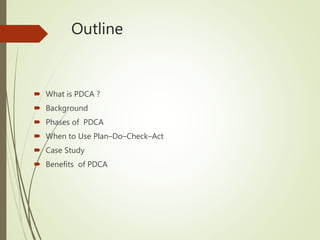

The document discusses the Plan-Do-Check-Act (PDCA) model for continuous improvement. PDCA is an iterative four-step management method used to control and continuously improve processes and products. The four steps are: plan proposed improvements, do implement the plan, check analyze the results, and act determine what modifications should be made to the process based on the results. The document provides an overview of each step and gives an example of how PDCA was used by a leather goods supplier to reduce defects in the production preparation section from 0.4% to 0.2%.

![What is PDCA?

PDCA stands for Plan-Do-Check-Act [1]

Iterative four-stage model for continuous improvement (CI)

It teaches organizations to

• PLAN an action

• DO it

• CHECK it

• ACT on it

[1].http://whatis.techtarget.com/definition/PDCA-plan-do-check-act](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-3-320.jpg)

![What is PDCA?[1]

Implementing New Ideas in a Controlled Way

It is also known as

• plan–do–check–adjust

• Deming circle/cycle/wheel

• Shewhart cycle, control circle/cycle

• or plan–do–study–act (PDSA)

[1].http://whatis.techtarget.com/definition/PDCA-plan-do-check-act](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-4-320.jpg)

![Background

Walter Shewhart (1920’s)

Shewhart Learning and

Improvement cycle [2]

W. Edwards Deming (1950’s)

[2]

It is a combination of

management thinking with

statistical analysis

Japanese translation into

English became PDCA.

[3]https://www.isixsigma.com/dictionary/deming-cycle-pdca/

[2]https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2464836/](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-5-320.jpg)

![PDCA – Overview

Plan

Do

Check

AchievedNo

Modify

parameters

goal?

Yes

Act

Another problem

or improvement

[1].http://whatis.techtarget.com/definition/PDCA-plan-do-check-act](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-6-320.jpg)

![Four Phases of PDCA [5]

Plan a change aimed at improvement

Do – Carry out the change

Check/Study the results

Act - Adopt, adapt, or abandon

[5]www.yourarticlelibrary.com/business/continuous-business-process...4-phases/21128/](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-7-320.jpg)

![PLAN

Analyze current condition

Identify exactly what your problem is

Map the process

Establish the objectives

[5]www.yourarticlelibrary.com/business/continuous-business-process...4-phases/21128/](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-8-320.jpg)

![DO

Implement the plan

Generate possible solutions

execute the process

make the product.

Collect data for charting and analysis in the following "CHECK" and

"ACT" steps.

[5]www.yourarticlelibrary.com/business/continuous-business-process...4-phases/21128/](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-9-320.jpg)

![Check/Study

Study the actual results (measured and collected in "DO"

above)

Compare

Against the expected results

[5]www.yourarticlelibrary.com/business/continuous-business-process...4-phases/21128/](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-10-320.jpg)

![Act

Take action based on what you learned in the study step

Two Possibilities

1. If the change did not work, go through the cycle again

with a different plan.

2. If you were successful then standardize.

[5]www.yourarticlelibrary.com/business/continuous-business-process...4-phases/21128/](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-11-320.jpg)

![ As a model for continuous improvement.

When starting a new improvement project.

When developing a new or improved design of a process,

product or service.

Exploring a range of possible new solutions to problems

When to Use Plan–Do–Check–Act?[7]

[7]http://asq.org/learn-about-quality/project-planning-tools/overview/pdca-cycle.html](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-12-320.jpg)

![ When defining a repetitive work process.

When planning data collection and analysis in order to

verify and prioritize problems or root causes.

When implementing any change.

Avoiding the large scale wastage of resources that comes

with full scale implementation of poor solution.

When to Use Plan–Do–Check–

Act?

[7]http://asq.org/learn-about-quality/project-planning-tools/overview/pdca-cycle.html](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-13-320.jpg)

![A Case Study

Maroco (Supplier of: Leather Goods,

leather items )

About Company

• Production unit under study

• Located in northern Portugal,

• Famous on the Production of leather components for

leather goods

[8]Fábio A. Fernandes, Sérgio D. Sousa, Member, IAENG and Isabel Lopes , “On the Use of Quality Tools: A Case

Study ”, Journal of World Congress on Engineering July 3-5, 2013.](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-14-320.jpg)

![Quality Management

Methodology

Three Stages of Quality Management

• Assessment of quality management processes

• General quality data analysis

• The application PDCA cycle (to solve a specific problem that was

considered a priority in the previous step

[8]Fábio A. Fernandes, Sérgio D. Sousa, Member, IAENG and Isabel Lopes , “On the Use of Quality Tools: A Case

Study ”, Journal of World Congress on Engineering July 3-5, 2013.](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-15-320.jpg)

![Production system of Functional

Sections

It is organized into three functional sections

• cutting (raw material (leather) is cut giving rise to various

components);

• preparation (components undergo various operations,

including, uniformity and reduction of leather thickness,

pressing, bonding, molding and painting);

• assembly (components are assembled to form the end

product, through sewing operations).

[8]Fábio A. Fernandes, Sérgio D. Sousa, Member, IAENG and Isabel Lopes , “On the Use of Quality Tools: A Case

Study ”, Journal of World Congress on Engineering July 3-5, 2013.](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-16-320.jpg)

![Plan

In Plan phase causes of the problem were analyzed and an

action plan was established

The problem identified in preparation section, it was related to

the nonconforming components e.g. thinning of the leather, that

were detected in process and which led to several complaints

from customers.

• The thickness of the component is outside the specification limits of

0.40 ± 0.05 mm;

[8]Fábio A. Fernandes, Sérgio D. Sousa, Member, IAENG and Isabel Lopes , “On the Use of Quality Tools: A Case

Study ”, Journal of World Congress on Engineering July 3-5, 2013.](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-18-320.jpg)

![ Brainstorming sessions were performed in regular meetings to

identify the possible causes of the problem and build the action plan.

e.g. Replacement of the measuring instrument, the implementation

of the optimum combination of parameters for the equalization

machine

[8]Fábio A. Fernandes, Sérgio D. Sousa, Member, IAENG and Isabel Lopes , “On the Use of Quality Tools: A Case

Study ”, Journal of World Congress on Engineering July 3-5, 2013.](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-19-320.jpg)

![DO & Check

Do Phase

After formulating the action plan it was necessary to implement it,

by acting on the processes.

Our plan is to increased the machine blades sharpness

Check Phase

After the Plan and Do steps, the Check step was carried out to

evaluate the effectiveness of the actions. E.g. In this case study The

average production of nonconforming components decreased from

about 0.40% to 0.20%.

If we don’t achieve effective result then we again perform the

Improvement process till that we get the effective result

[8]Fábio A. Fernandes, Sérgio D. Sousa, Member, IAENG and Isabel Lopes , “On the Use of Quality Tools: A Case

Study ”, Journal of World Congress on Engineering July 3-5, 2013.](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-20-320.jpg)

![Act

Act Phase

The last step of the PDCA cycle is based on the standardization of the

actions in which effectiveness was observed in the Check step.

Result

[8]Fábio A. Fernandes, Sérgio D. Sousa, Member, IAENG and Isabel Lopes , “On the Use of Quality Tools: A Case

Study ”, Journal of World Congress on Engineering July 3-5, 2013.](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-21-320.jpg)

![References

[3]https://www.isixsigma.com/dictionary/deming-cycle-pdca/

[2]https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2464836/

[1].http://whatis.techtarget.com/definition/PDCA-plan-do-check-act

[4]www.change-management-consultant.com/deming-cycle.html

[5]www.yourarticlelibrary.com/business/continuous-business-

process...4-phases/21128/

[6]www.brighthubpm.com › Methods and Ideologies

[8]Fábio A. Fernandes, Sérgio D. Sousa, Member, IAENG and Isabel

Lopes , “On the Use of Quality Tools: A Case Study ”, Journal of World

Congress on Engineering July 3-5, 2013.

[7]http://asq.org/learn-about-quality/project-planning-

tools/overview/pdca-cycle.html](https://image.slidesharecdn.com/pdcapresentation2-170418191706/85/PDCA-Plan-Do-Check-Act-24-320.jpg)