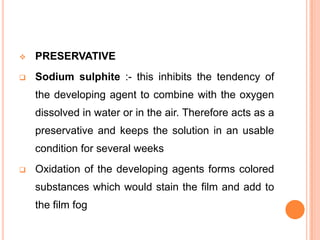

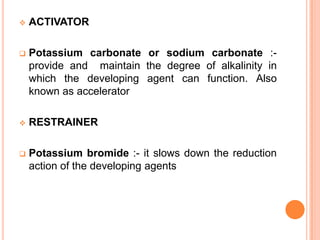

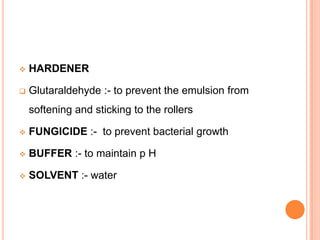

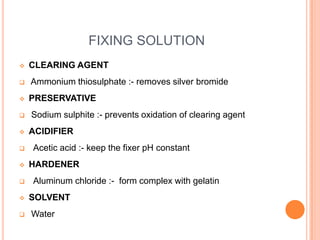

This document provides information on the processing of dental radiographs, including definitions of key terms, the formation of latent images, film processing solutions and procedures, darkroom requirements, and various processing methods. It describes how exposure to radiation results in chemical changes in the film's silver halide crystals to form a latent image, which is then made visible through development and fixing solutions. The roles of developer solutions, fixing solutions, and processing equipment are summarized.