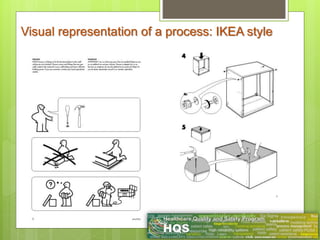

This document provides an overview of process mapping as a quality improvement tool. It discusses how process maps can create a common understanding of a process, identify parts to measure, and help generate hypotheses for change. The document outlines steps for gathering data to understand a problem and create a process map, including observing the process, interviewing staff, and getting stakeholder feedback. It reviews types of process map symbols and provides examples of simple and more complex process maps. Tips are offered on developing process maps, such as beginning with a goal statement, mapping the current not ideal process, and keeping maps simple. An exercise is described where groups map the process of assembling a puzzle and compare their maps to an expert-created ideal map.