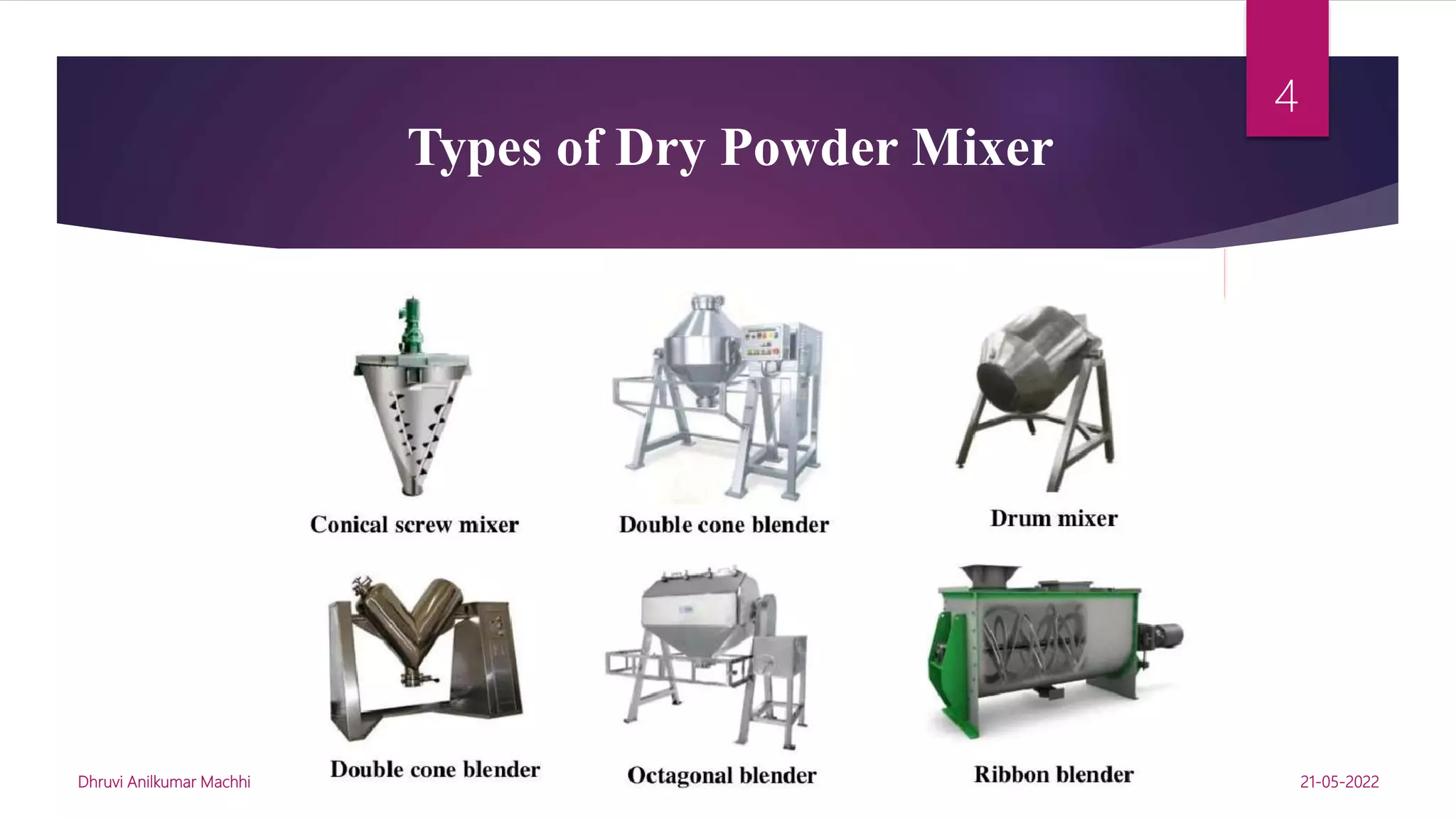

The document discusses the qualification process of dry powder mixers within pharmaceutical validation, outlining the types of mixers, and the qualifications required: design, installation, operational, and performance. It emphasizes the importance of proper mixing in achieving content uniformity in solid dosage forms, detailing monitoring variables like blend uniformity, RPM, and mixing time. References for further reading are provided to support the discussed concepts.