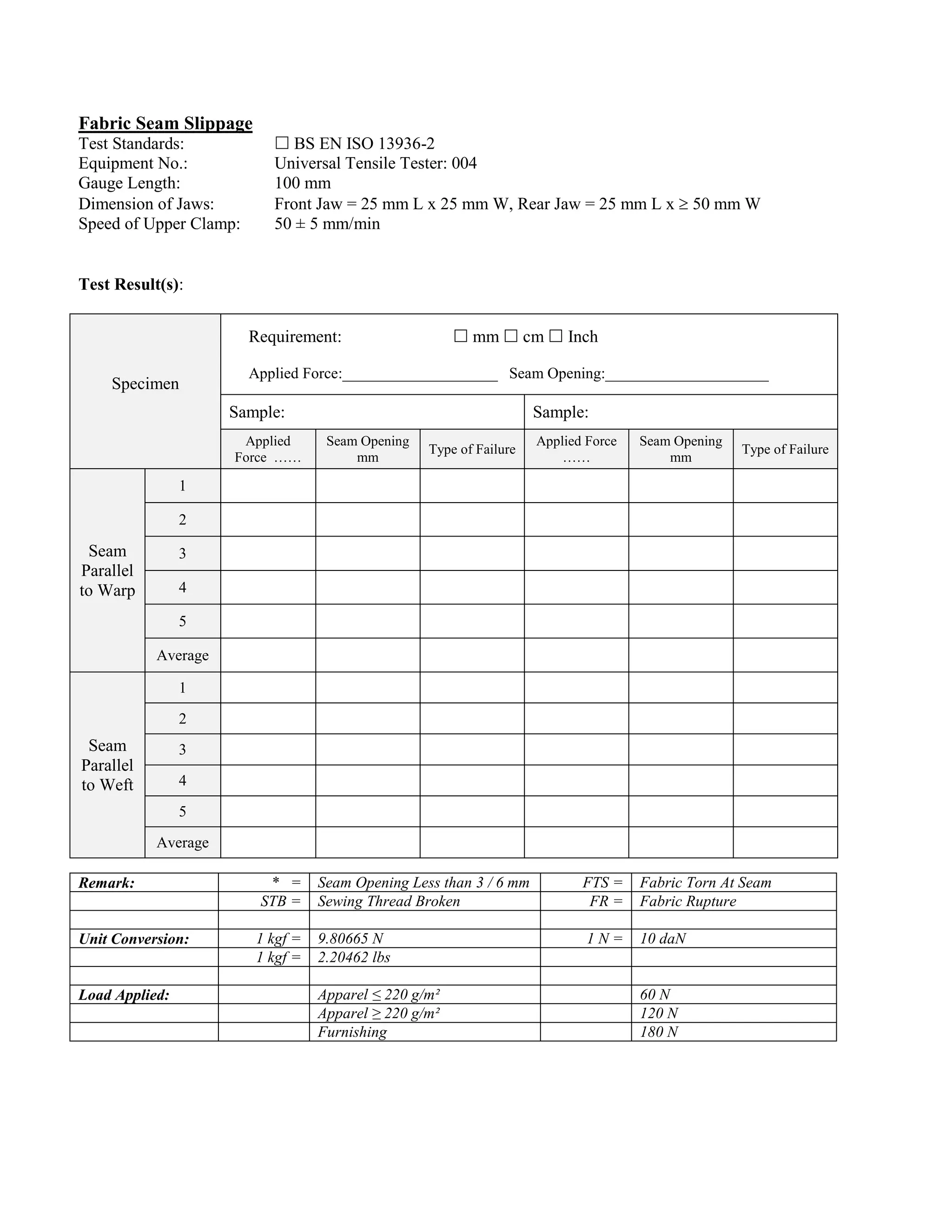

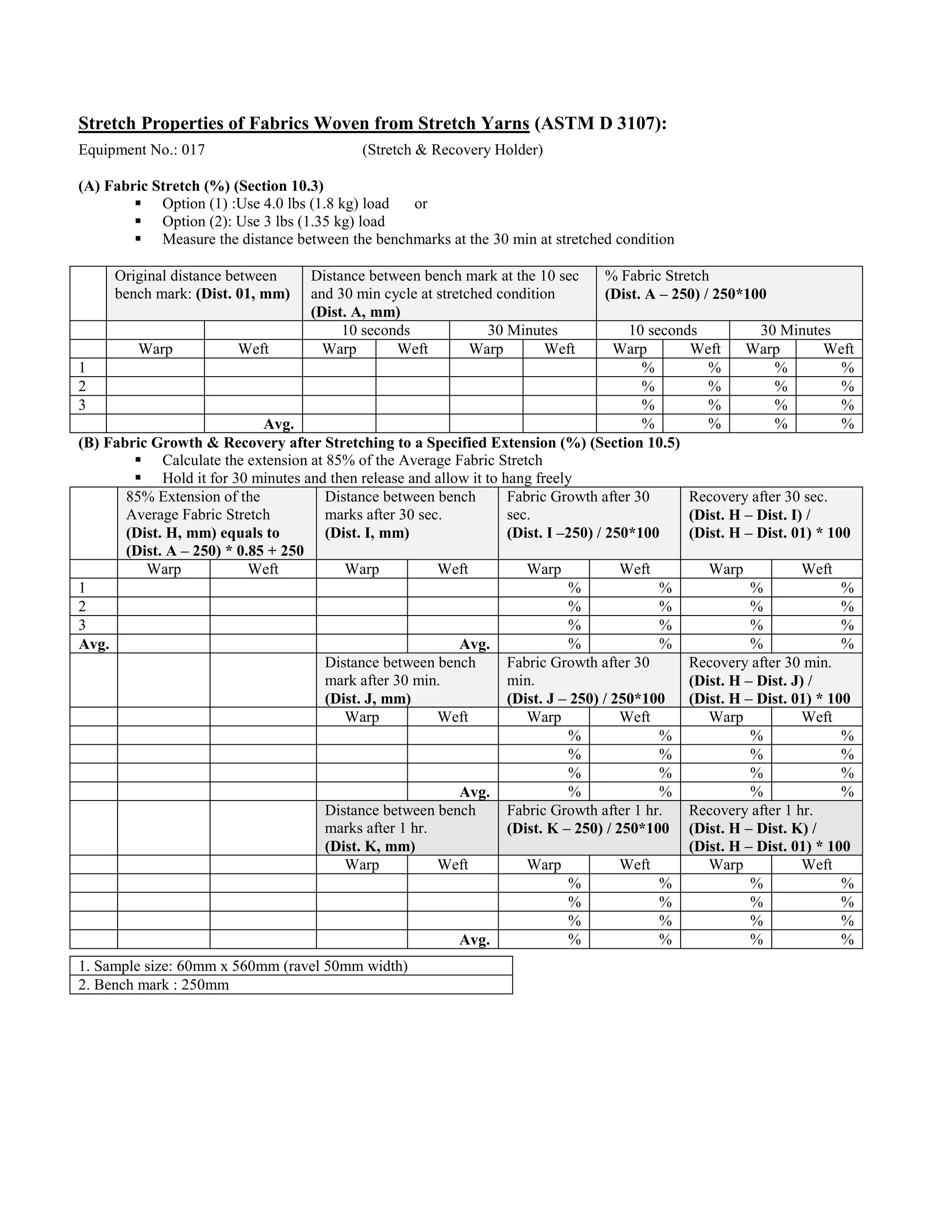

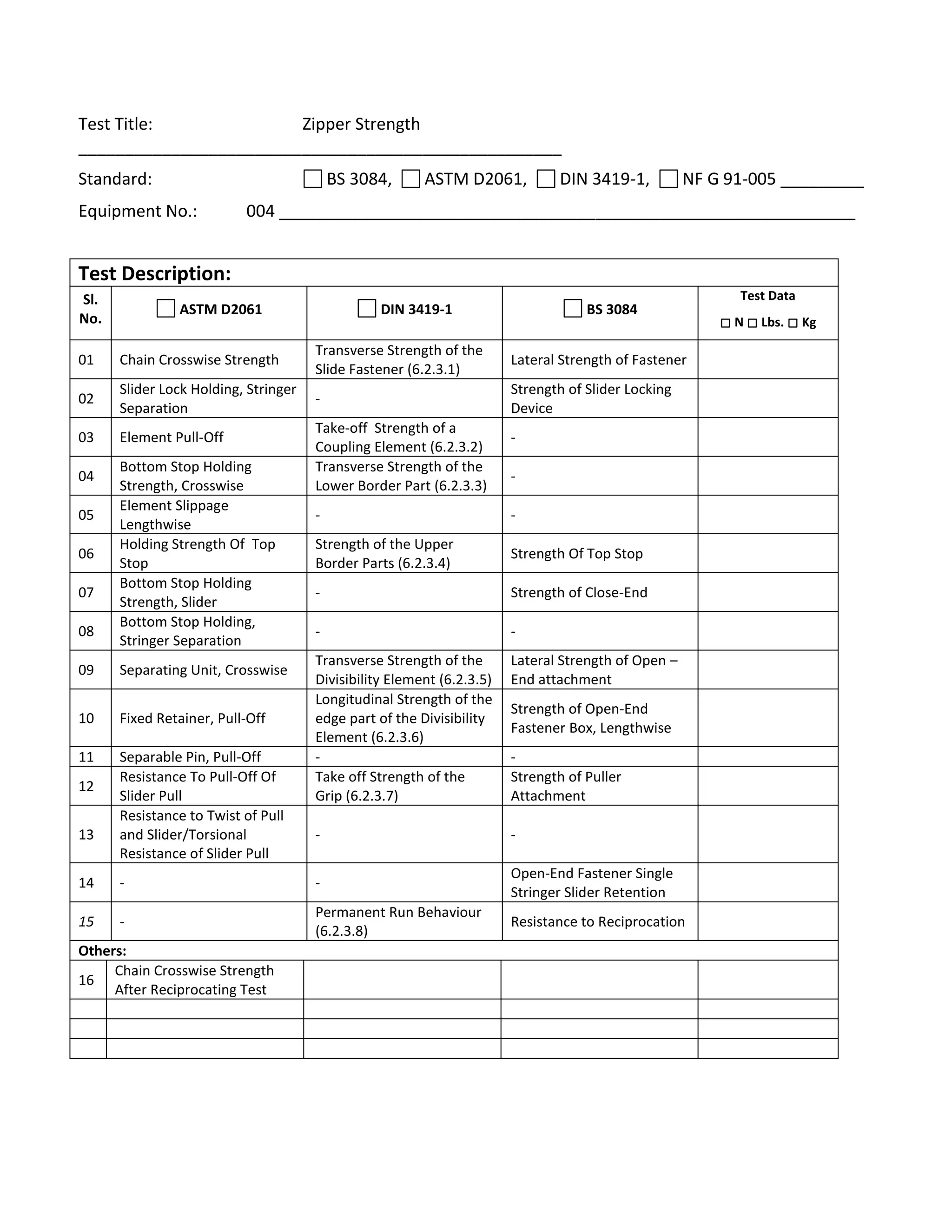

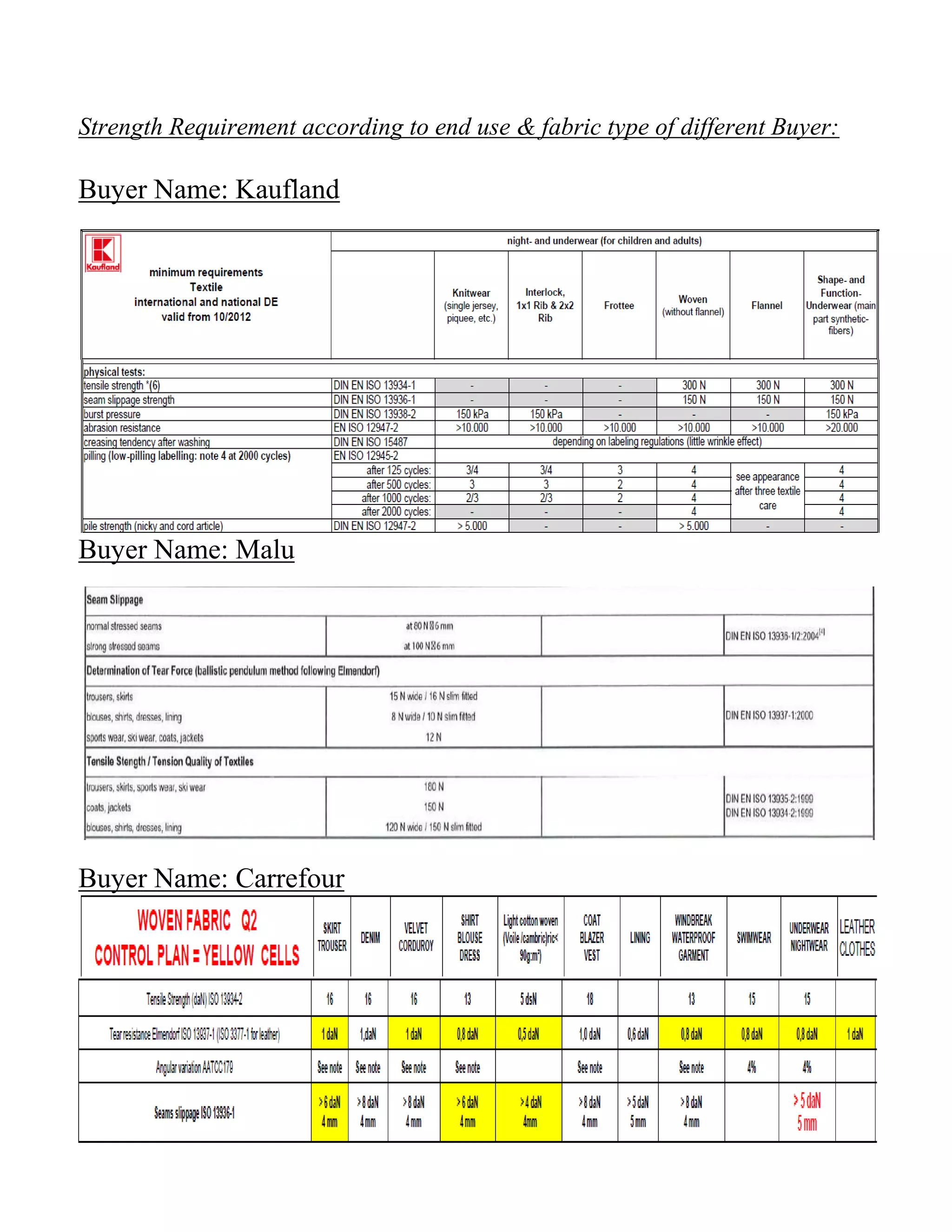

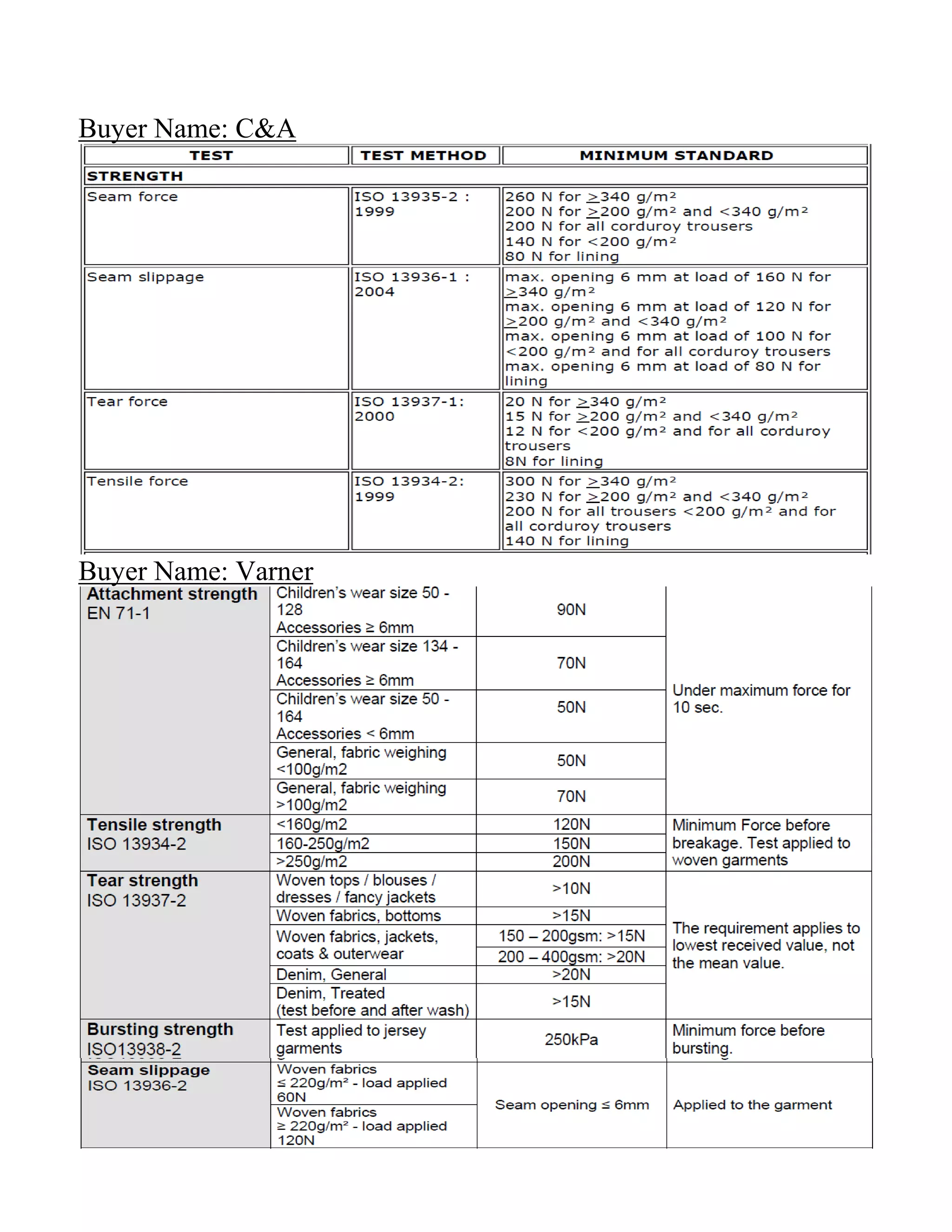

The document outlines the importance of textile testing and product quality in the apparel industry, detailing the processes and standards for evaluating various textile properties. It includes specific testing methods for tensile strength, tearing strength, bursting strength, and seam slippage, among others, highlighting the significance of these tests in assessing fabric performance. Comprehensive information on standards, test conditions, and allowable limits is also provided to ensure quality compliance.