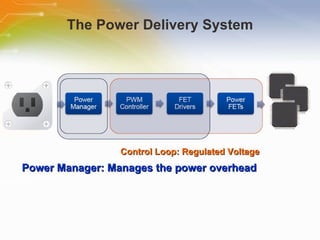

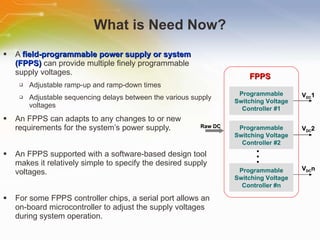

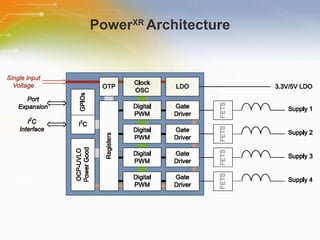

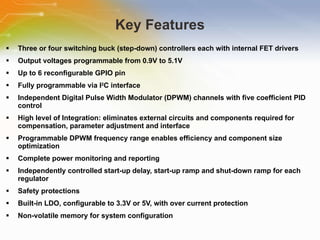

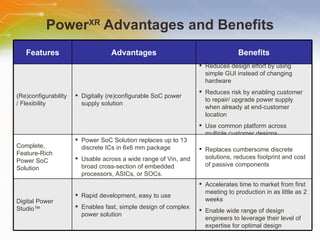

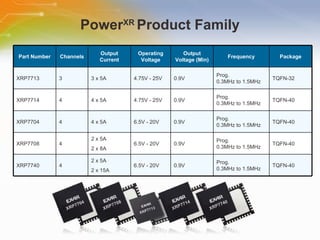

Power XR is a digital power solution chip that can programmably control multiple voltage supplies. It integrates digital power control and analog switches on a single chip. Power XR devices can control power-up, power-down and ramping speeds of voltage supplies independently. Power XR replaces up to 13 discrete components and provides flexible, reconfigurable power supply design.