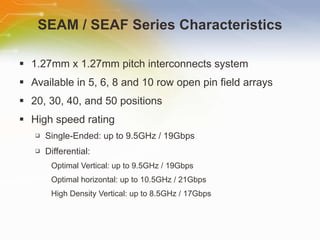

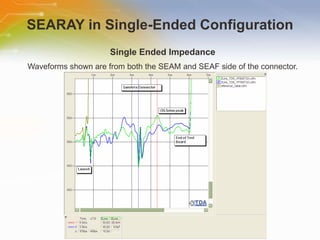

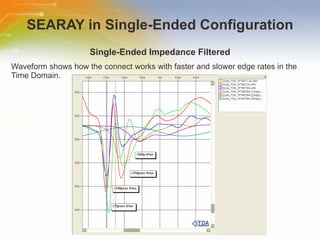

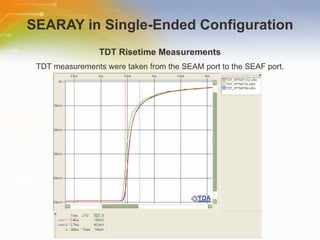

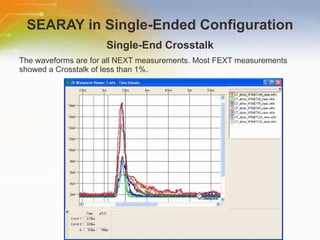

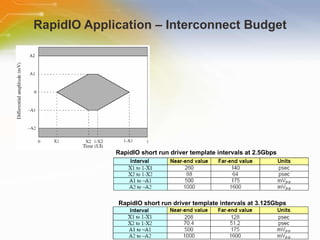

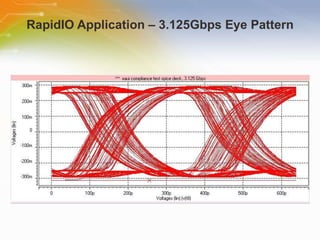

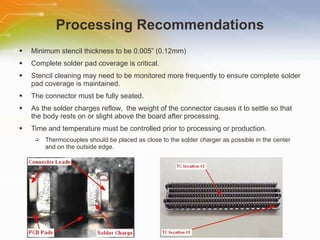

SEARAY is a high density, high speed board-to-board interconnect system from Samtec with up to 500 I/Os and 1.27mm pitch. It can be configured for single-ended or differential signaling with performance up to 10.5GHz. The document discusses SEARAY's applications in RapidIO and recommends a minimum stencil thickness of 0.005" for processing.