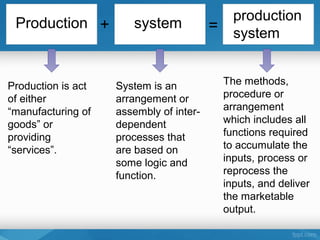

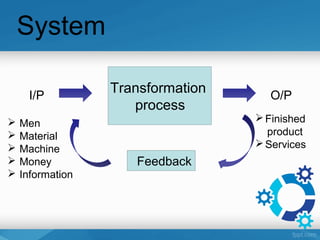

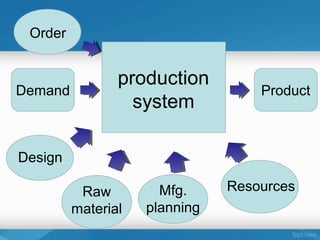

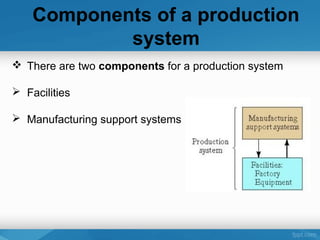

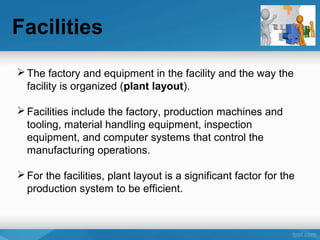

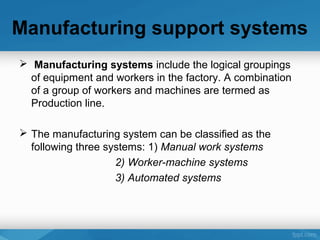

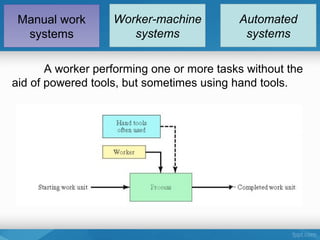

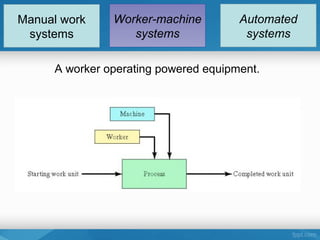

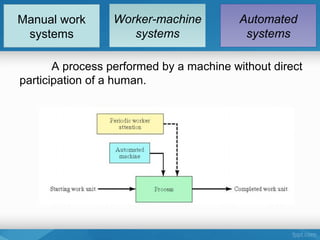

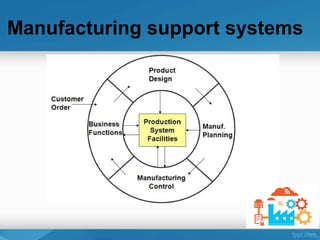

The document defines and describes the components of a production system. A production system combines various inputs like materials, labor, machines, and information and transforms them through a process to produce finished goods and services. The key components are facilities, which include the factory, equipment, and layout, and manufacturing support systems, which encompass how work and machines are organized. The aim of a production system is to provide the right products, in the proper quantities, at the needed time and location, and at a reasonable cost.