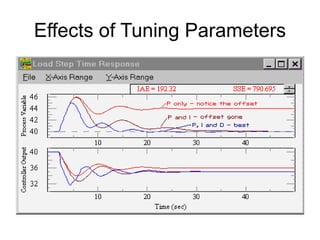

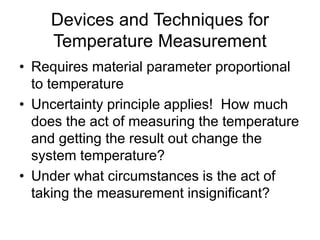

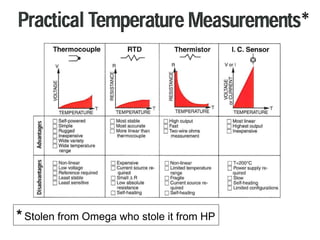

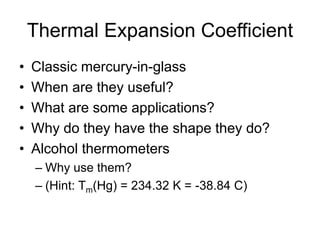

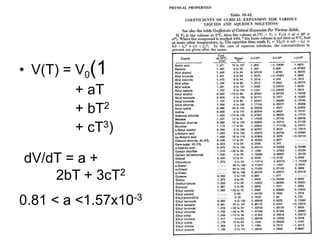

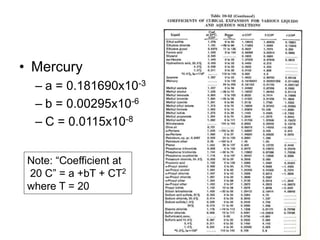

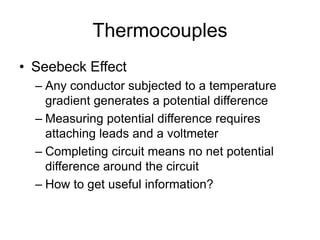

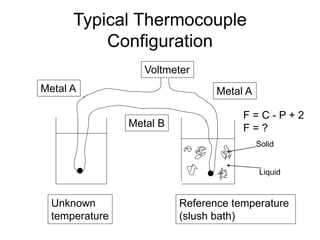

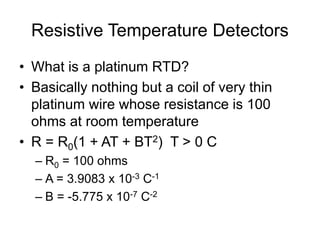

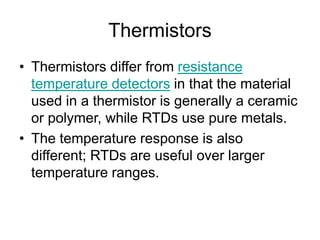

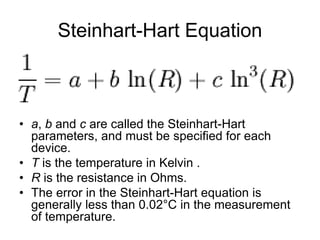

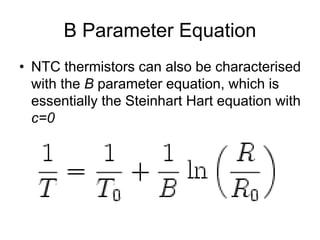

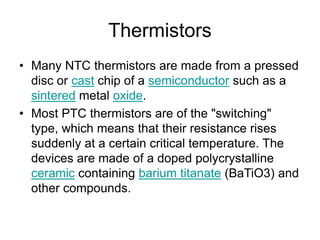

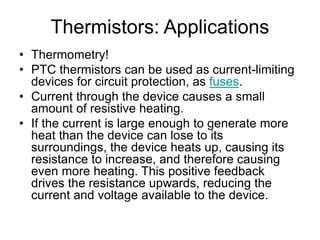

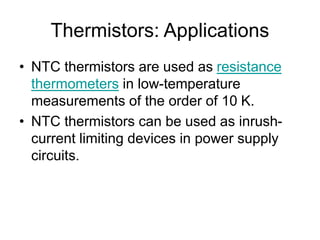

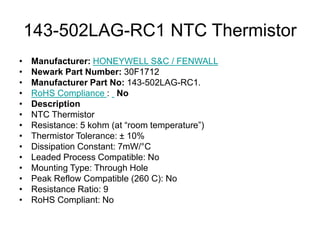

This document discusses various methods for temperature measurement and control. It defines temperature and describes applications for temperature measurement in physics experiments. It then covers different devices and techniques for temperature measurement, including expansion thermometers, thermocouples, resistive temperature detectors (RTDs), thermistors, and radiative methods like optical pyrometers and infrared thermometers. Specific thermocouple types and standards for platinum RTDs are outlined. Thin film and wire wound RTD construction is described. The Steinhart-Hart and B parameter equations for relating resistance to temperature in thermistors are provided. Finally, dissipation constant, thermal time constant, and resistance ratio characteristic for thermistors are defined and applications like current limiting and

![Thermocouple types

• Type E (chromel–constantan)[4] has a high

output (68 µV/°C) which makes it well suited to

cryogenic use. Additionally, it is non-magnetic.

• Type J (iron–constantan) is less popular than

type K due to its limited range (−40 to +750 °C).

The Curie point of the iron (770 °C) causes an

abrupt change to the characteristic and it is this

that provides the upper temperature limit. Type J

thermocouples have a sensitivity of about

50 µV/°C.[3]](https://image.slidesharecdn.com/temperaturemeasurement-200821070850/85/Temperature-Measurement-16-320.jpg)

![Terminology

• Controller (temperature): A device that

makes continuous operator attention and

input unnecessary.

• Examples

– Cruise control on car

– Fill valve in your toilet tank

– Thermostat in your house

• This is an example of one simple type of

temperature controller: “On-off”

• Contrast with “temperature controller” on your [gas]

barbeque!](https://image.slidesharecdn.com/temperaturemeasurement-200821070850/85/Temperature-Measurement-36-320.jpg)