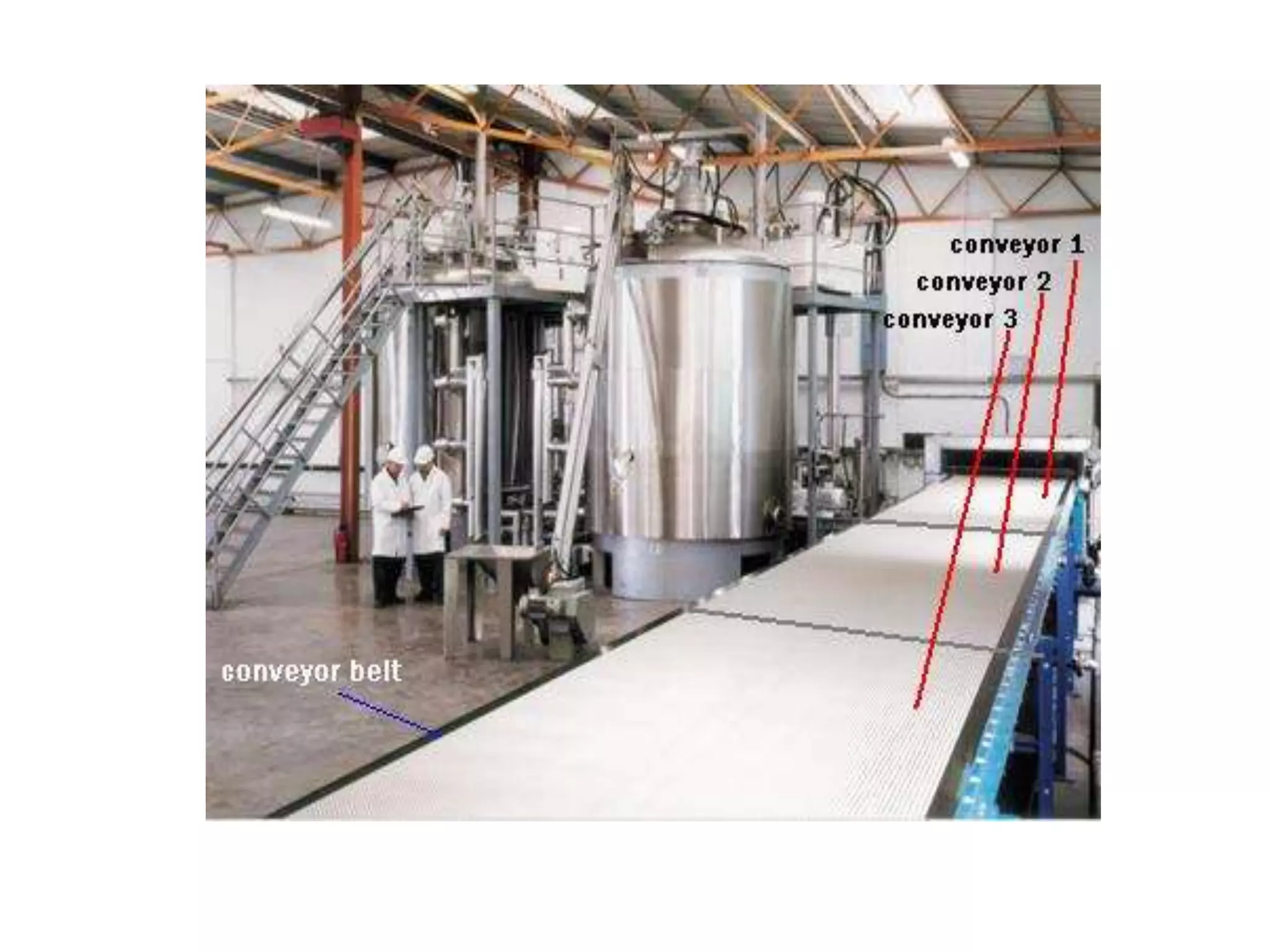

A PLC is used to control a conveyor system that transports copper plates. The system has three segmented conveyor belts, with each segment powered by a motor. A proximity switch at the end of each belt segment detects the position of the copper plate. The first belt segment is always on, and the second segment turns on when the proximity switch in the first detects the plate, allowing only the sections carrying a plate to move. The PLC provides automated control of the conveyor motors based on input from the proximity sensors to efficiently transport the plates along the production line.

![Gandhinagar Institute of Technology

Subject :- Control Engineering

MECHANICAL ENGINEERING

5th - B : 2

Presentation

on

Plc in conveyor system

– Mayank Bhatnagar [130120119100]

Pavan Narkhede [130120119111]](https://image.slidesharecdn.com/plc-151231104055/75/PLC-1-2048.jpg)