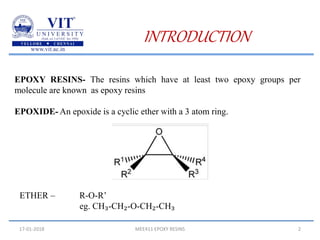

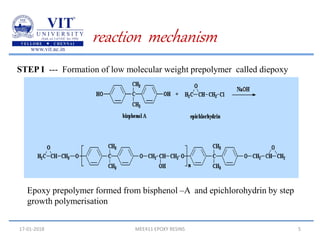

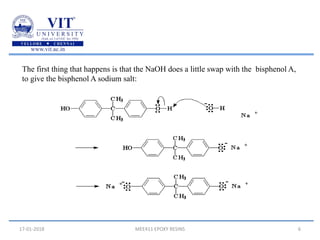

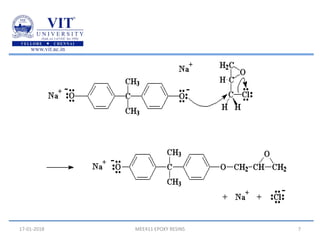

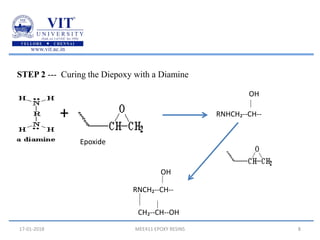

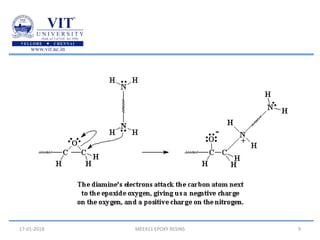

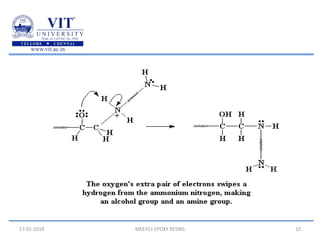

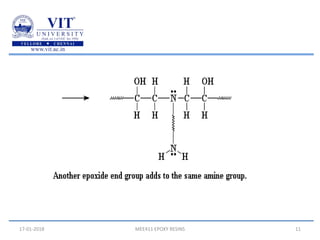

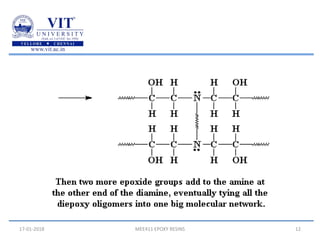

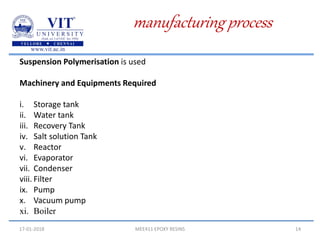

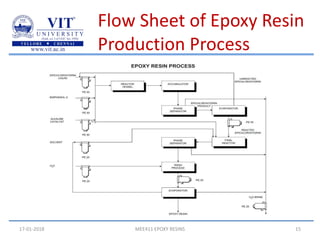

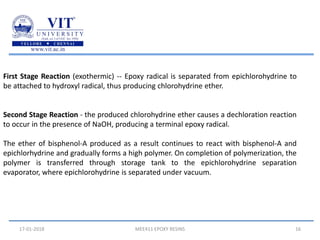

The document provides an overview of epoxy resins, including their types, raw materials, and the chemical reactions involved in their production. It outlines the manufacturing process, essential properties, and various applications across industries. Additionally, it lists notable epoxy resin manufacturers in India and includes commercial names of specific epoxy products.