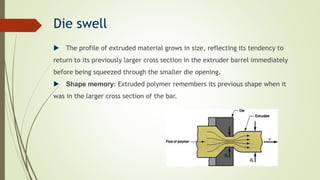

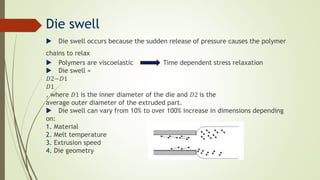

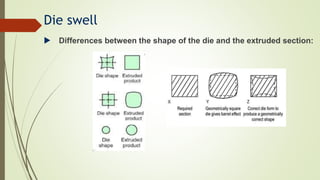

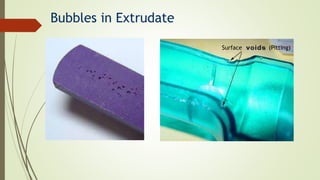

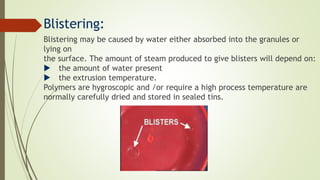

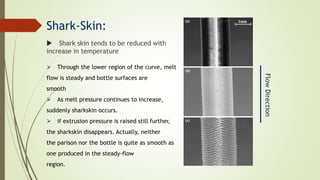

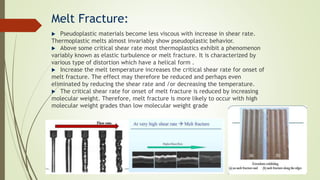

The document discusses common defects and troubleshooting methods related to the extrusion process, focusing on issues like die swell, blistering, lumpiness, shark skin, melt fracture, black lumps, knitting errors, and plate-out. It explains how these defects occur, their causes, and potential solutions such as adjusting extrusion rates, die geometry, and temperatures. Overall, it emphasizes the importance of careful processing and material handling to minimize defects during polymer extrusion.