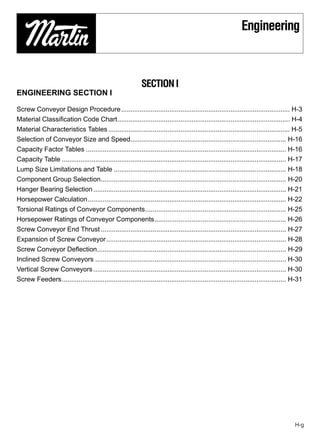

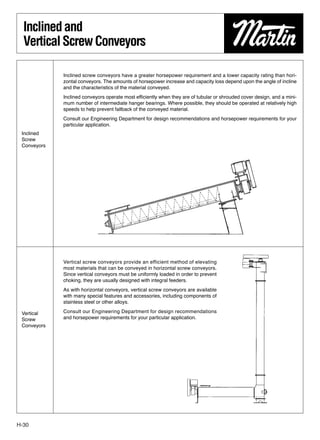

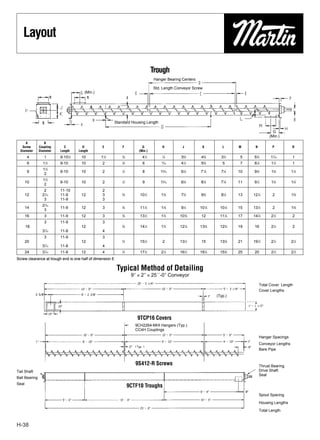

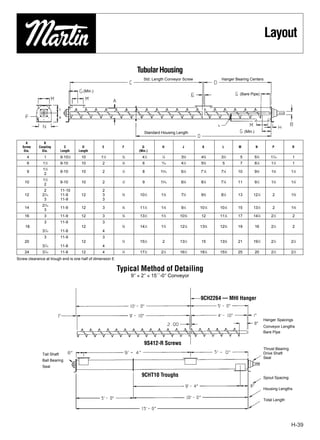

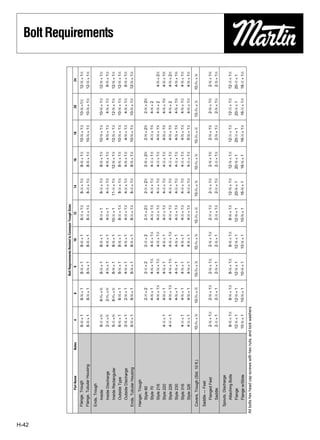

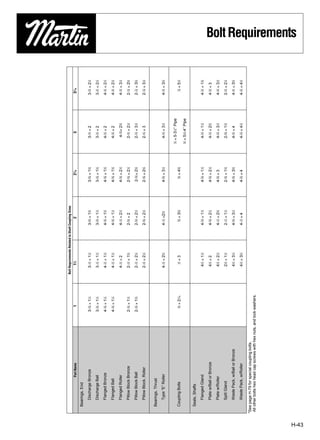

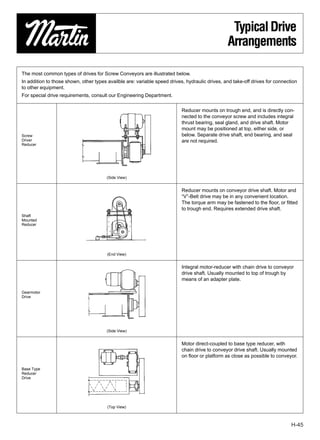

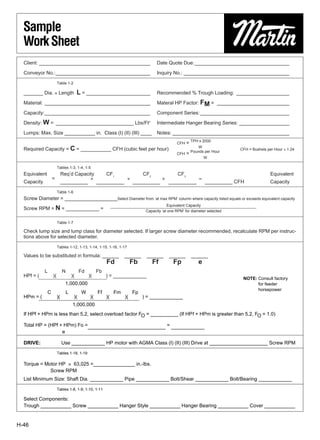

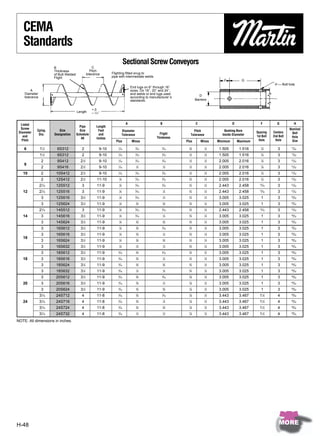

The document provides an overview of stock components for screw conveyors manufactured by Martin, including troughs, housings, ends, seals, flights, screws, hangers, bearings, reducers, and custom conveyors. It also includes engineering guidelines, charts, tables, and procedures for designing screw conveyors, selecting components, calculating capacity and horsepower, and addressing factors like material characteristics, lump size, thrust, expansion, deflection, and various conveyor types.