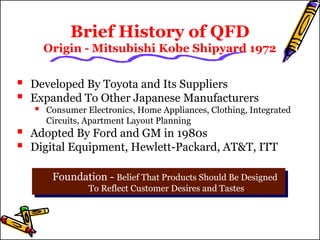

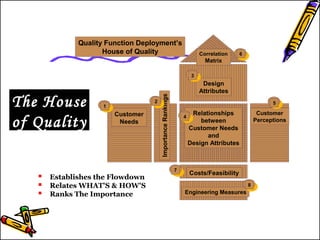

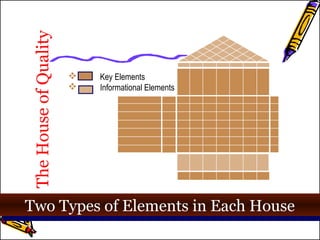

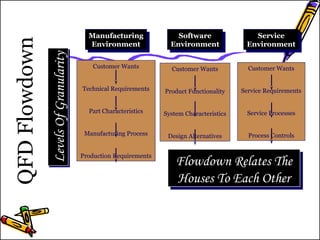

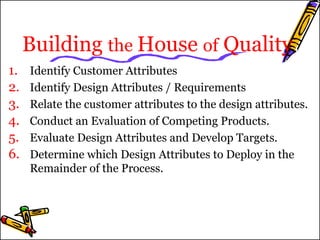

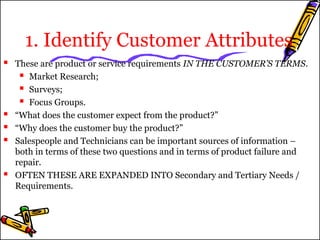

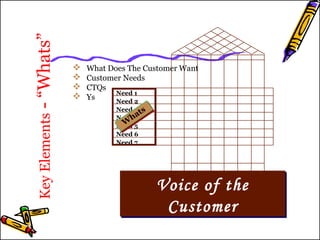

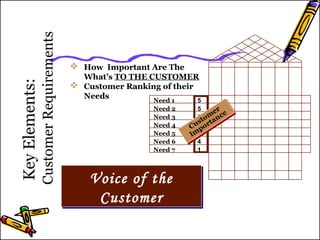

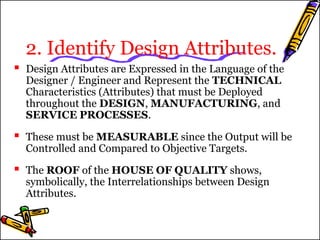

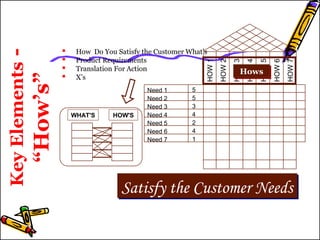

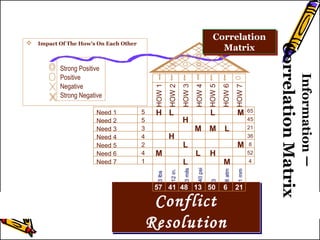

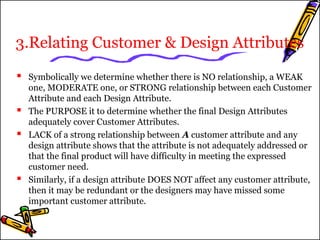

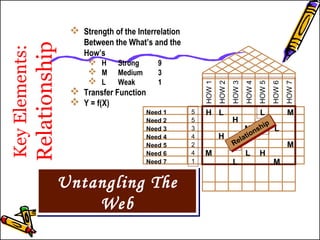

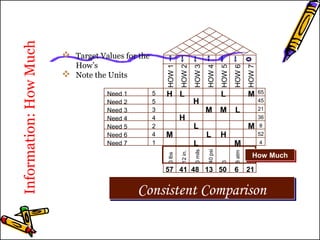

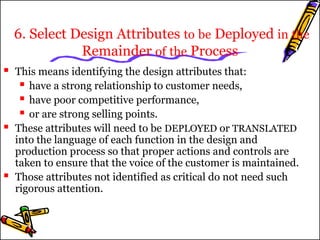

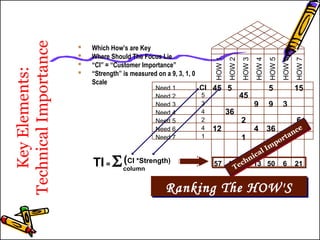

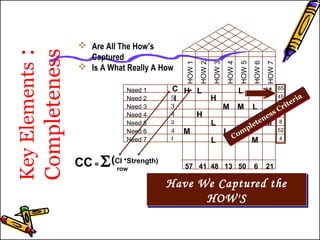

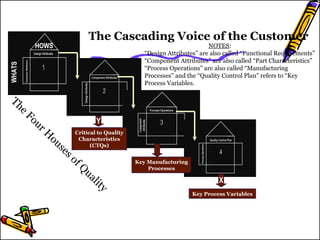

The document provides an overview of Quality Function Deployment (QFD). QFD is a structured method used to translate customer requirements into technical requirements and product characteristics throughout the development process. It uses a tool called the "House of Quality" which maps customer needs, technical requirements, and their relationships. The House of Quality allows companies to focus design and development efforts on what matters most to customers. It can result in fewer design changes, start-up problems, shorter development times and lower costs.