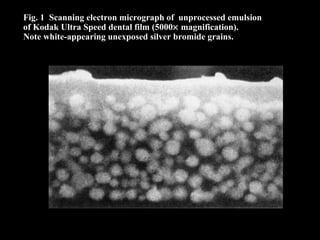

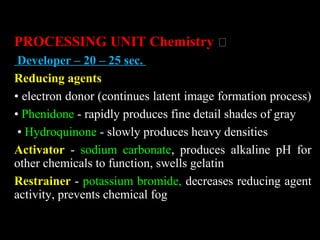

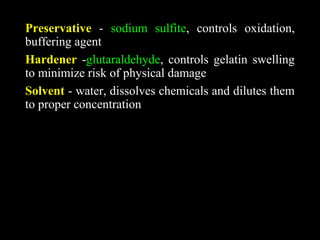

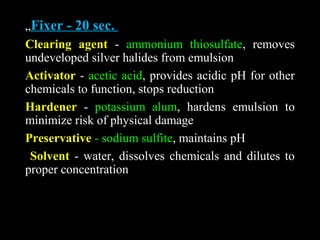

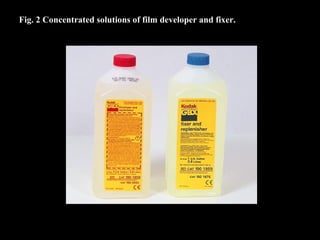

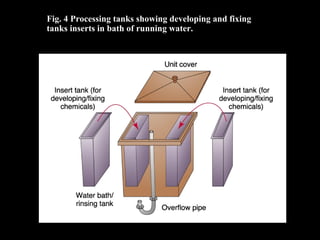

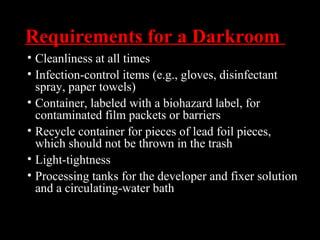

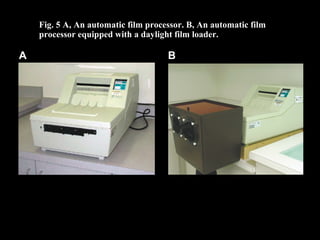

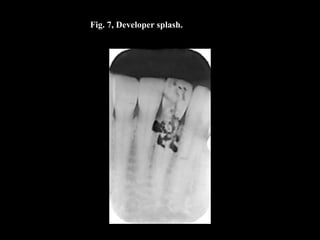

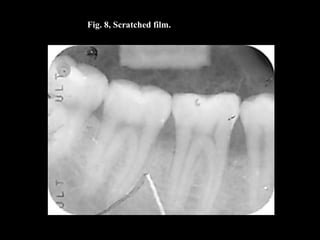

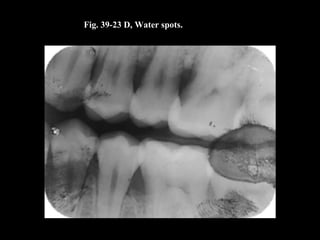

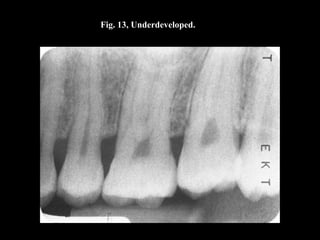

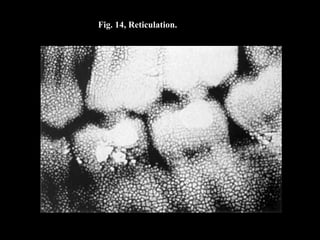

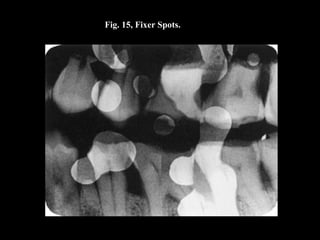

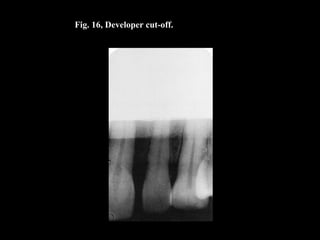

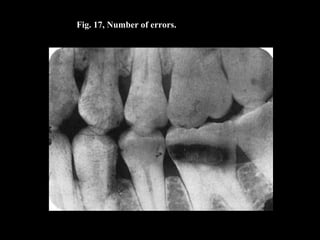

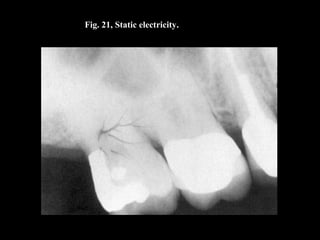

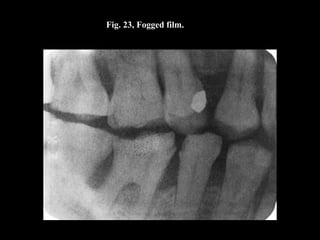

This document discusses proper processing of dental radiographs. It describes the five steps in processing - development, rinsing, fixing, washing, and drying. Developing uses a chemical developer to reduce silver halide crystals to silver, while fixing removes unexposed crystals. Automatic processors maintain time and temperature, but proper maintenance is required to avoid errors like over- or underdevelopment, chemical contamination, scratches, or light exposure. Understanding processing is important to produce diagnostic radiographs and avoid unnecessary radiation exposure from retakes.