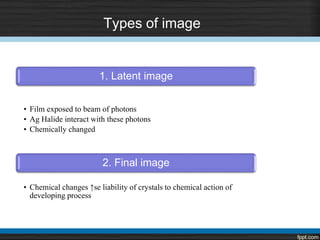

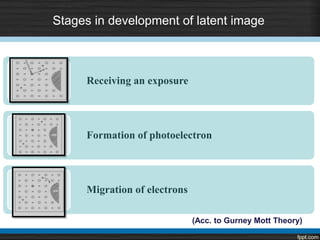

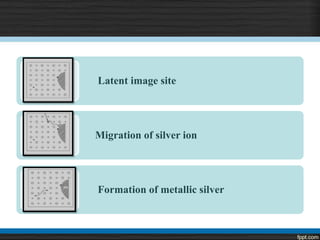

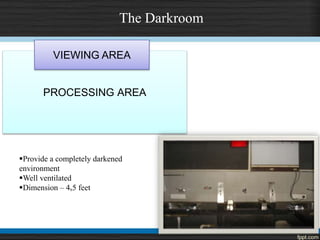

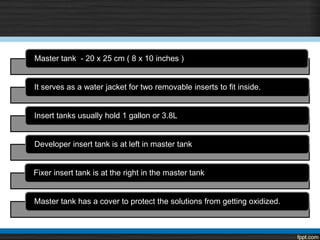

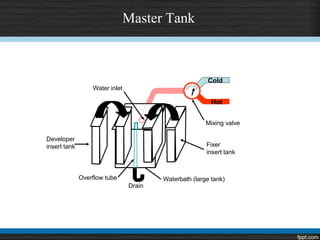

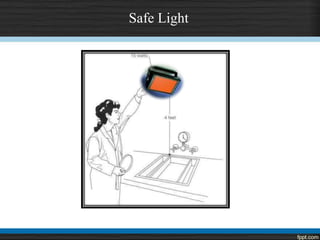

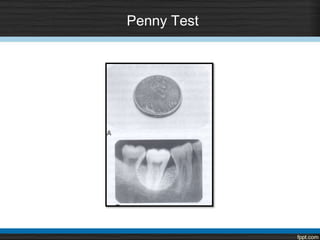

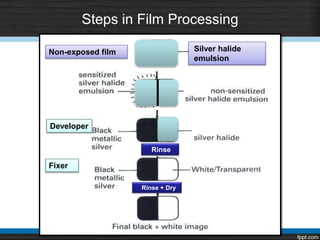

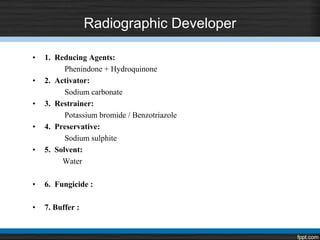

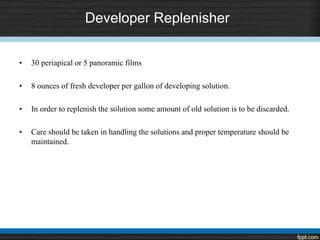

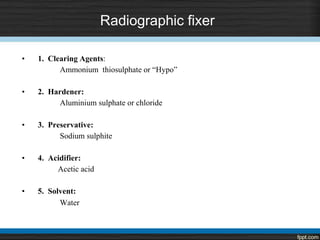

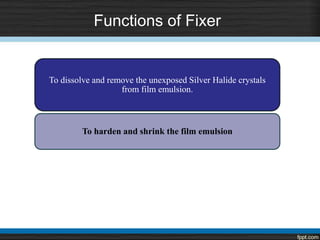

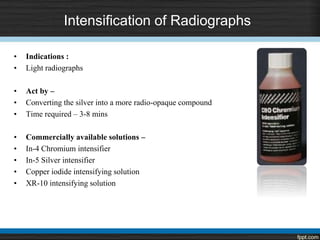

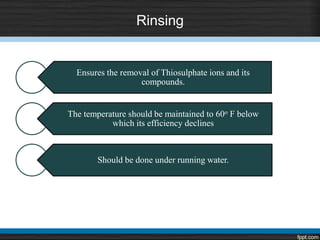

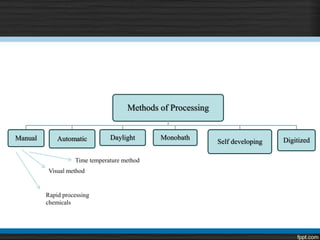

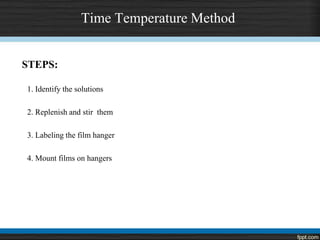

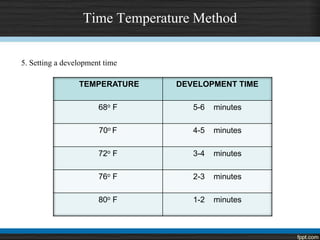

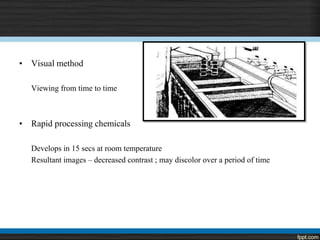

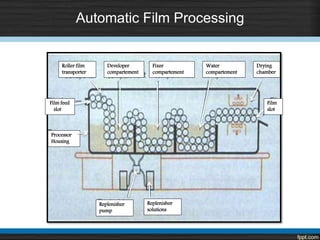

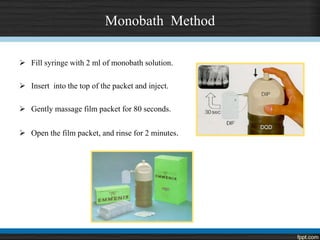

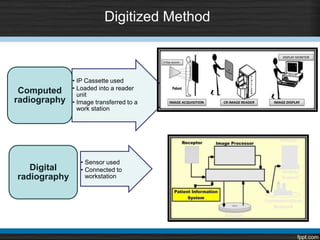

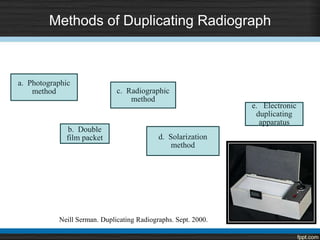

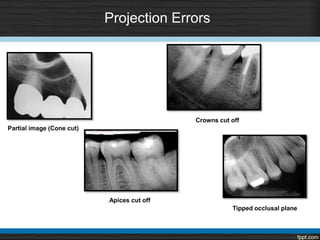

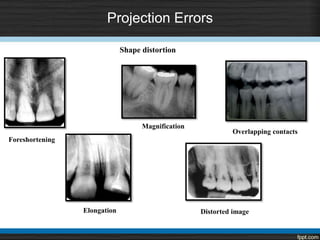

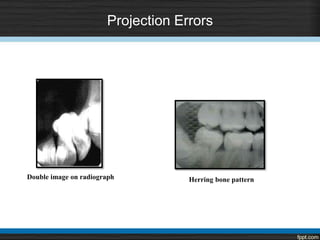

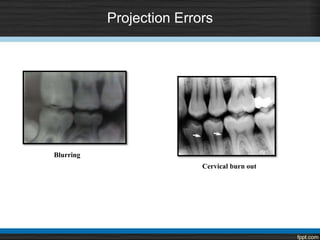

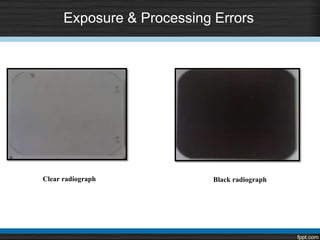

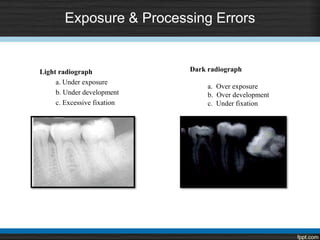

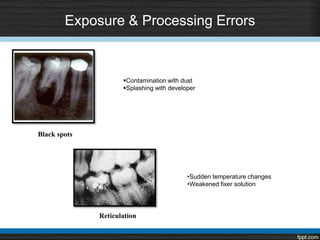

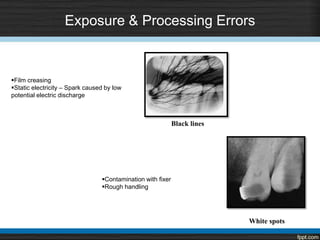

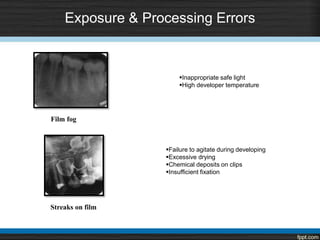

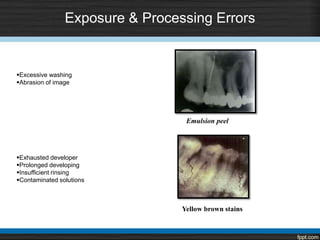

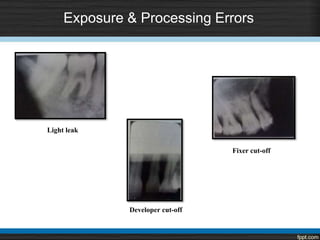

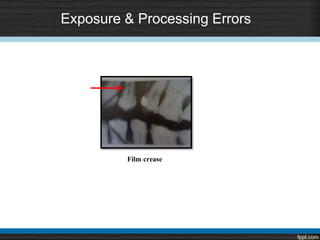

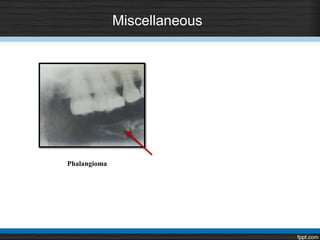

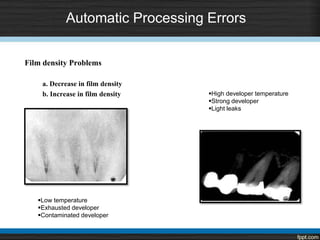

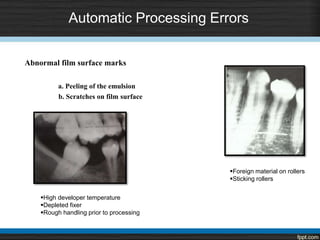

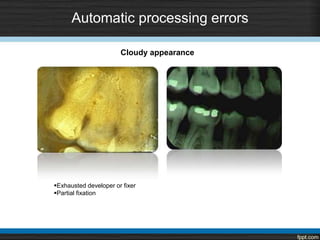

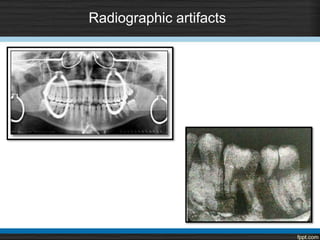

The document discusses intraoral radiographic processing and associated faults, detailing the types of images formed, darkroom requirements, and the processing techniques involved. It emphasizes the importance of proper handling of chemical solutions, processing parameters, and error identification in achieving high-quality diagnostic radiographs. Various processing methods, including manual, automatic, and digitized approaches, are reviewed along with common radiographic faults and their causes.