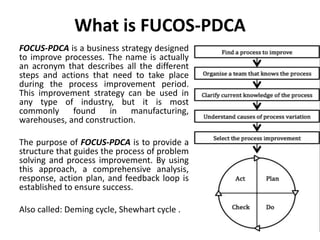

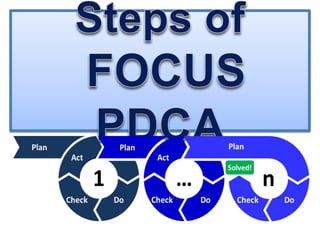

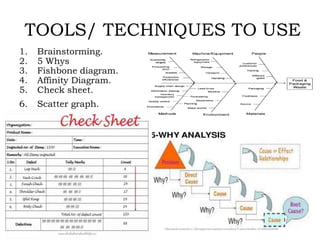

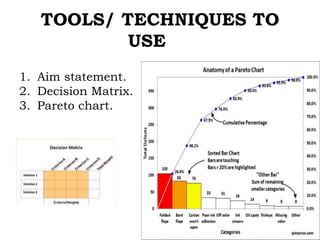

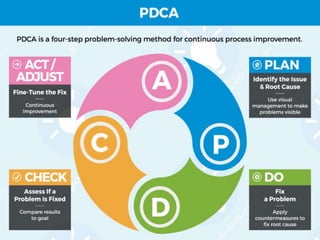

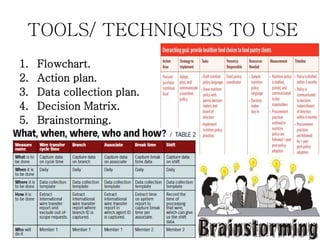

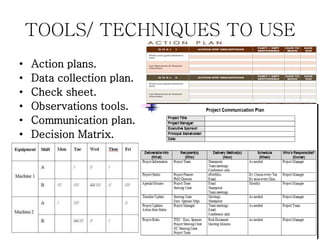

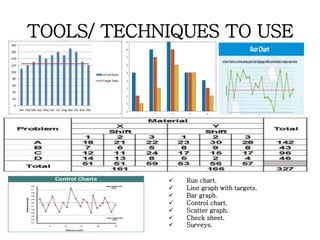

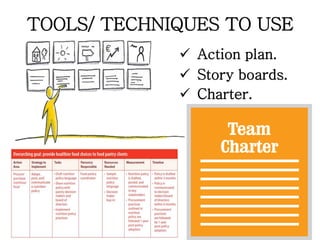

The document outlines the focus-pdca strategy, a process improvement framework applicable across various industries, emphasizing structured steps for analysis, action, and feedback. It details the stages of implementing this methodology, from identifying a process that needs improvement to selecting a strategy, executing the action plan, and evaluating outcomes. The focus-pdca also incorporates tools and techniques for effective problem solving and continuous improvement, guiding teams to align processes with organizational goals.