The document discusses extrusion principles and components used in extruding thermoplastics into various products. It contains the following key points:

- Extrusion is a continuous process where thermoplastics are melted and shaped using a screw and die. Common products made via extrusion include films, pipes, sheets, fibers and filaments.

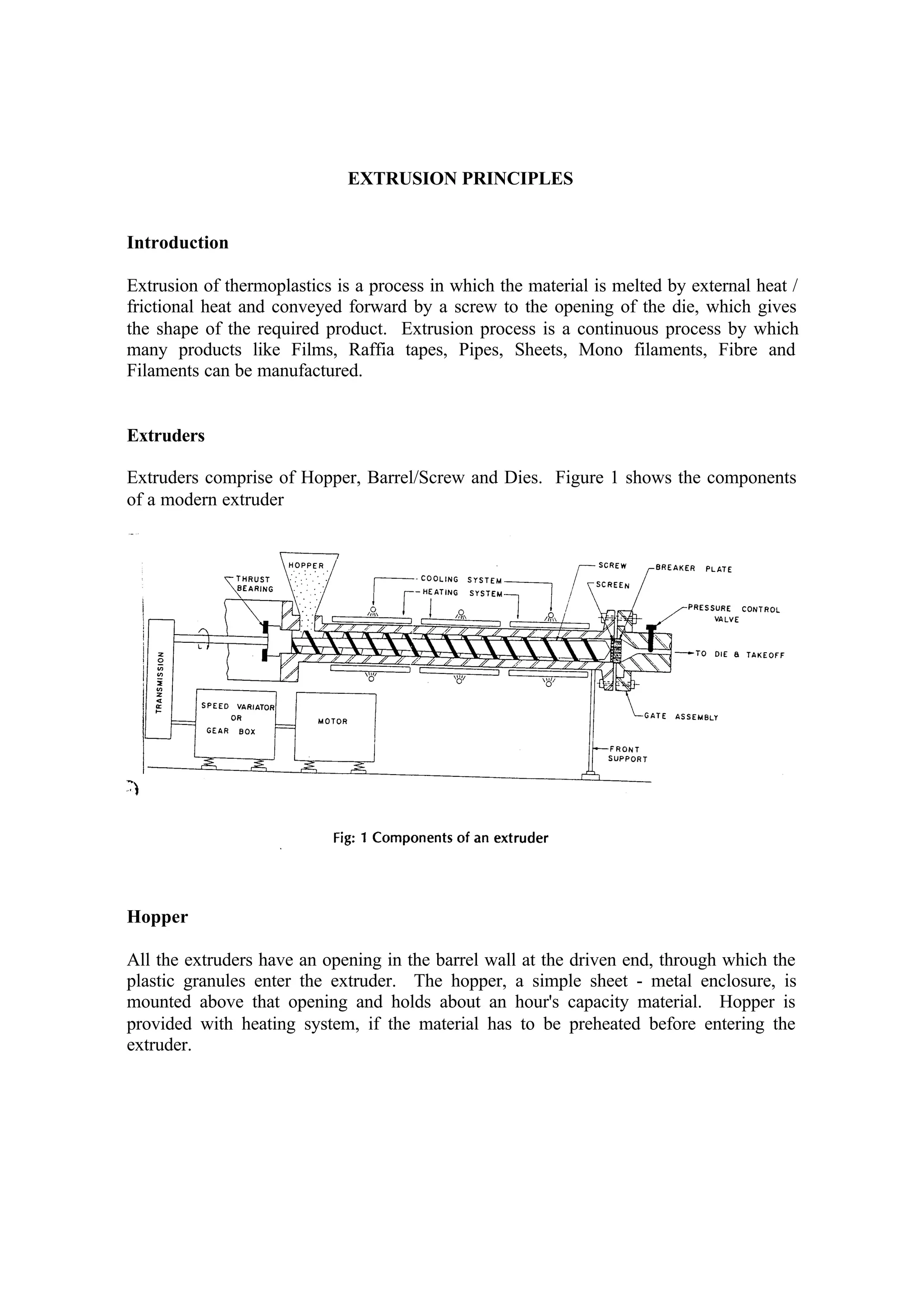

- The main components of an extruder are the hopper, barrel/screw, and die. The hopper feeds plastic granules into the barrel. The screw conveys the melted plastic to the die, which shapes the final product.

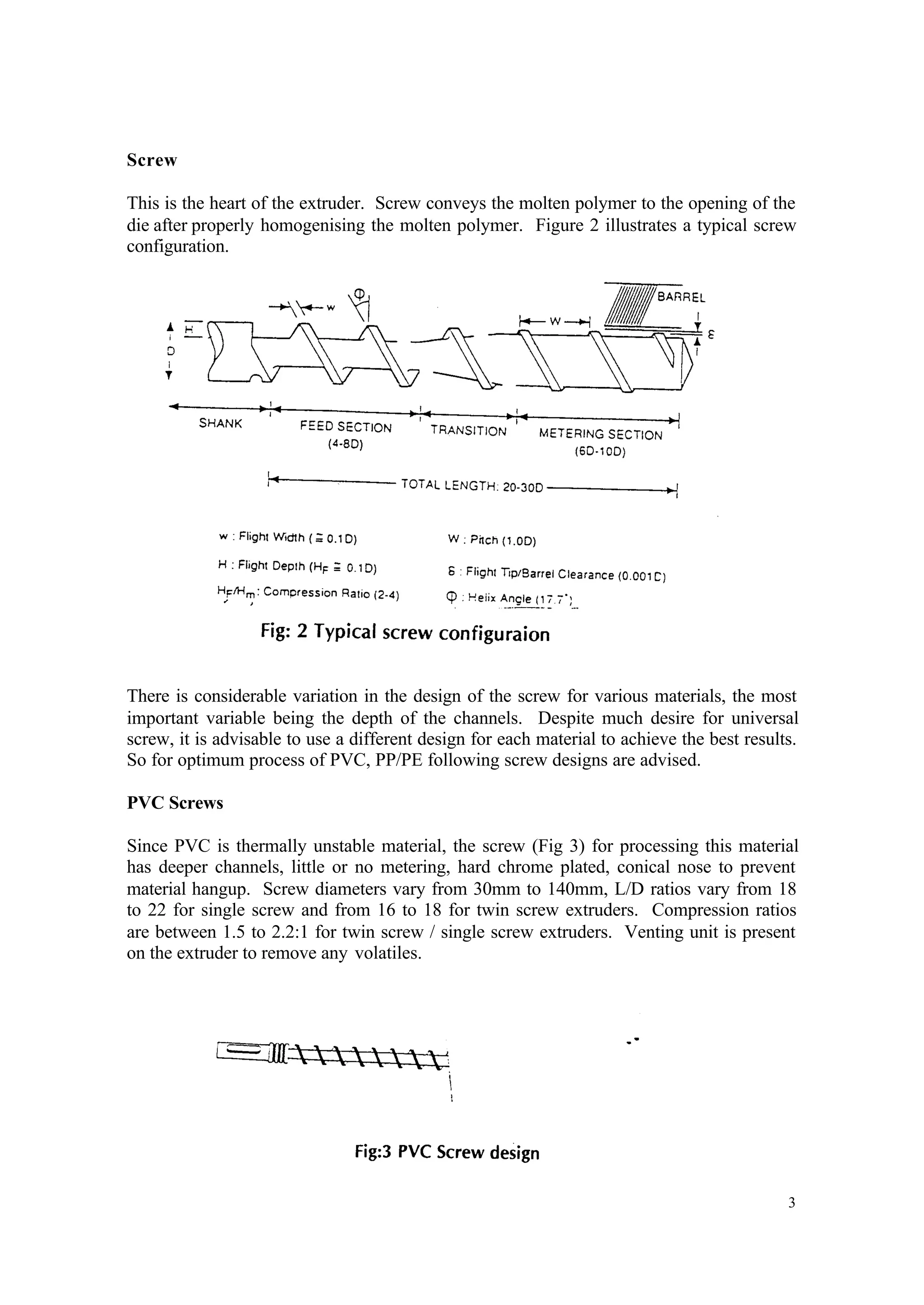

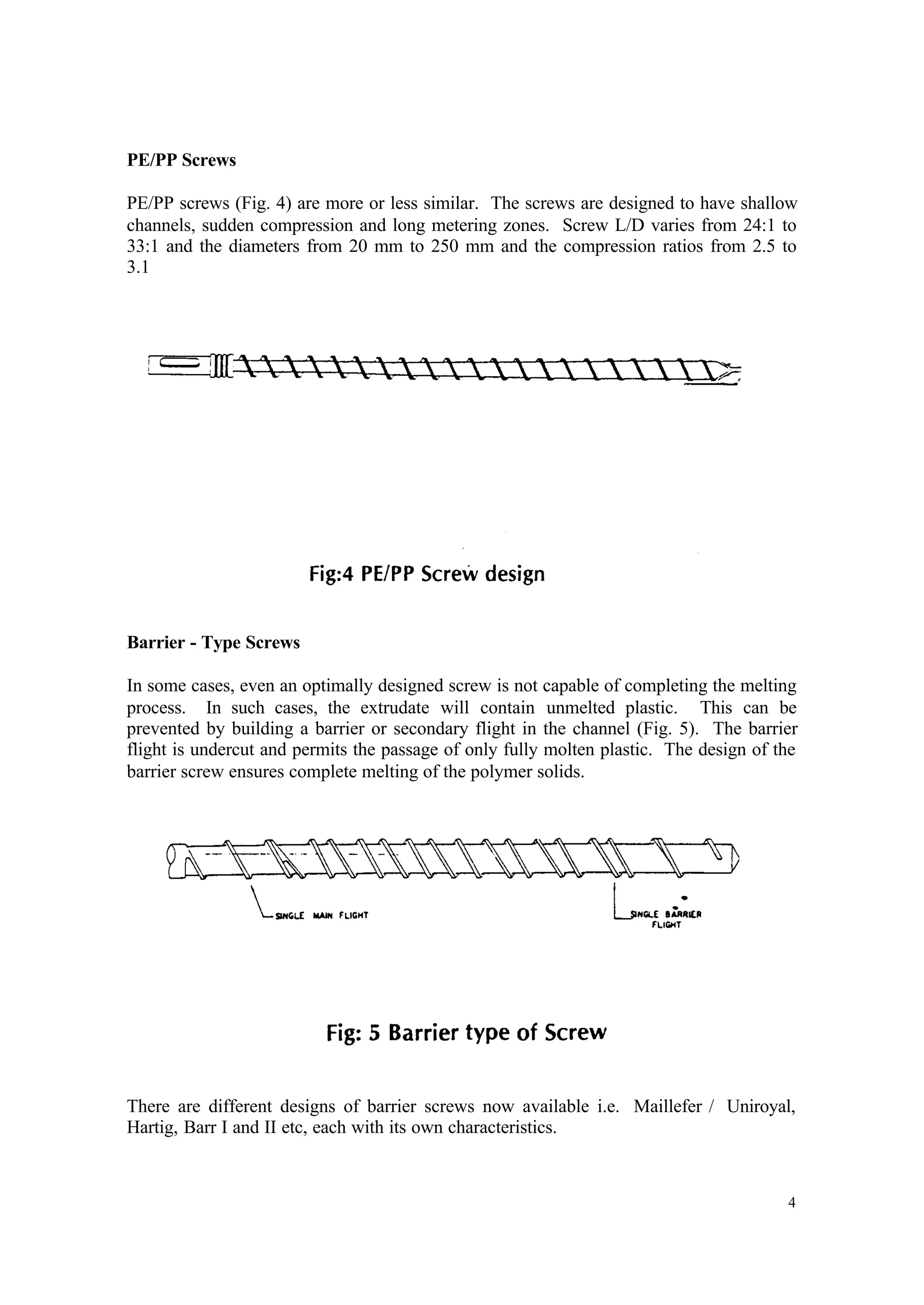

- Screw design depends on the material, with PVC screws having deeper channels to prevent thermal degradation, and PE/PP