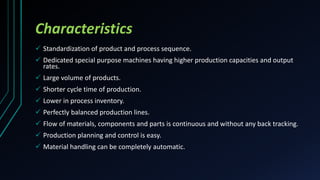

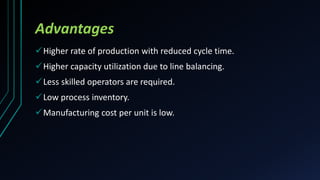

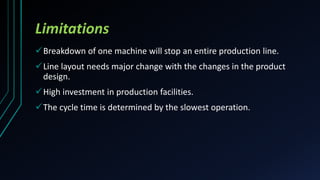

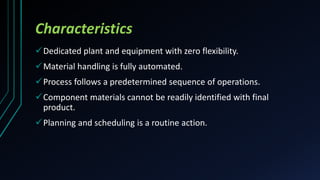

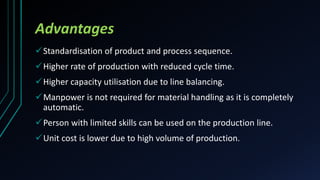

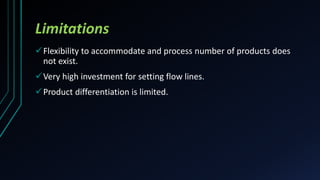

This document provides an overview of operations management concepts, including different types of production systems. It discusses job shop production, batch production, mass production, and continuous production. Job shop production involves manufacturing low volumes of customized products using general purpose machines. Batch production produces limited numbers of products in batches. Mass production uses dedicated machines and standardized processes for high-volume output. Continuous production arranges facilities in a linear sequence to enable fully automated material flow.