1) In the 1830s, scientists discovered that the resistivity of metals changes with temperature, forming the basis of resistance thermometry.

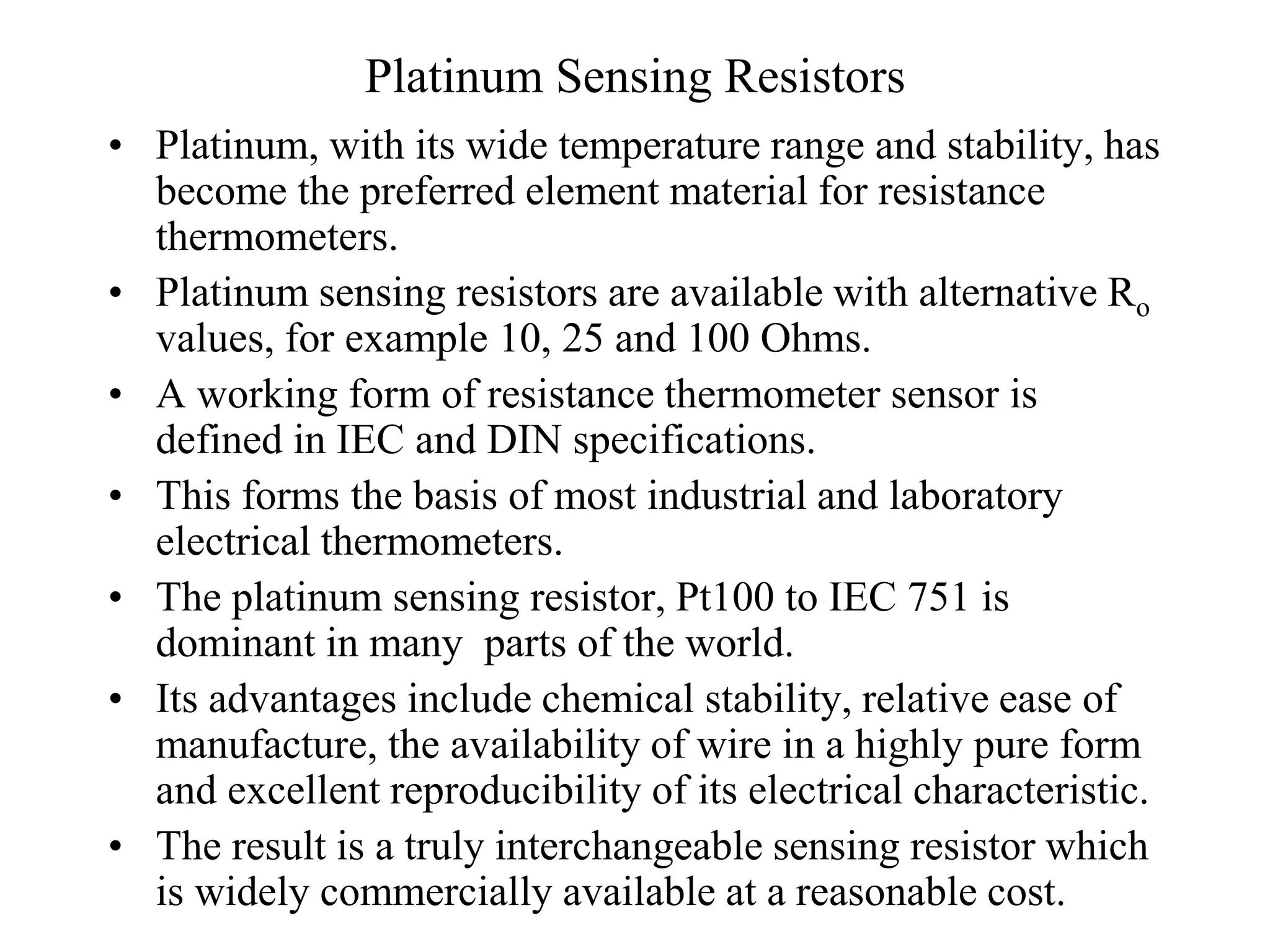

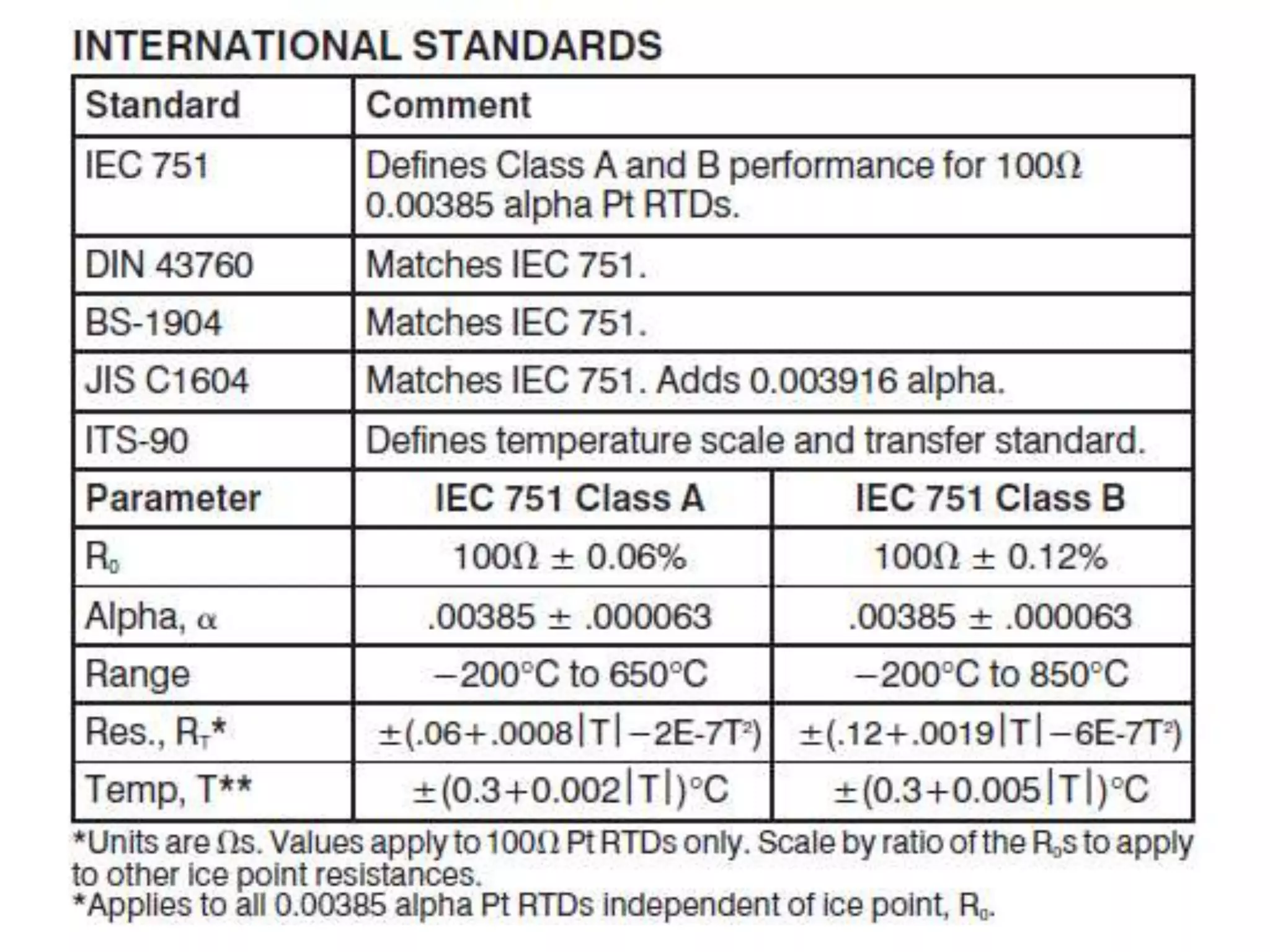

2) In the 1880s, platinum was proposed for use in resistance thermometers due to its stability, and it remains the primary element used today.

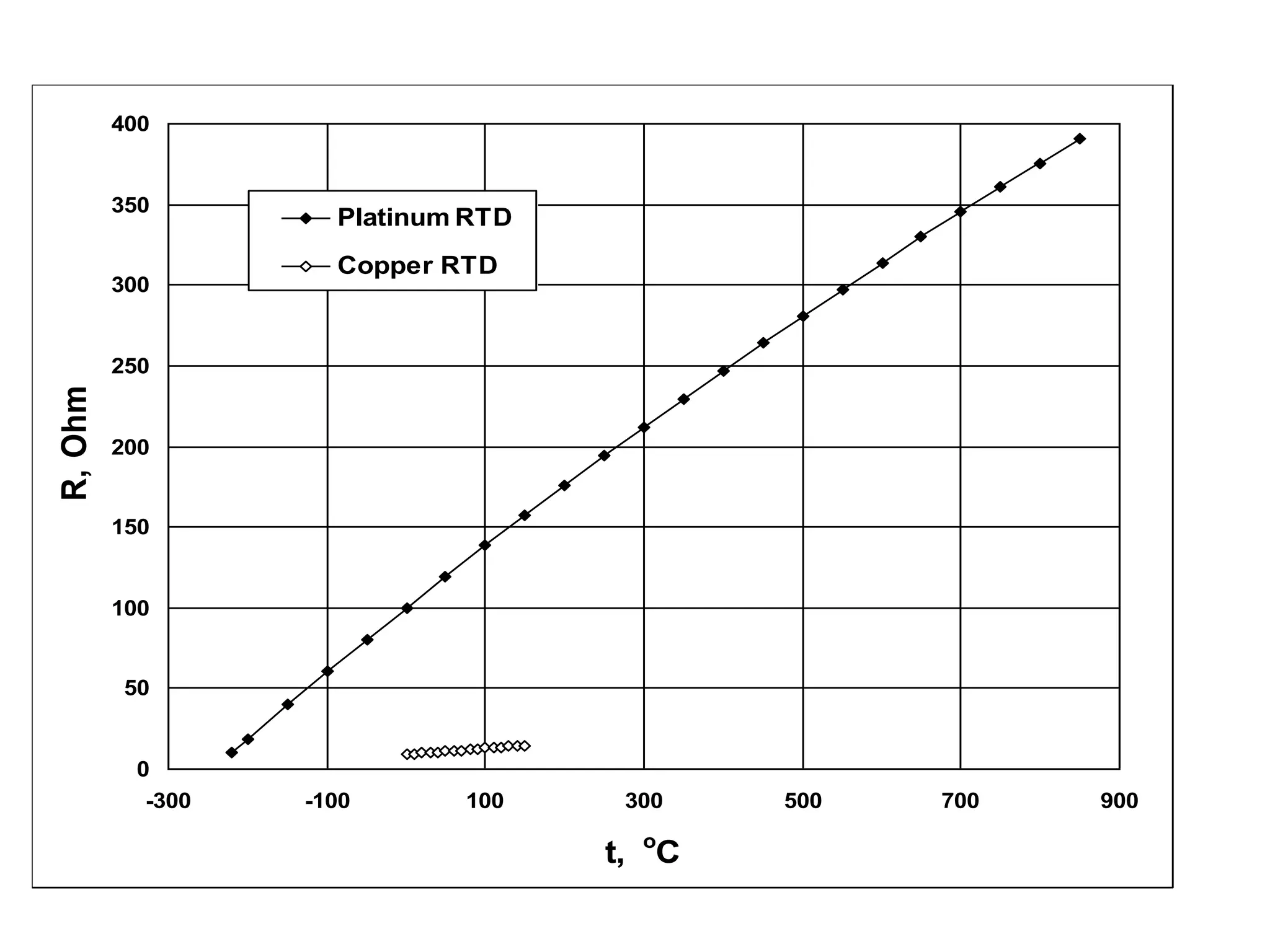

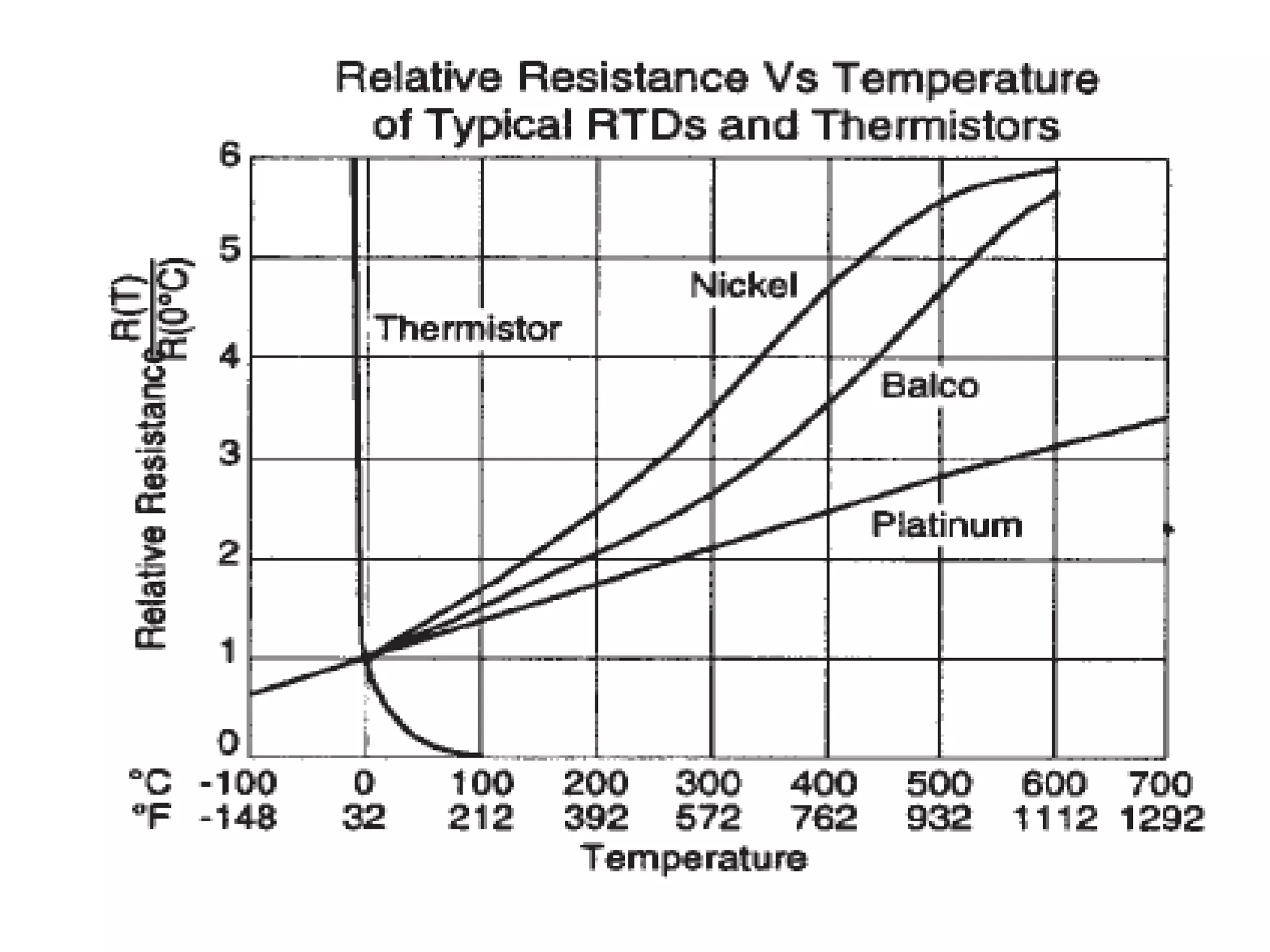

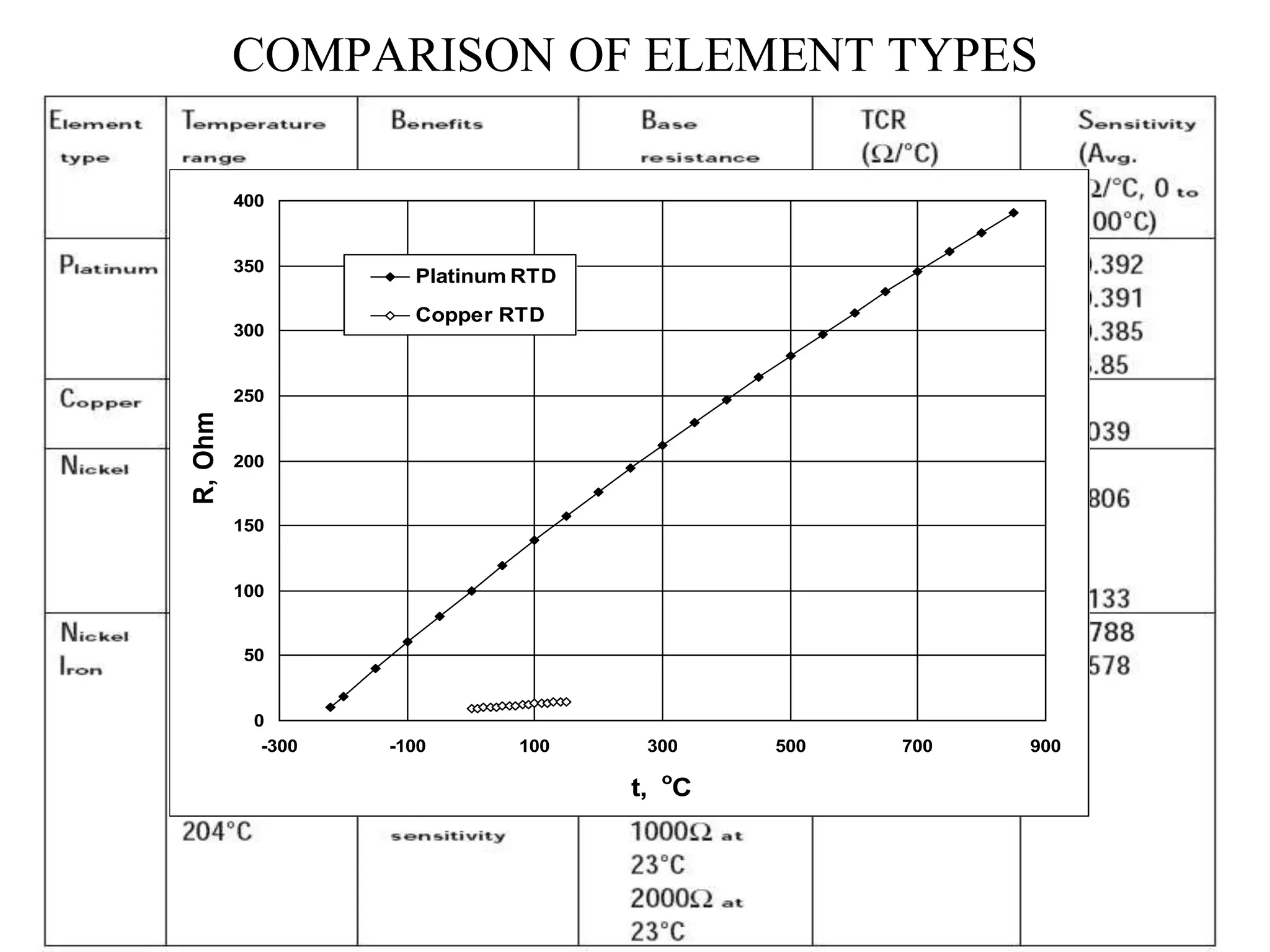

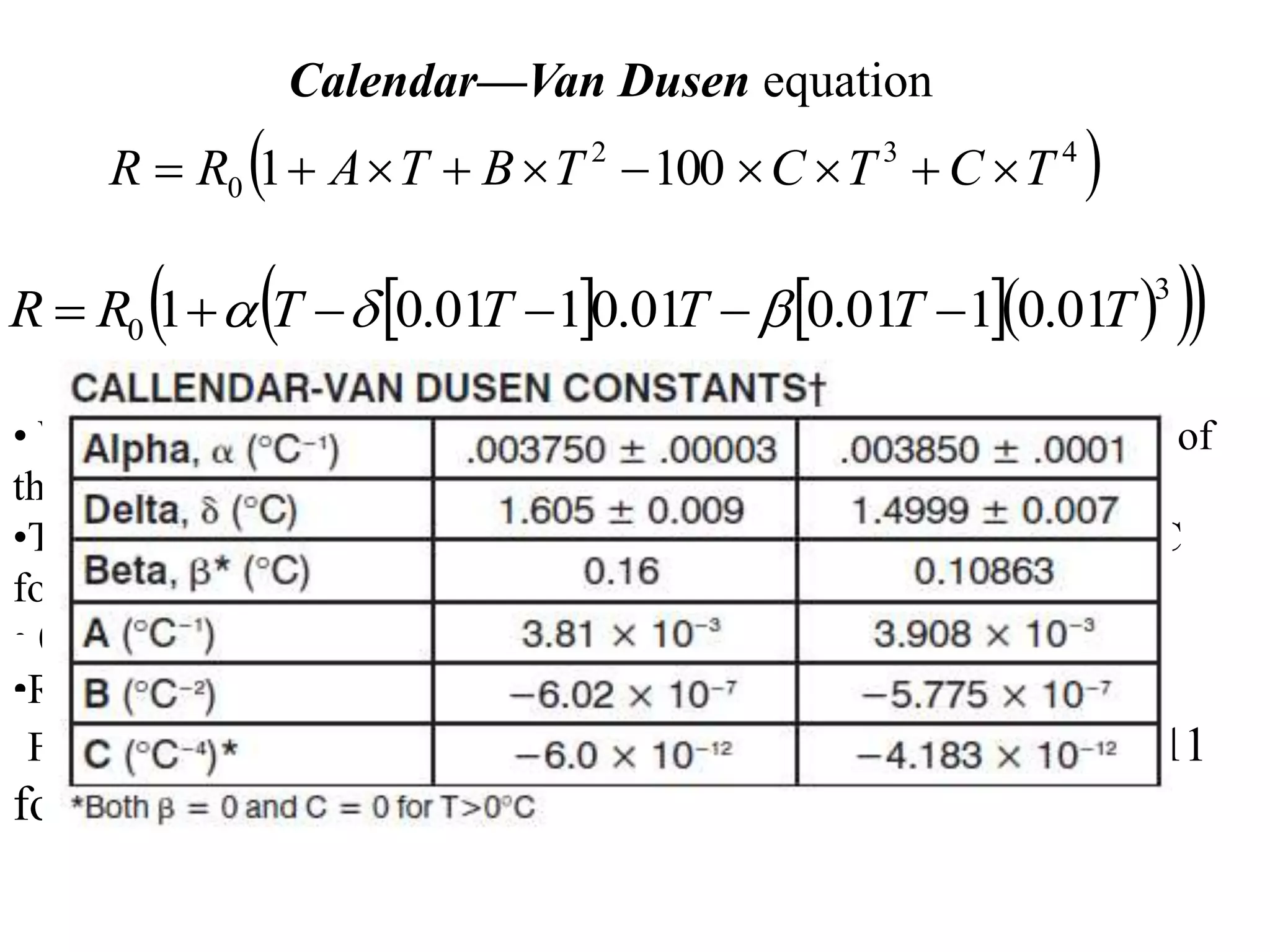

3) The relationship between temperature and electrical resistance in metals is nonlinear and described by polynomials, with platinum exhibiting a positive temperature coefficient of resistance.