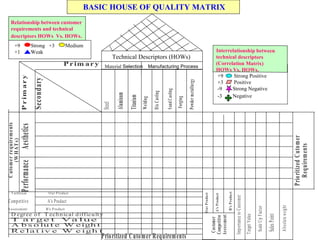

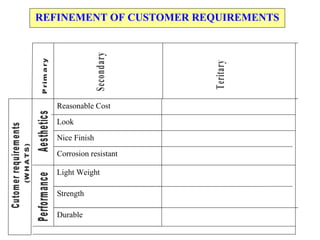

Quality Function Deployment (QFD) is a systematic approach to product development that focuses on understanding customer needs and using that information to ensure that these needs are addressed at each stage of development. QFD has four phases: product planning, part deployment, process planning, and production planning. It provides benefits such as being customer-driven, reducing implementation time, promoting teamwork, and providing documentation to support design decisions. The core of QFD is creating a house of quality matrix that links customer needs to technical requirements using a correlation matrix.