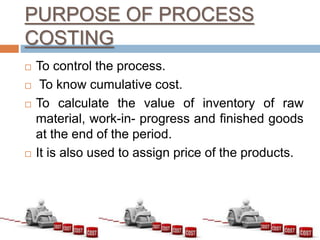

Process costing is a method used by manufacturing industries to calculate the cost of production at each stage of converting raw materials into finished goods. It involves allocating total manufacturing costs to products based on normal production levels. Process costing is used in industries like chemicals, textiles, steel, and sugar that involve sequential production processes with continuous flow of goods. The method determines an average cost per equivalent unit and helps control costs, calculate inventory values, and assign product prices at each stage of multiple processes.