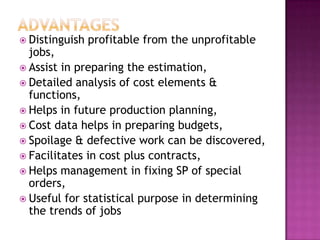

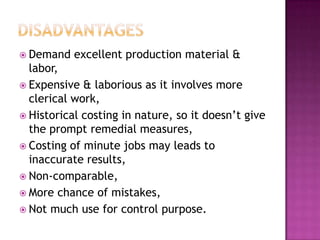

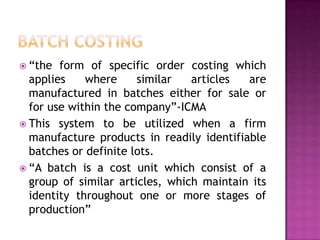

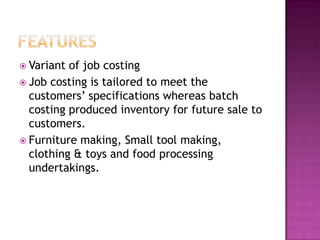

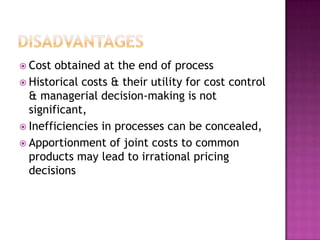

This document discusses different types of costing methods used in manufacturing including job costing, batch costing, contract costing, and process costing. Job costing is used to determine the costs of specific jobs or orders. Batch costing is a variant of job costing where similar products are manufactured in batches. Contract costing is a variant of job costing applied to construction projects. Process costing is used for mass production of standardized goods and tracks costs at each stage of production. The document outlines key features, advantages, and disadvantages of each costing method.