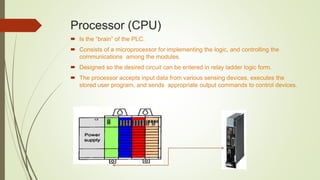

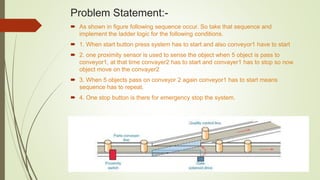

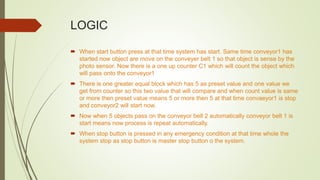

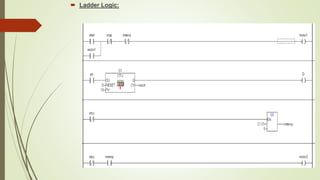

This document presents a programmable logic controller (PLC) system for controlling two conveyor belts. It includes an overview of PLCs and their components like the processor. It then provides a problem statement to design ladder logic to control two conveyor belts based on conditions like starting on a start button press and proximity sensors detecting objects. The solution section shows the ladder logic diagram and variables used, like inputs for start/stop buttons and sensors, and outputs to control the conveyor belts. It describes the logic flow of starting the first belt when started, counting objects with a counter, and starting the second belt when the count reaches 5 while stopping the first belt, then repeating by restarting the first belt once 5 objects pass the