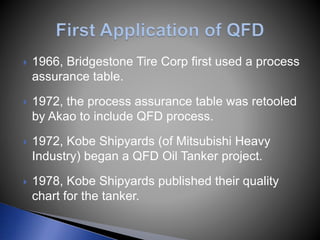

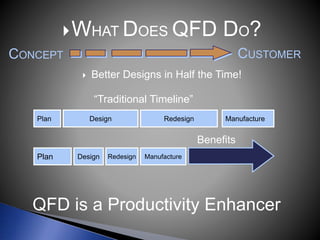

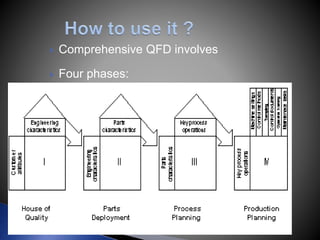

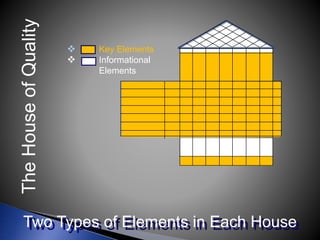

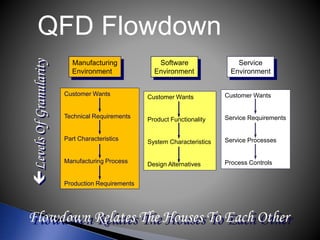

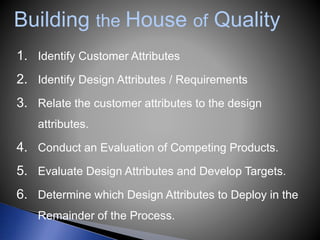

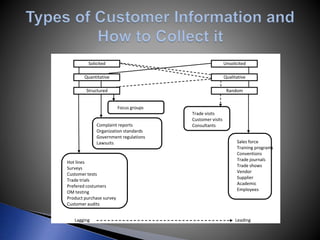

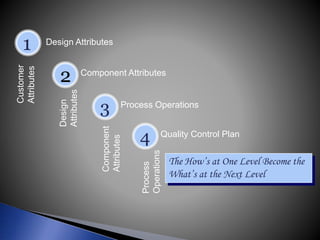

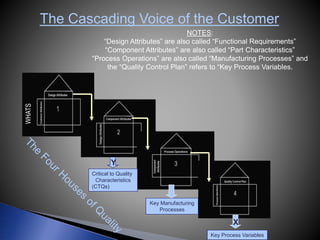

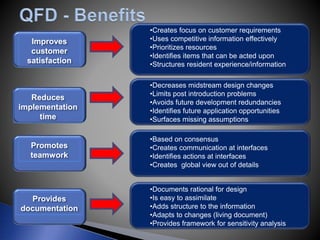

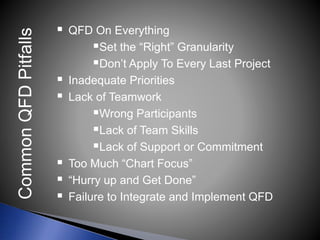

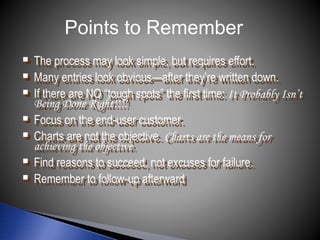

The document provides a comprehensive overview of Quality Function Deployment (QFD), detailing its history, purpose, and methodology in improving product design by incorporating the voice of the customer. It outlines the QFD process, including the 'House of Quality,' and highlights the benefits of cross-functional teamwork and systematic documentation in product development. The document emphasizes the importance of aligning customer needs with design attributes to enhance customer satisfaction and streamline production processes.