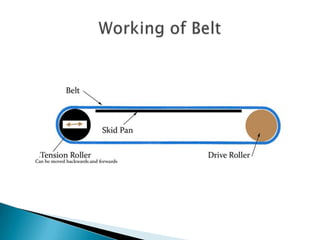

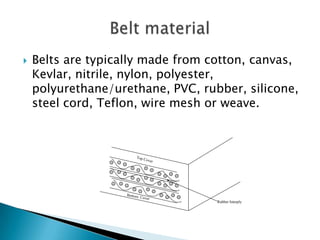

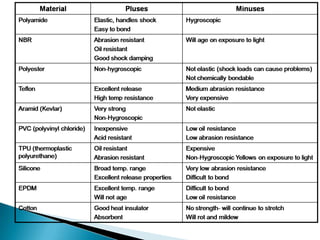

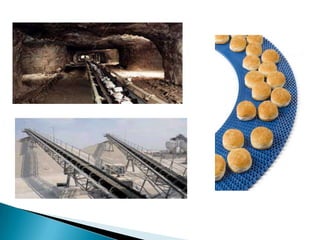

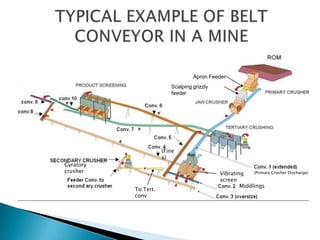

Conveyor belts are used widely in industry to transport materials. They consist of an under layer called the carcass for strength and an over layer called the cover. Belts are made of materials like rubber, plastic, or cotton. The type of belt used depends on the size, weight, and shape of items being moved. Benefits of belt conveyors include their ability to handle high capacities over long distances economically. They are suitable for abrasive, wet, dry, or dirty materials. However, belts may require higher tension and are susceptible to issues with sticky materials.