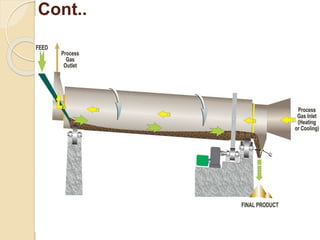

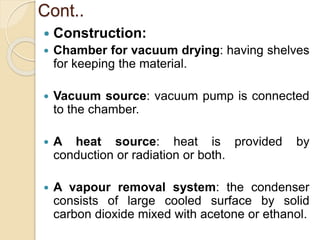

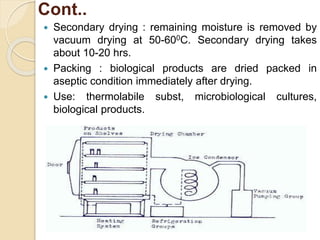

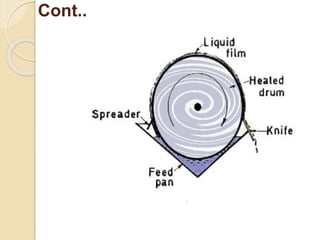

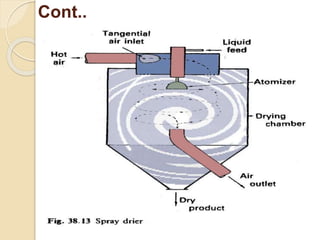

This document provides an introduction to various drying processes. It discusses that drying involves both heat and mass transfer operations to remove liquid from solids. Common drying equipment includes tray dryers, tunnel dryers, rotary dryers, fluidized bed dryers, vacuum dryers, freeze dryers, drum dryers, and spray dryers. Each type of dryer has a different design and is suited for specific drying applications and material types. The document also provides details on the theory, working, and uses of some common drying equipment.