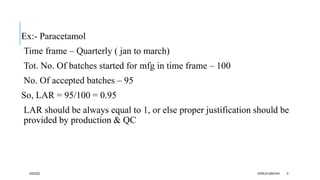

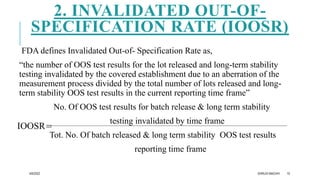

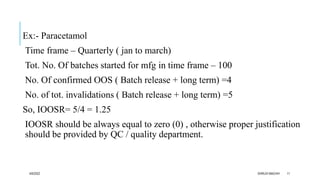

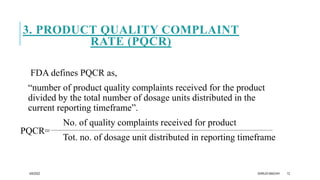

The document discusses quality metrics that are used in the pharmaceutical industry to monitor quality control systems and processes. It defines three key quality metrics that the FDA intends to calculate: (1) Lot Acceptance Rate (LAR), which measures the number of accepted lots versus total lots started; (2) Invalidated Out-of-Specification Rate (IOOSR), which measures invalidated out-of-specification test results versus total out-of-specification results; and (3) Product Quality Complaint Rate (PQCR), which measures the number of quality complaints received versus total units distributed. Quality metrics are important to ensure acceptable product quality and assess performance and improvements.