Textile testing is an important part of the textile production process. It involves determining various properties of fibers, yarns, and fabrics to ensure quality standards are met. The objectives of textile testing include selecting raw materials, controlling manufacturing processes, ensuring quality of finished products, and facilitating research and product development. There are different types of textile testing for fibers, yarns, woven fabrics, knitted fabrics, and nonwoven fabrics. Test methods are established by various standards organizations and influence factors like sampling methods, atmospheric conditions, equipment used, and technician skill.

![1

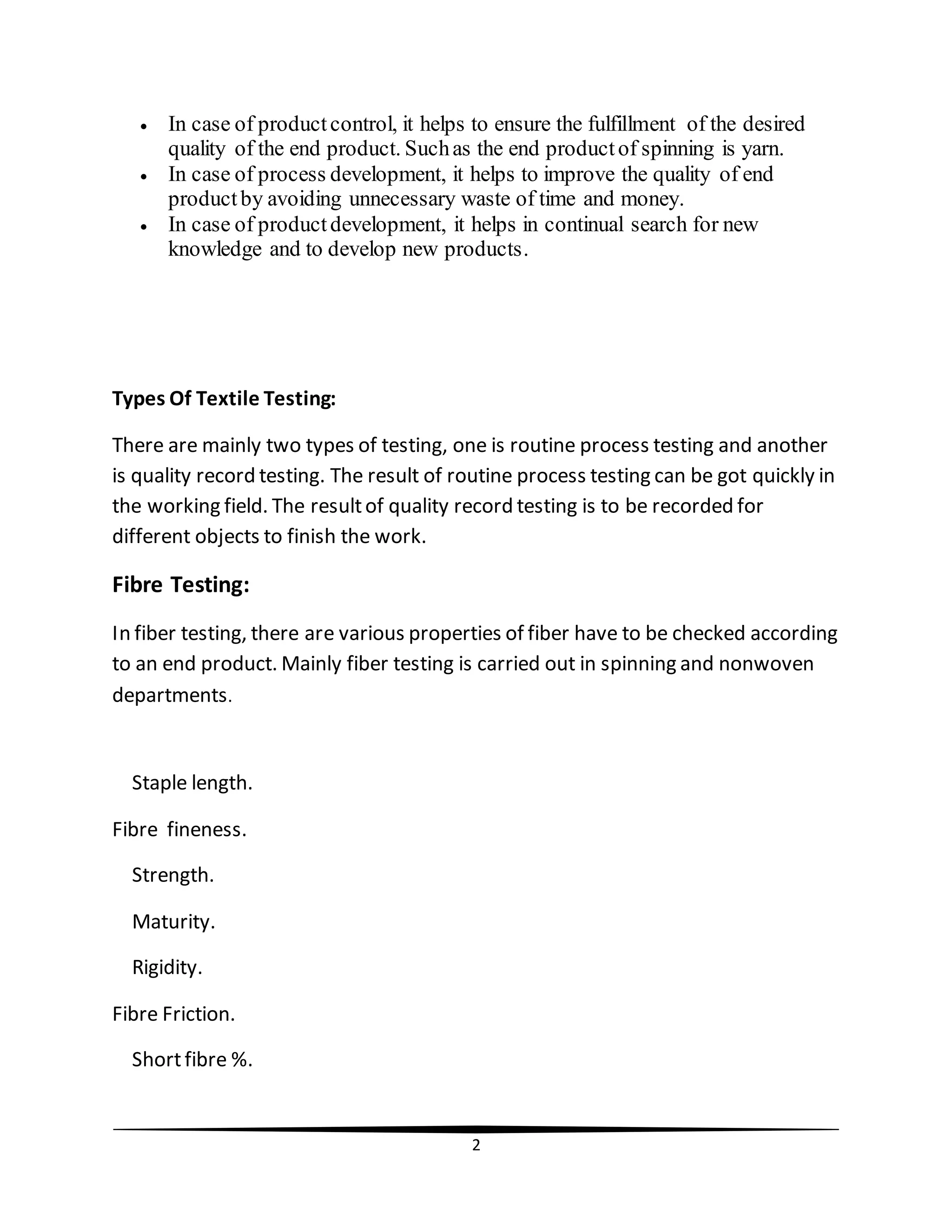

Introduction:

Textile Testing is an important part for textile production, distribution, and

consumption. We can also define Textile Testing as the process of determining the

properties of different kinds of Textile substances. The primary purpose of textile

testing and analysis is to assess textile product performance and to use test results

to make predictions about product performance. Product performance must be

considered in conjunction with end use; therefore, tests are performed with the

ultimate end use in mind. Examples of testing for end-use performance include

testing draperies for light fastness or tire cords for strength. [1]

What is Testing?

Testing is the way of control or the process to check or verify the nature, kind or

character of fiber, yarn, fabric or any material, hence control the degree of

excellence.

Now, testing may be different type

Fiber- length, strength, fineness, maturity.

Yarn- strength, count, twist

Fabric- EPI, PPI, GSM. [2]

Objects of textile testing:

The objectives of Textile Testing are as follows –

In case of research, the results of testing will help the scientist to decide

which route should be followed.

It helps to select the properraw materials. Raw material is a relative term.

As for example, fibre is the raw material of spinner, yarn is the raw material

of weaver etc.

Textile Testing helps to controlthe different processes. Suchas Spinning,

Weaving, Dyeing, Finishing etc. End breakage is controlled by controlling

weight per lap length, sliver length and roving length. Weaving process is

controlled by controlling the excessive breakage of warp and weft yarn.

Dyeing process is controlled by M : L, temperature and pressure.](https://image.slidesharecdn.com/importantoftextiletesting-171221124123/75/Important-of-textile-testing-1-2048.jpg)

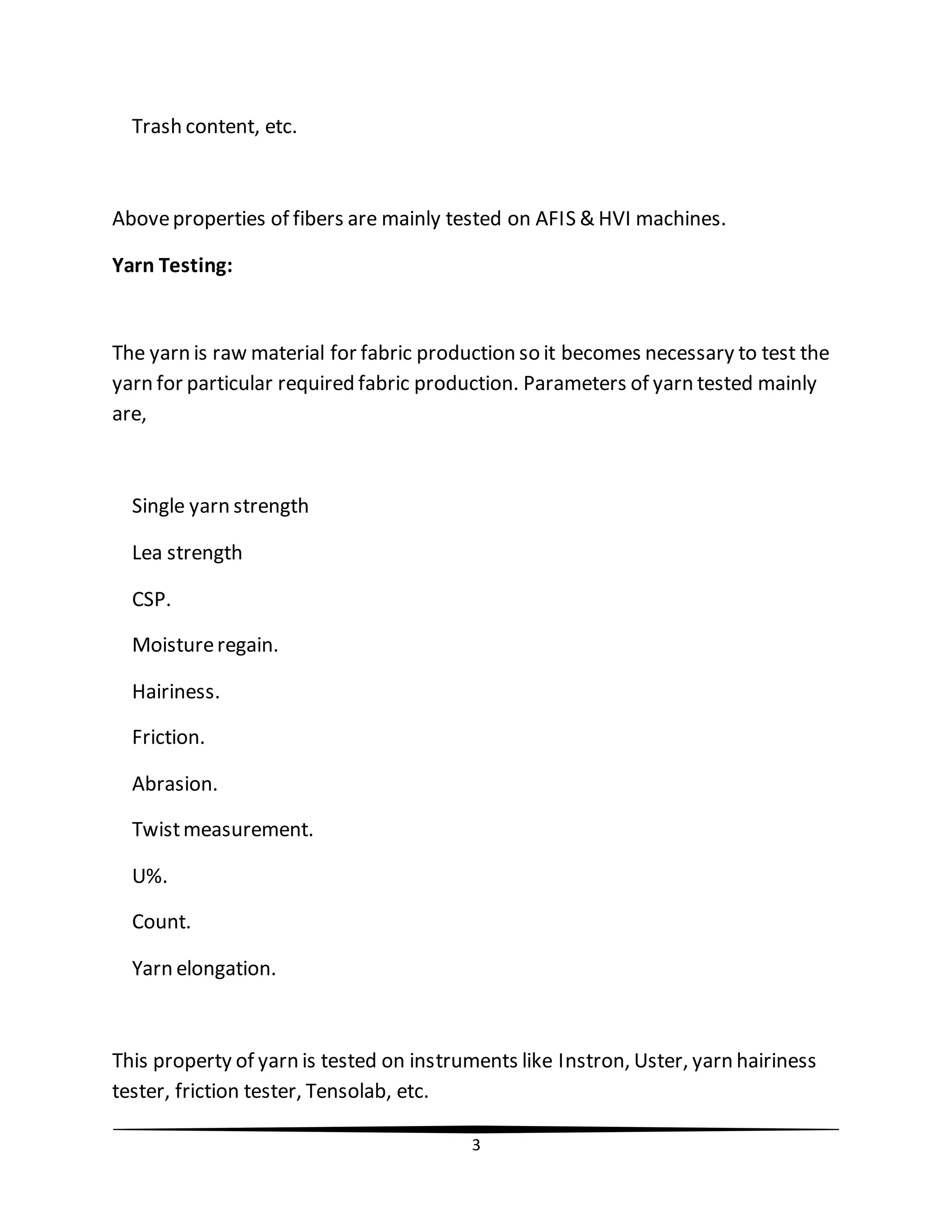

![4

Fabric Testing (Woven, Knitted & Nonwoven)

Our ultimate aim is to achieve optimum quality fabric. So to check whether the

quality is achieved or not testing of fabric is done.

Tensile strength.

GSM.

Pilling tendency.

Abrasion.

Drapeability or hanging property.

Moisture%.

Cover factor.

Creaserecovery and creaseresistance.

Stiffness.

Air permeability.

Shrinkage, etc.

All these testing is done after conditioning of material and in standard

atmospheric conditions.[4]](https://image.slidesharecdn.com/importantoftextiletesting-171221124123/75/Important-of-textile-testing-4-2048.jpg)

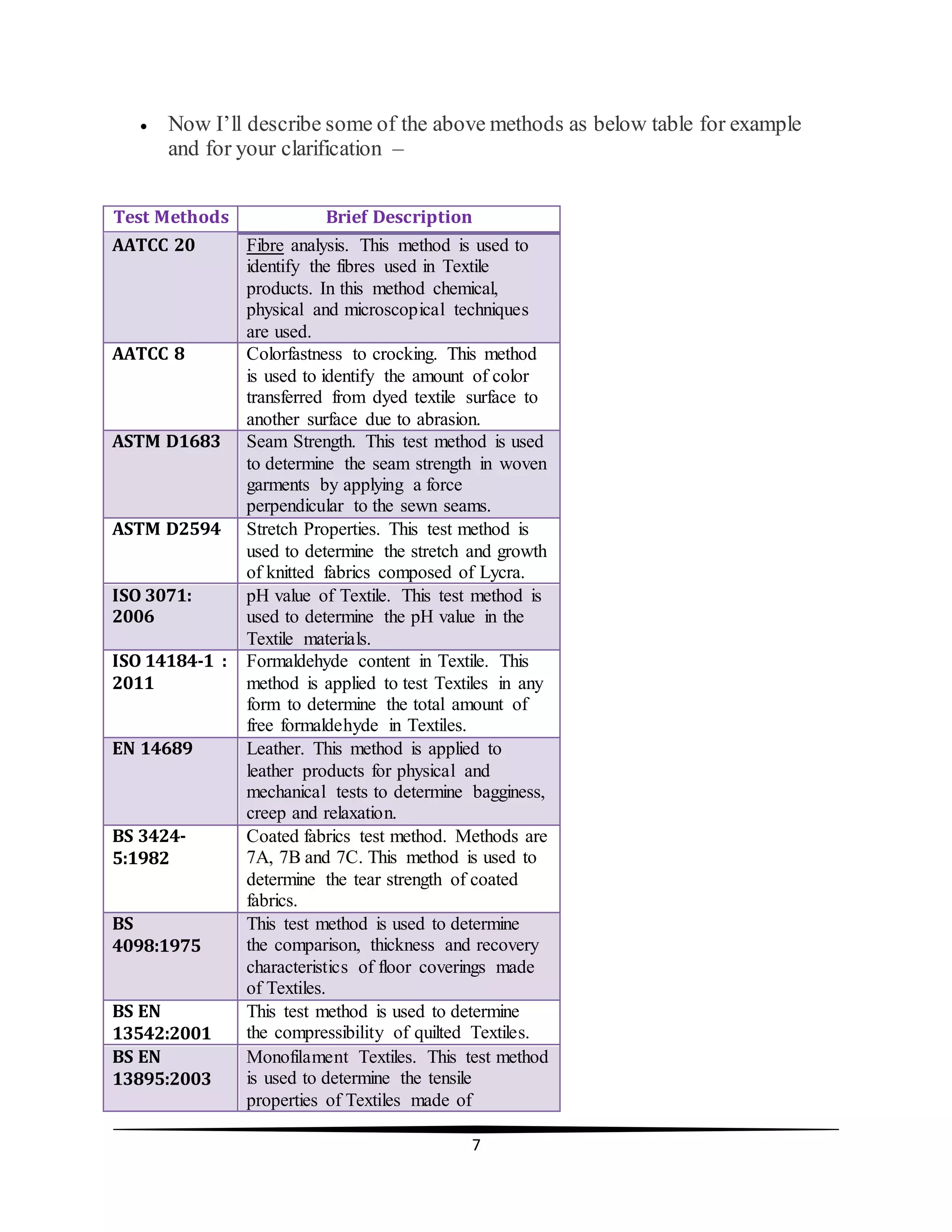

![5

Importance of Textile Testing:

1. Research Work: Test of the textiles helps the authority to decide the next

route.

2. Selection of Raw Materials: During textiles testing the variation of a fibre or

fabric i.e. length, color, fineness (in case of textile fibre), threads per inch, cover

factor (in case of textile fabric), is detected properly. Thus proper raw materials

are selected properly.

3. Process Control: Certain standard level should be maintained to control

increase of waste, rise of costetc. By textile testing we can easily detect the faults

of machinery and materials during test of textiles.

4. Process Development: Research Institute, pilot plants can achieve process

development through testing or exact investigation into better, cheaper and

quicker methods.

5. Search for effective productivity: Continuous test of the textiles results a

enhanced and efficient output of the production.

6. Specification Test: To meet up the customer requirement, specification is very

useful. In this concept, testing plays a vital role.[5]

Factors affecting testresults:

-The sampling

-Atmospheric condition during testing

-Methods of testing

-Instruments used

-Efficiency of the technician[2]](https://image.slidesharecdn.com/importantoftextiletesting-171221124123/75/Important-of-textile-testing-5-2048.jpg)

![6

Some important testing standards:

AATCC: American Association of Textile Chemists & Colorists

ASTM: American Society for Testing & Materials

ISO: International Organization for Standardization

BSTI: Bangladesh Standards & Testing Institution

WIRA: The Wool Industries Research Association

AS: Australian Standard

BSI: British Standards Institution [2]

Moisture in case oftesting

Most textile fibers are hygroscopic, i.e. they have the ability to absorb or give up

moisture. This moisture is picked up or absorbed bythe hygroscopic material from

the atmosphere if the relative amount of moisture in the air is greater than that in

the material. Conversely, the moisture will be given up by the material if the

relative amount of moisture in the air is less than that in the material.

Many physical properties of a fiber are affected by the amount of water absorbed,

such as dimensions, tensile strength, elastic recovery, electrical resistance and so

on. [2]

Different Types OfTextile Testing Methods

Different buyers usedifferent Textile testing methods. There are different types of

Textile and Garments Testing methods such as –

American Society of Testing &Materials (ASTM)

American Association of Textile Chemists and Colorists (AATCC)

International Organization for Standardization (ISO)

European Norms (EN)

British Standards (BS)

British Standards for European Nations (BS EN)

DeutschesInstitut fur Normung (DIN)

Bureau of Indian Standards (BIS)](https://image.slidesharecdn.com/importantoftextiletesting-171221124123/75/Important-of-textile-testing-6-2048.jpg)

![8

[10]

Conclusion:

Testing means checking, examine and verification of some items. On the other

way we can define testing as; it is the process or procedureto determines the

quality of a product.

Reference:

1: https://textileapex.blogspot.com/2015/10/what-is-textile-testing-definition.html

2/7/8/9: http://textilequalitytest.blogspot.com/

4: http://textilelearner.blogspot.com/2012/02/textile-testing-objects-of-textile.html

5 :http://www.testextextile.com/textile-testing-importance-of-testing-in-textiles/

10: https://textileapex.blogspot.com/2016/06/textile-testing-methods.html

monofilament yarns.

BS EN ISO

9073-4:1997

Non-woven Textiles. This test method is

used to determine the tear resistance of

Non-Woven Textiles.

BS EN ISO

105-

E01:2013

Colorfastness to water. This test method

is used to define the amount of color

transferred from dyed textiles in

presence of water.

JIS L

1041:2011

Formaldehyde content in Textiles. This

test method is used to determine the

amount of formaldehyde content in

Textiles.](https://image.slidesharecdn.com/importantoftextiletesting-171221124123/75/Important-of-textile-testing-8-2048.jpg)