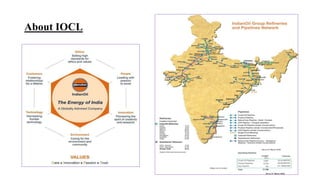

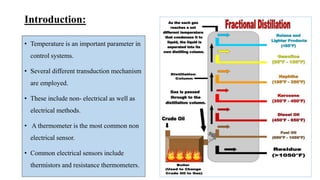

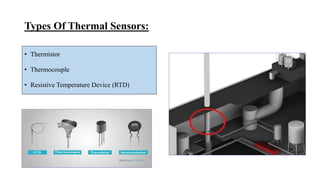

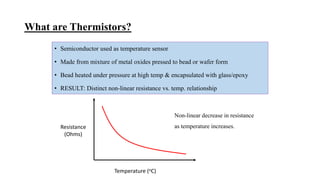

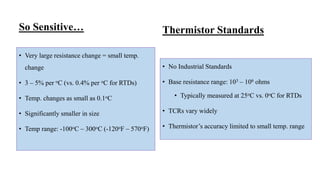

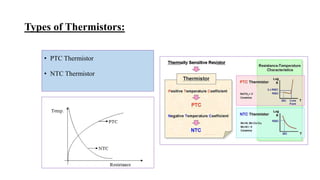

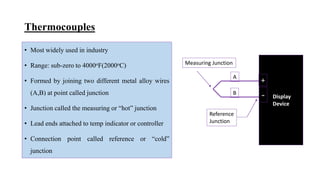

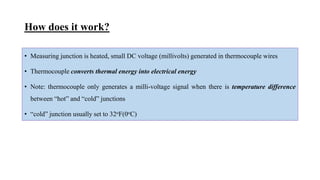

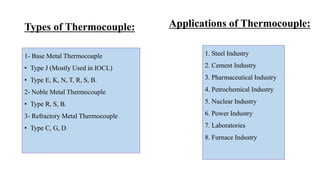

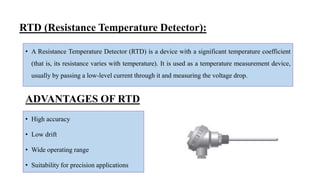

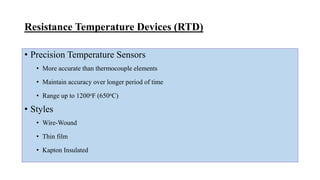

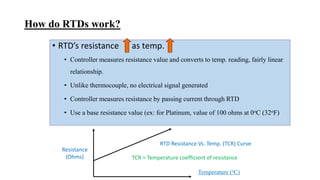

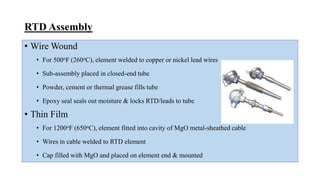

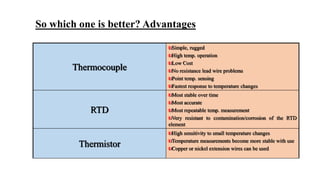

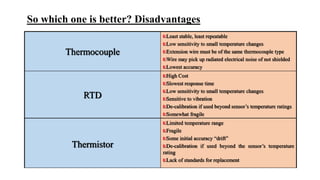

The document discusses temperature measurement of crude oil using thermal sensors. It provides an overview of Indian Oil Corporation and different types of thermal sensors like thermistors, thermocouples, and RTDs. Thermocouples are most widely used in industry due to their low cost and wide temperature range, while RTDs offer higher accuracy but are more expensive. Each sensor type has advantages and limitations for different industrial applications like petrochemical plants. Accurate temperature measurement is important for process control and quality assurance.