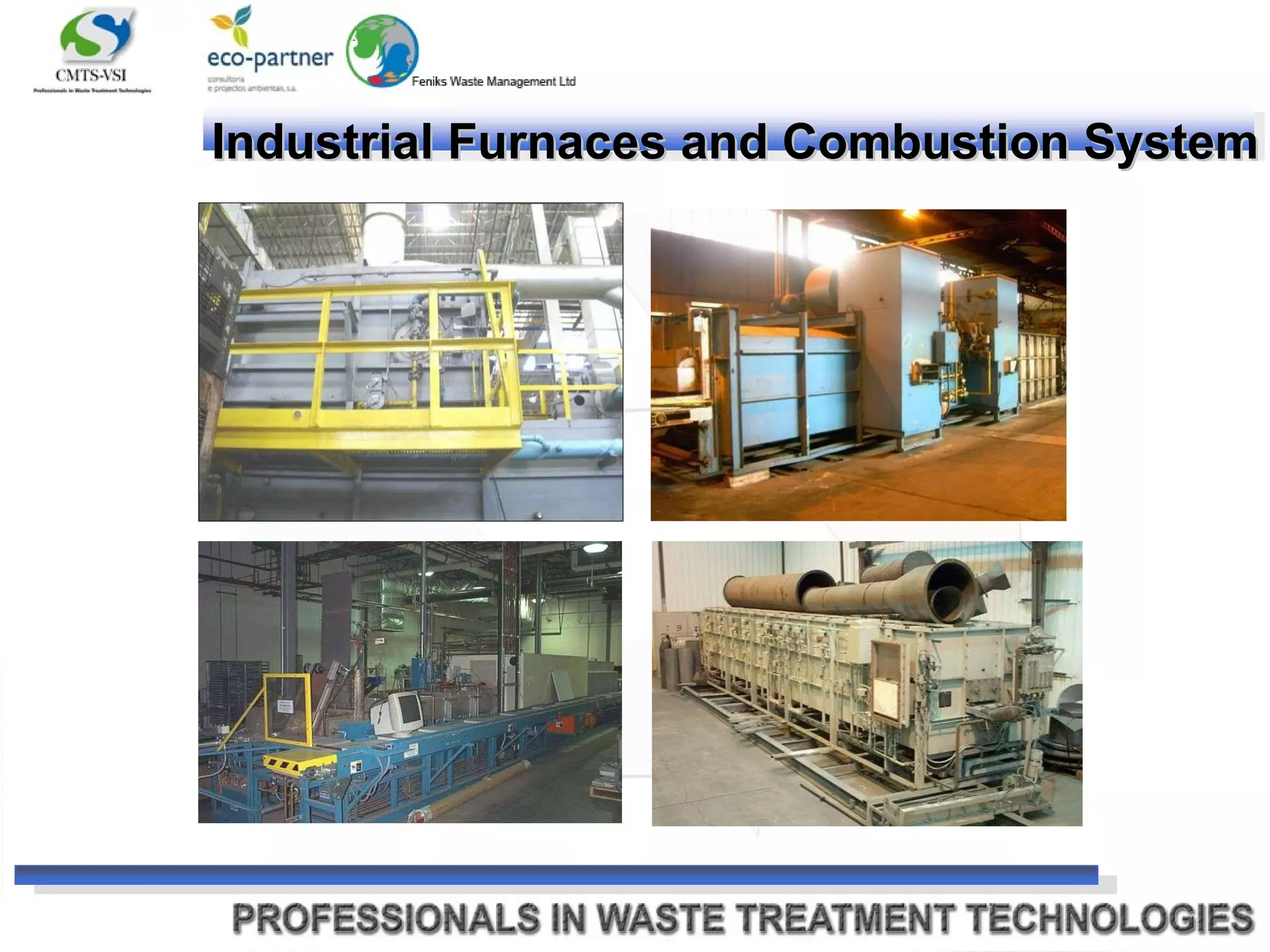

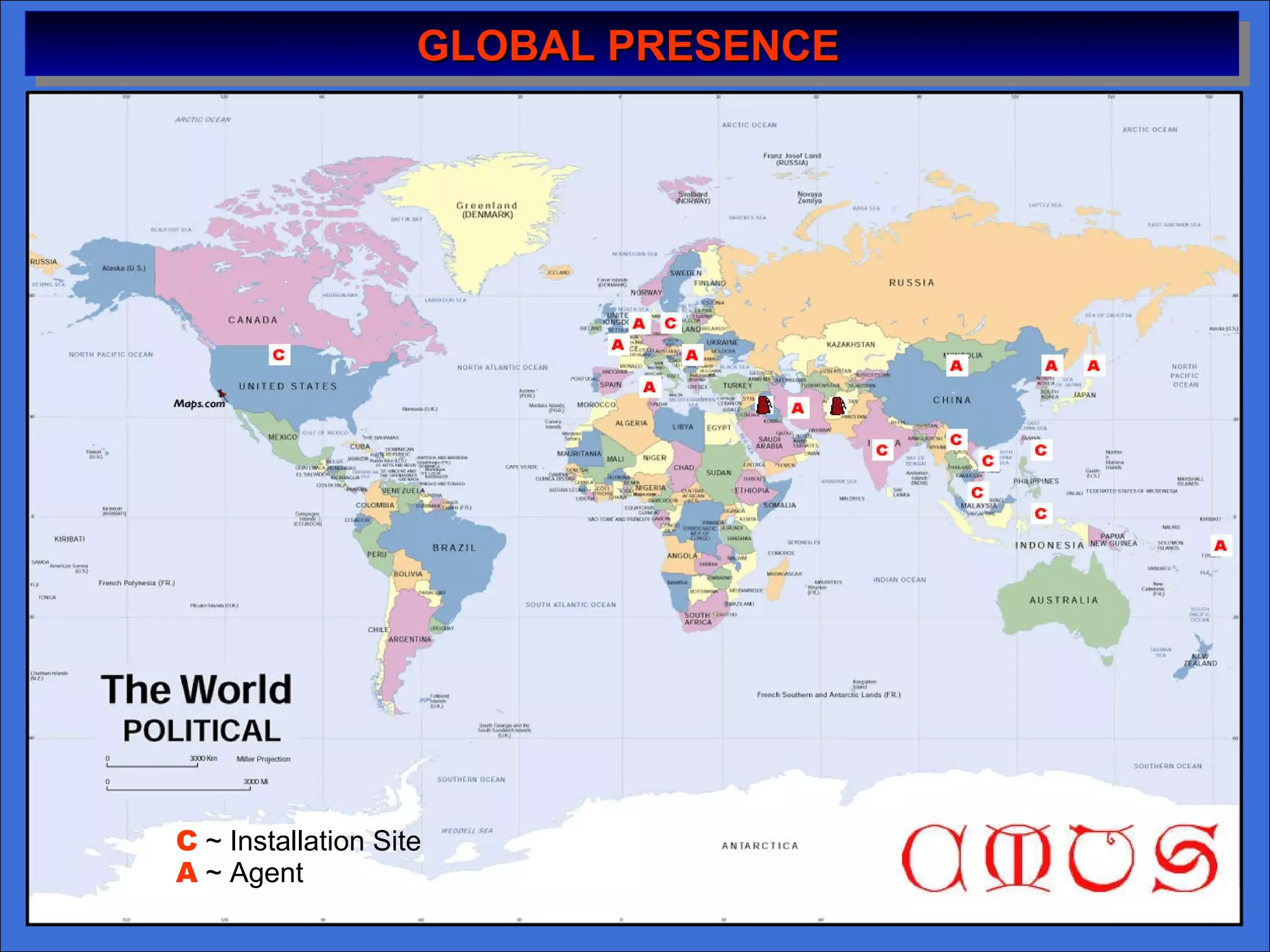

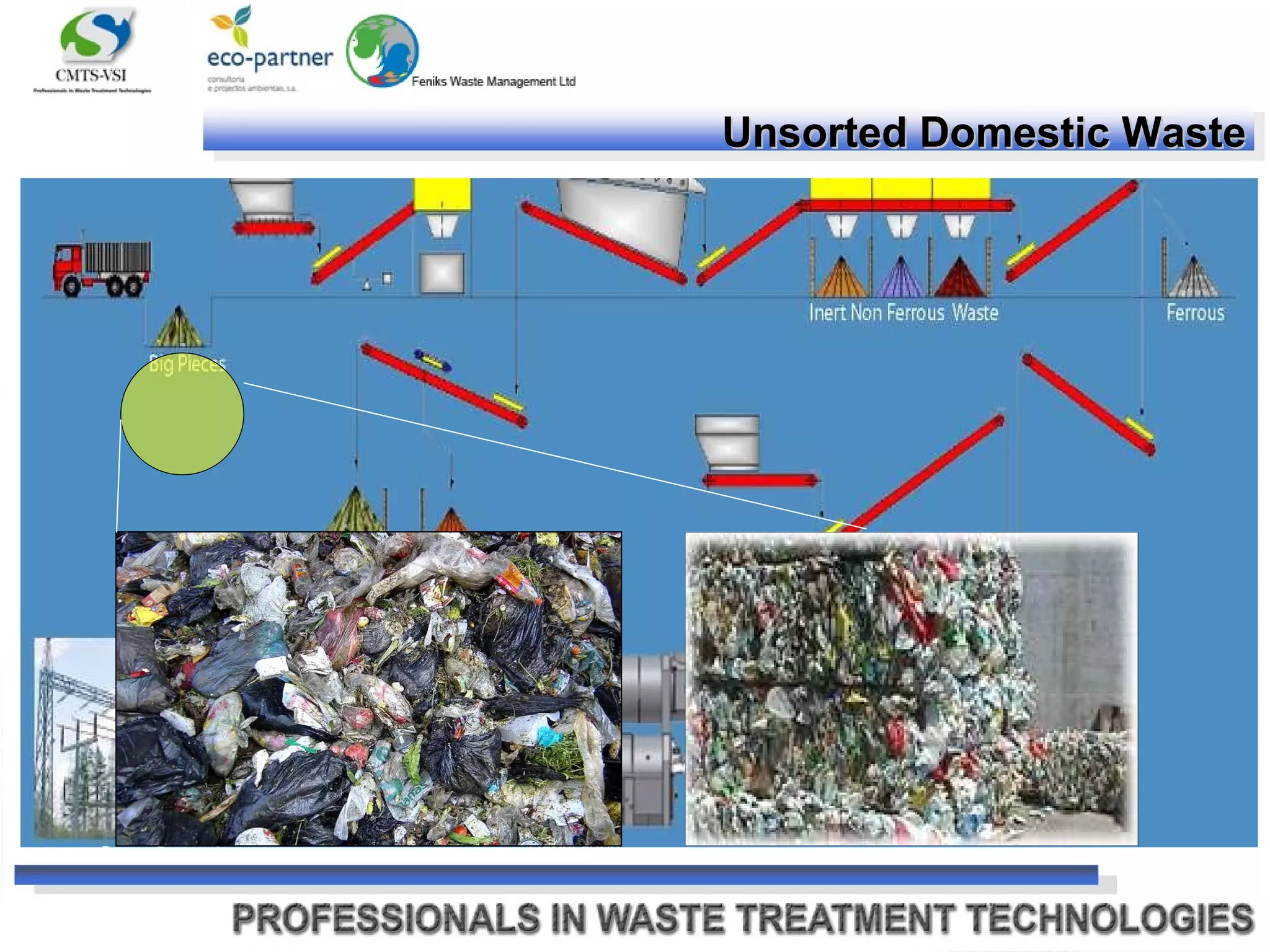

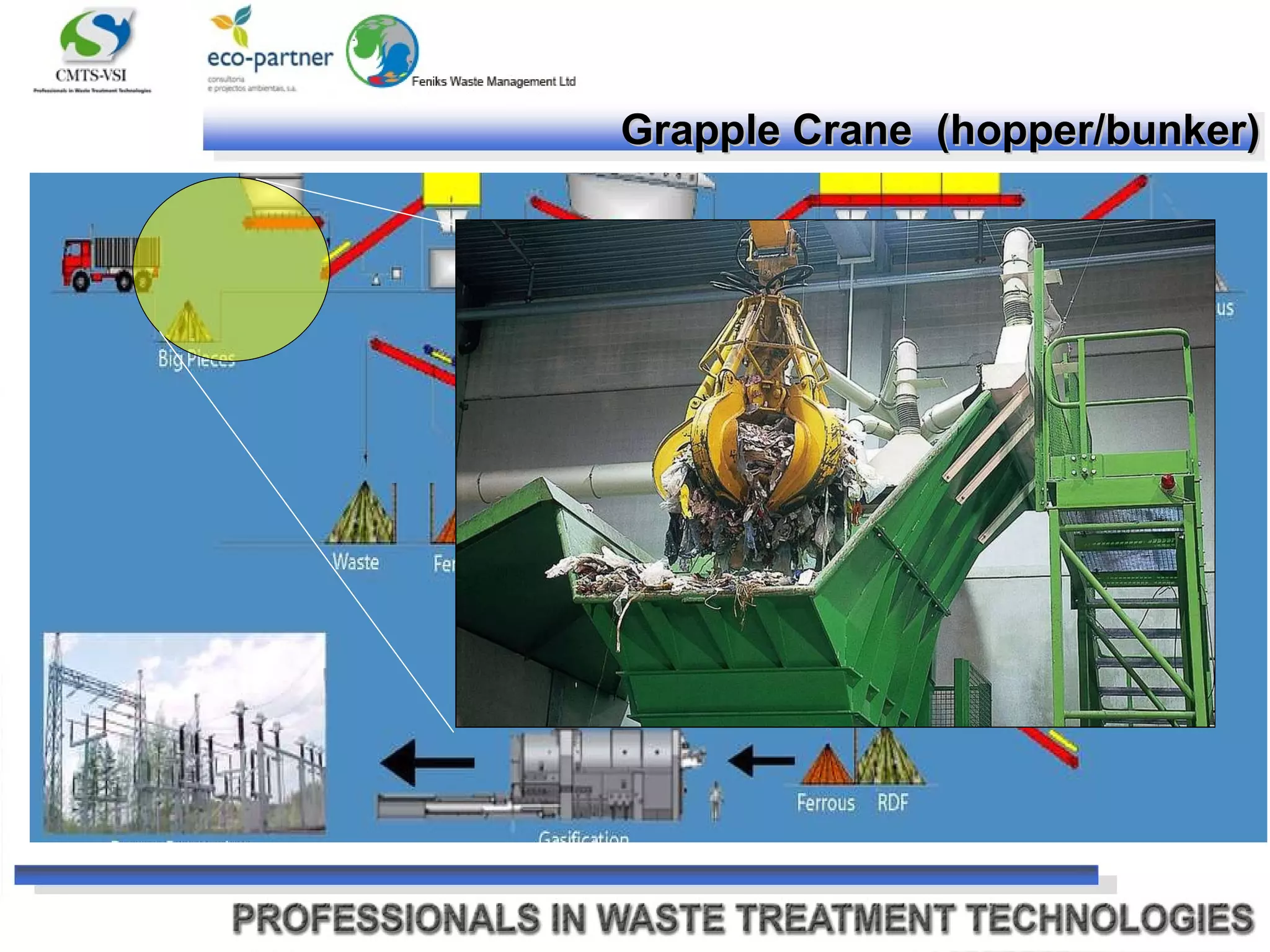

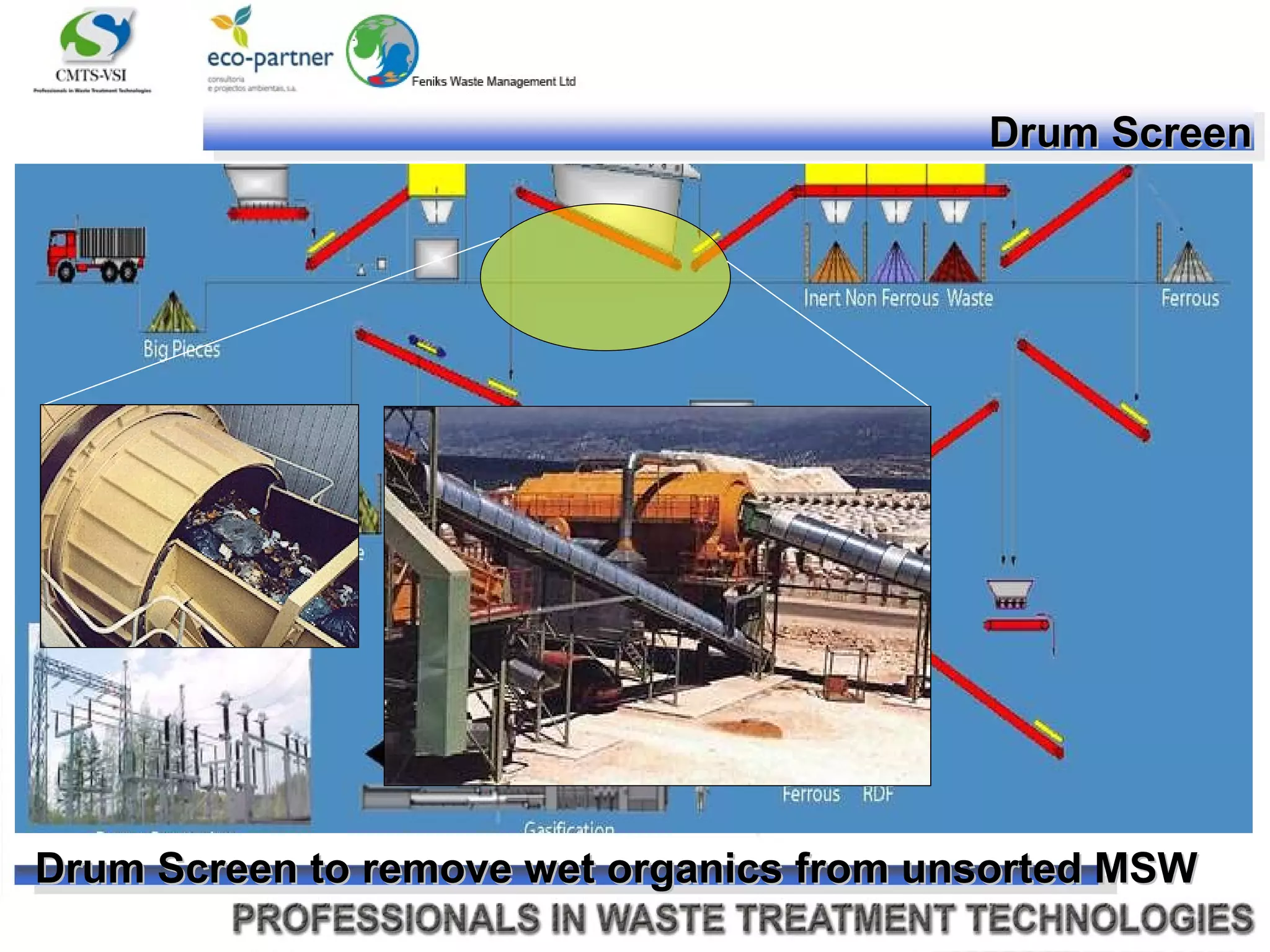

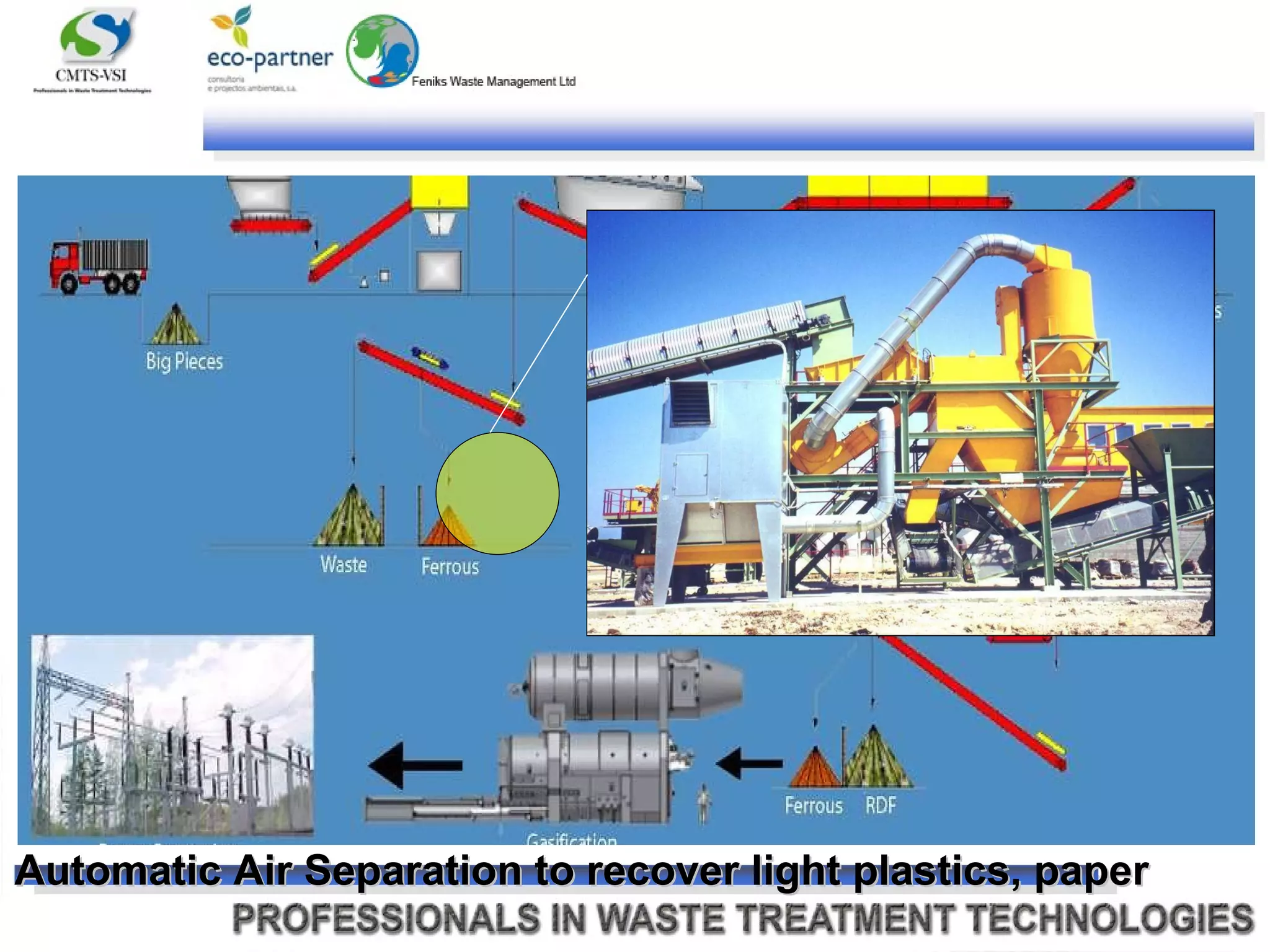

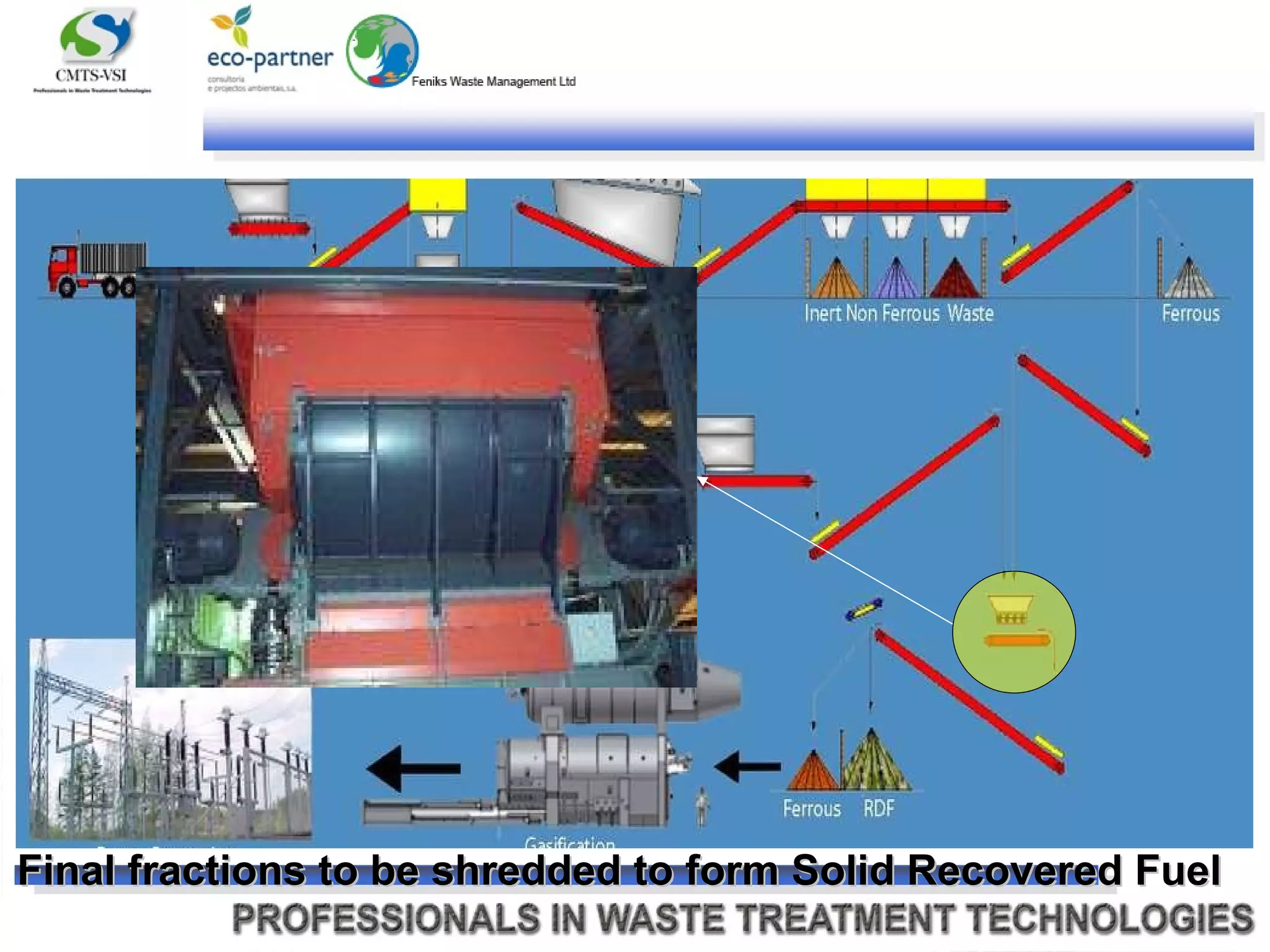

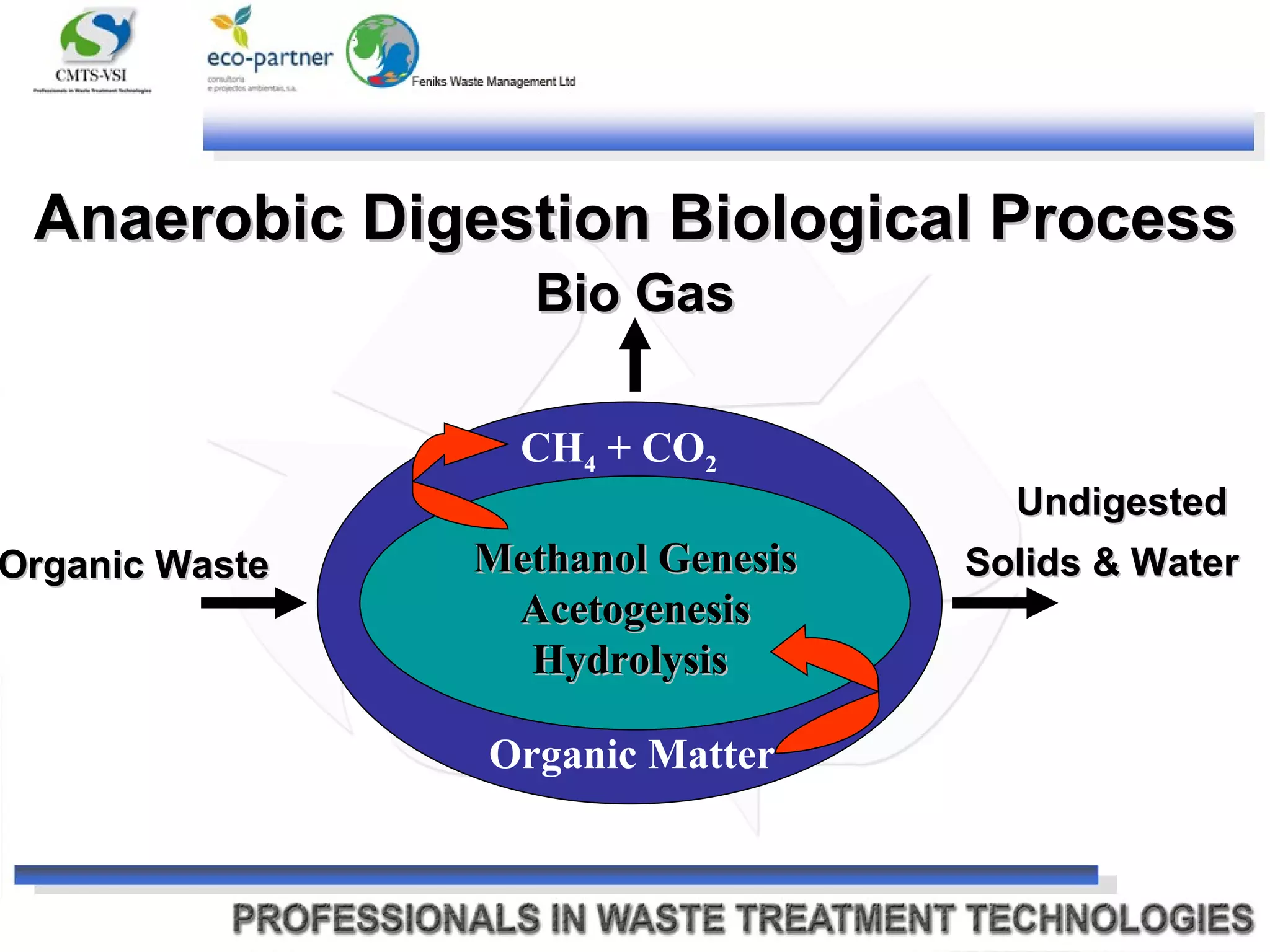

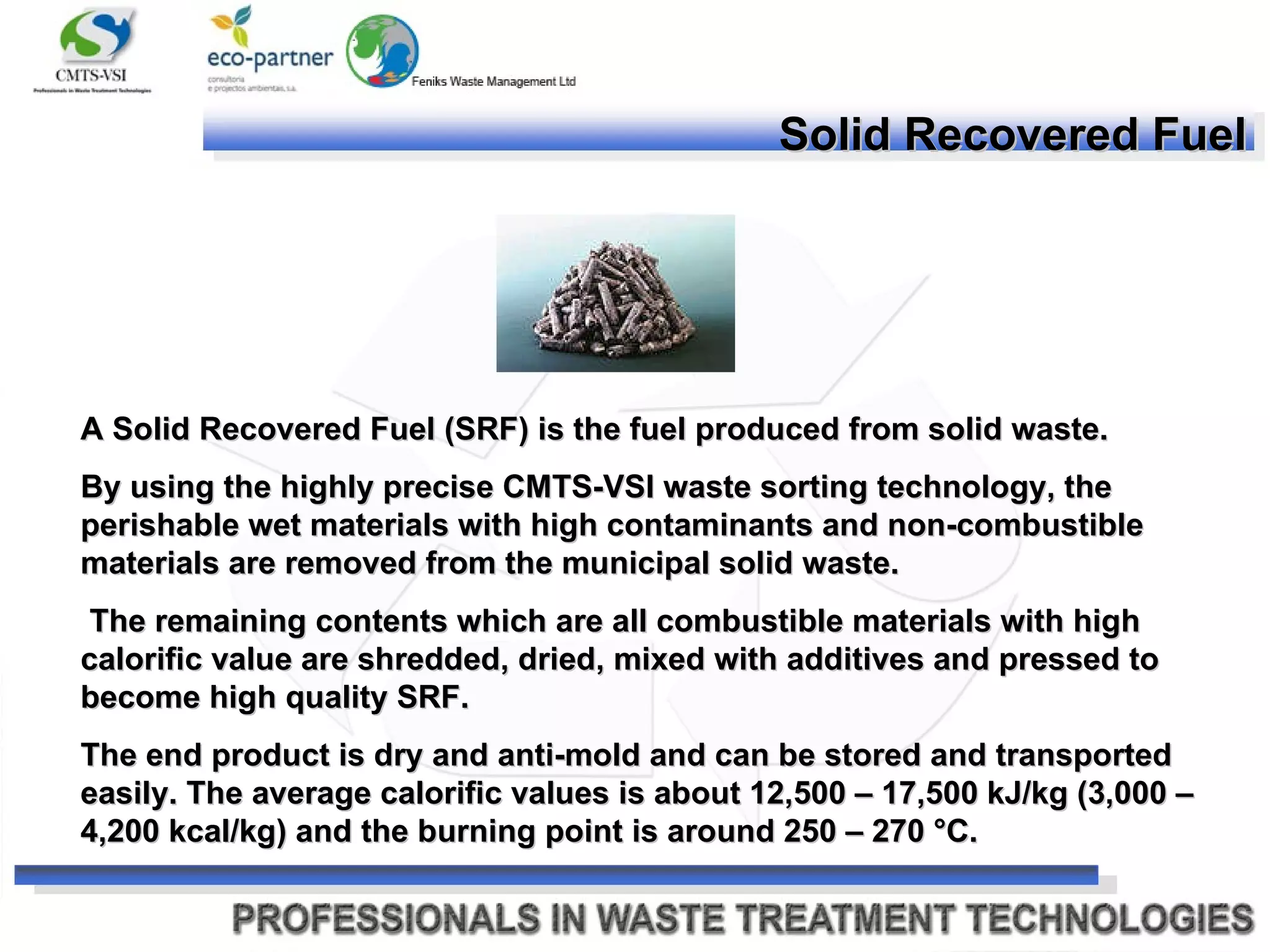

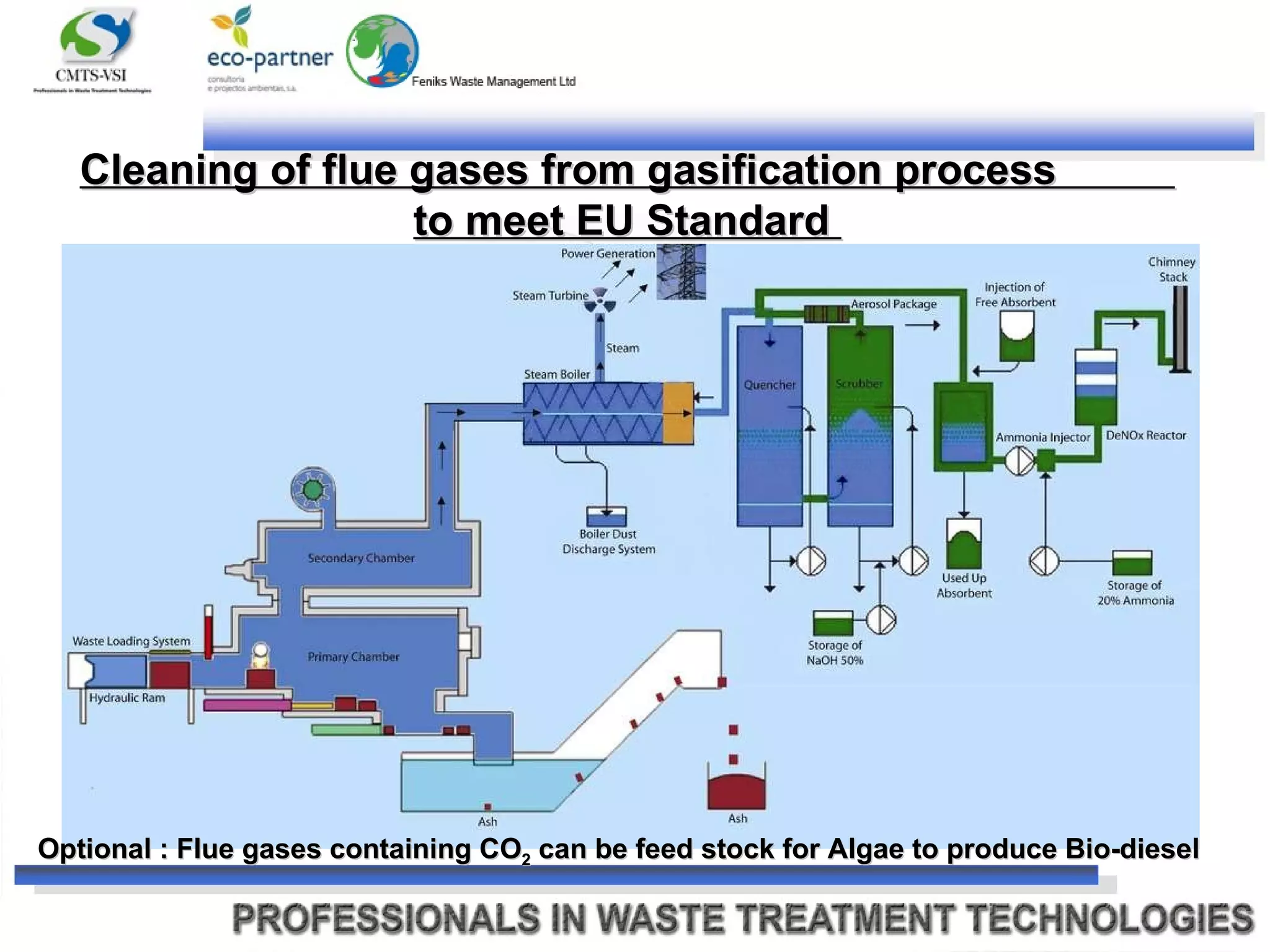

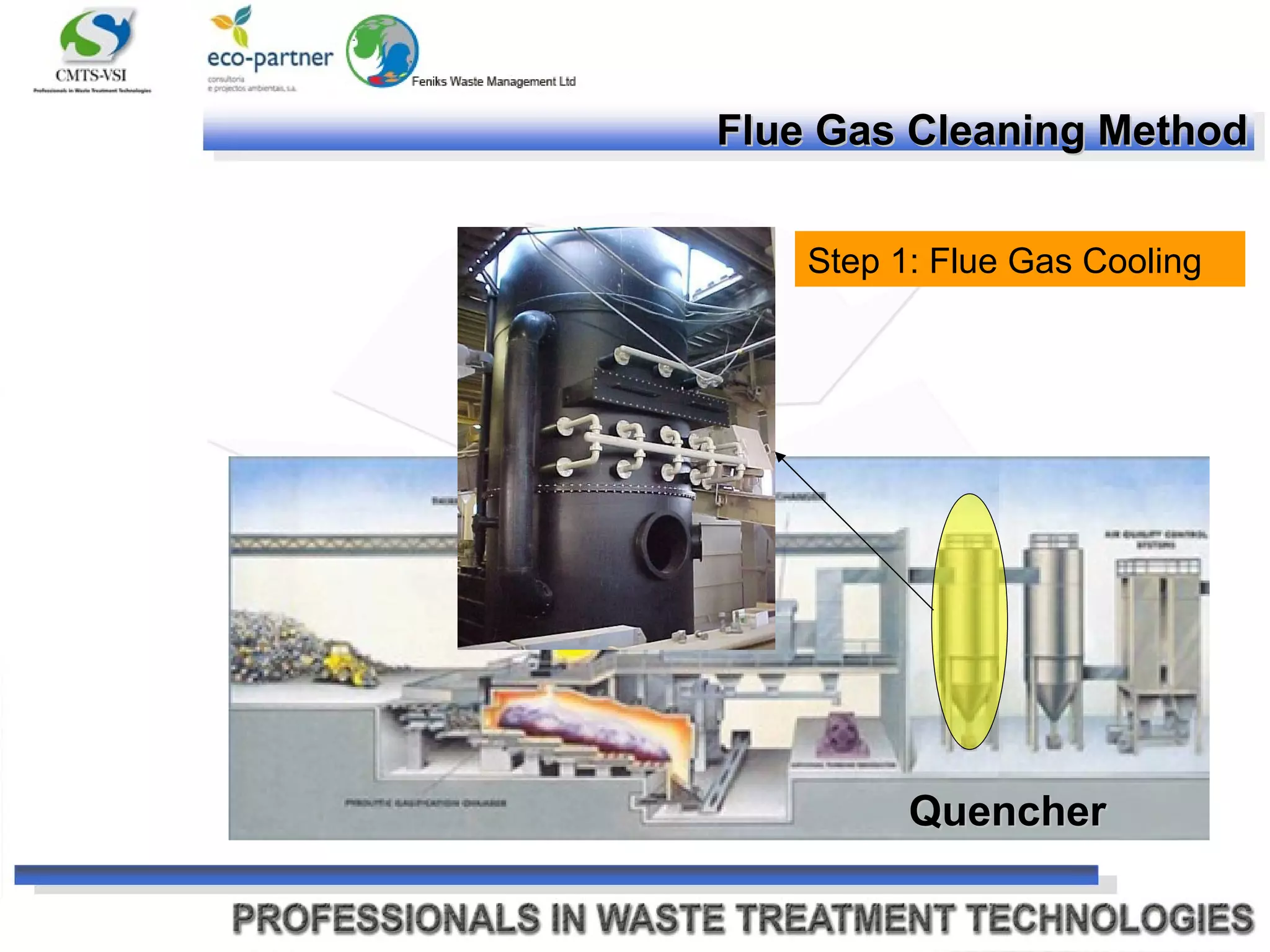

Feniks Waste Management LTD provides thermal waste treatment technologies and has experience designing waste-to-energy plants. Their mission is to contribute to a sustainable environment through advanced technology solutions for waste management. They offer integrated solutions for municipal solid waste treatment including sorting, composting, anaerobic digestion, gasification, and flue gas cleaning.