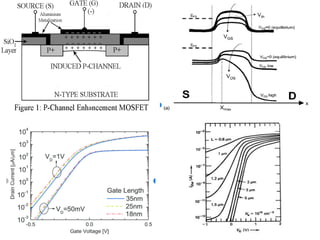

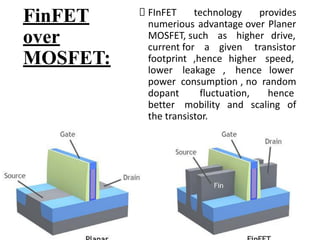

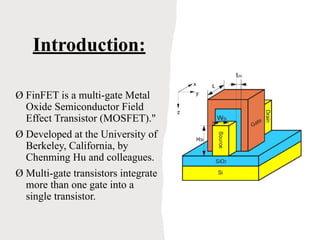

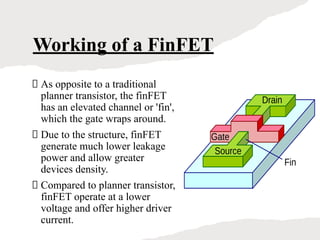

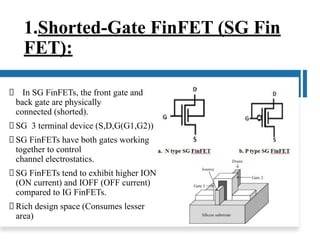

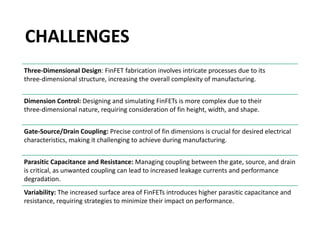

FinFET technology, developed to address the limitations of traditional MOSFETs, employs a three-dimensional structure for improved electrical control, leading to lower power consumption and higher performance in integrated circuits. Applications span across high-performance processors, mobile devices, and automotive electronics, showcasing its significance in modern technology. Despite its advantages, challenges exist in fabrication due to its complex three-dimensional design and sensitivity to dimension control.