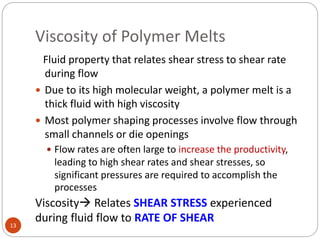

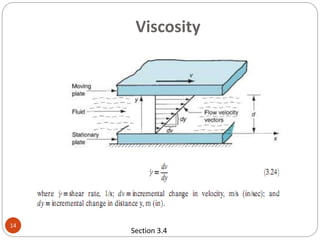

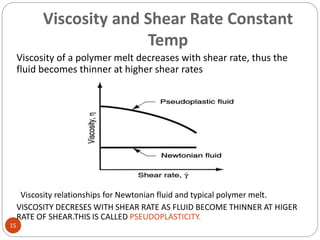

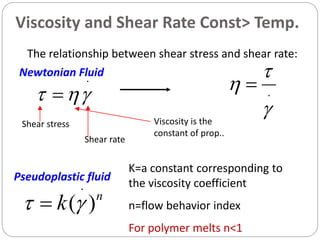

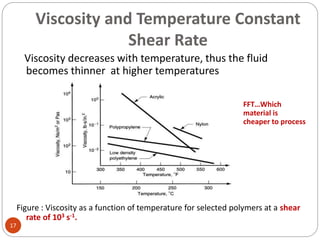

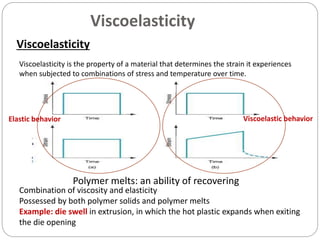

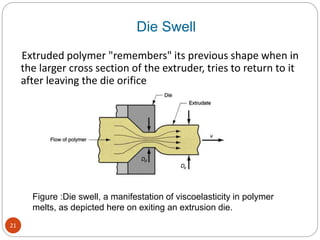

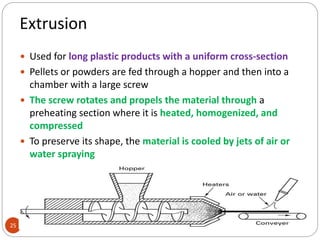

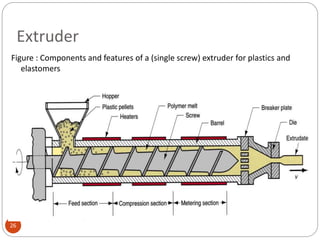

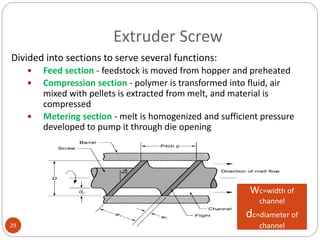

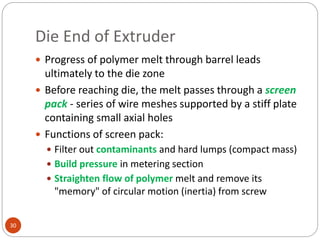

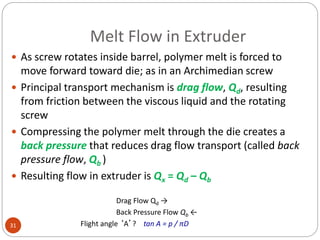

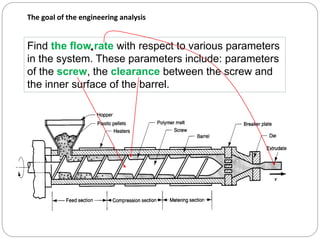

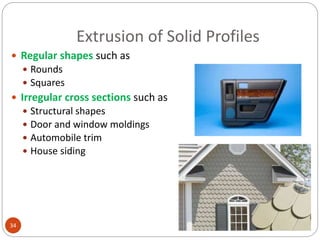

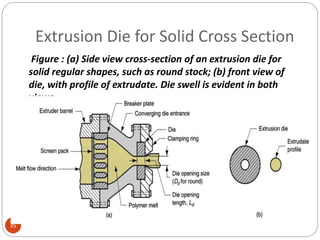

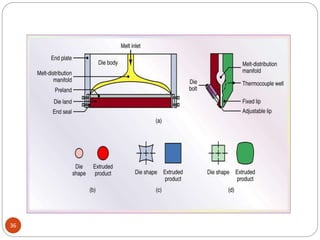

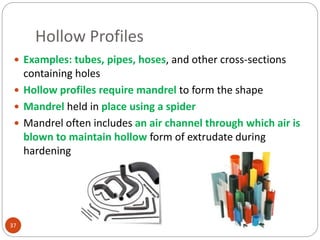

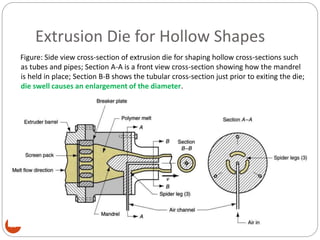

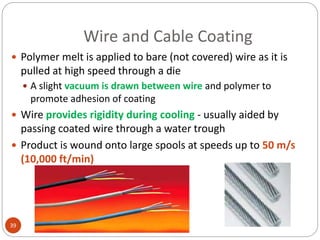

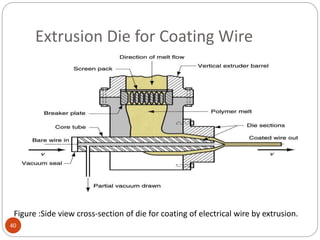

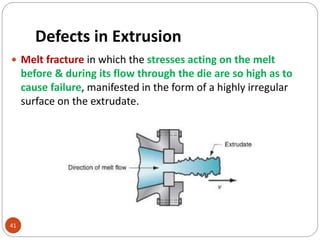

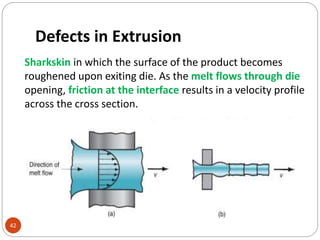

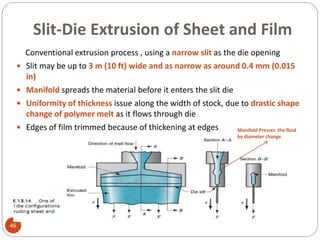

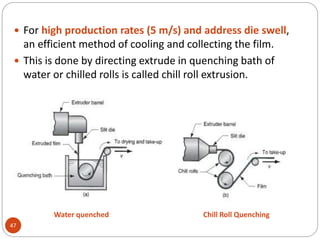

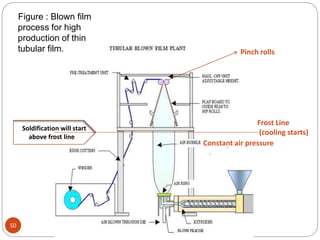

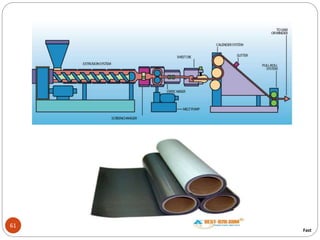

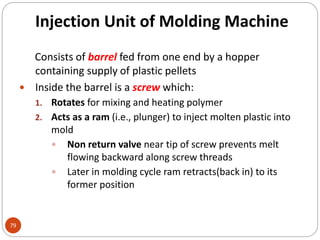

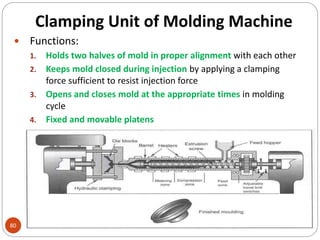

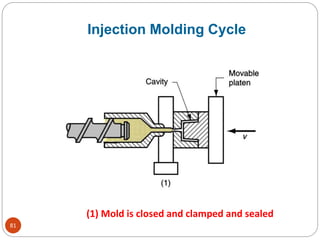

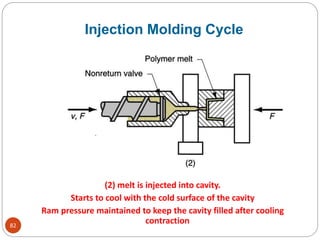

This document provides information about shaping processes for plastics. It discusses various plastic shaping processes including extrusion, injection molding, blow molding, and thermoforming. Specifically, it focuses on extrusion, describing the key components of an extruder including the barrel and screw. It explains how viscosity, temperature, and viscoelasticity impact the extrusion process and discusses die configurations and defects that can occur during extrusion like die swell, sharkskin, and bambooing. It also summarizes processes for producing plastic sheet, film, and hollow profiles by extrusion.