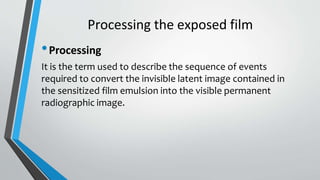

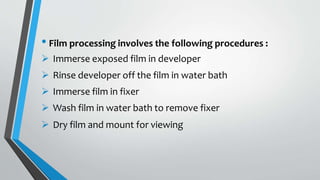

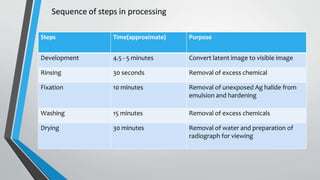

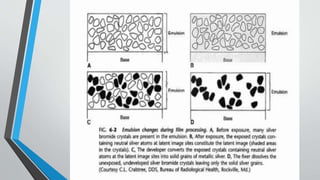

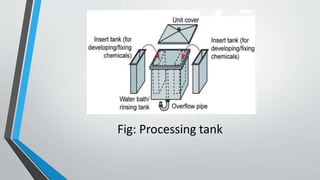

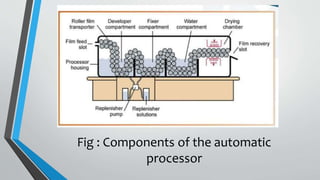

The document discusses the process of developing x-ray film from exposure to the final radiographic image. It involves the following key steps: exposing the film, developing the latent image in developer solution, rinsing, fixing the image in fixer solution, washing, and drying. Proper equipment is needed like processing tanks, thermometers, timers, and a darkroom. Both manual and automatic methods are described. Automatic processing is faster but manual processing allows more control over time and temperature variables. Proper handling and disposal of chemical wastes is also important.