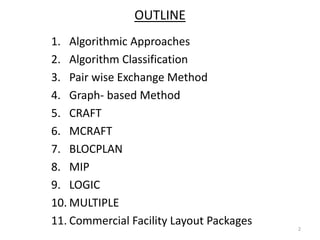

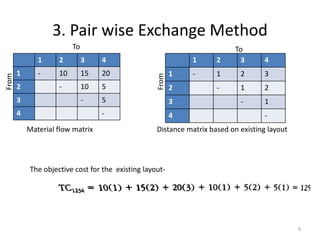

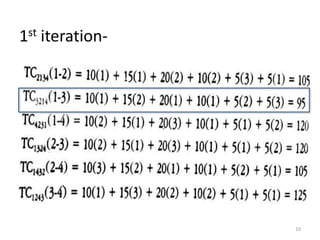

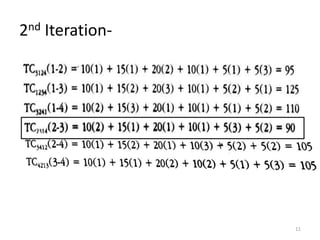

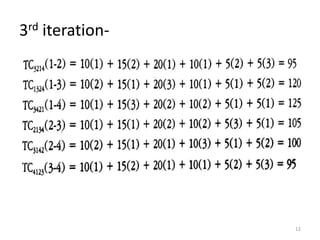

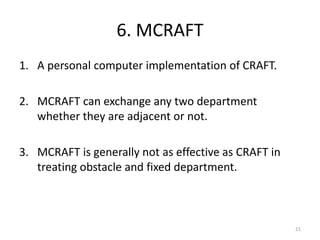

1) The document outlines various algorithms and software for solving plant layout problems, including pairwise exchange, graph-based, CRAFT, MCRAFT, BLOCPLAN, MIP, and LOGIC algorithms.

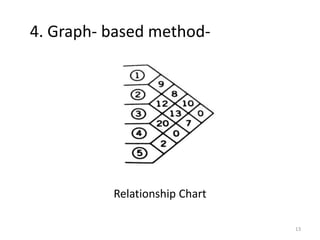

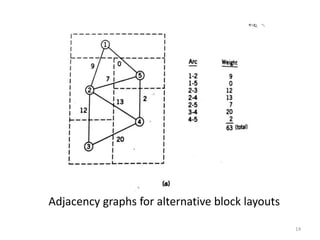

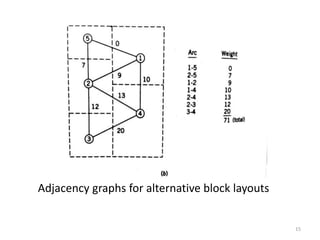

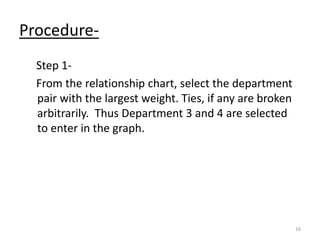

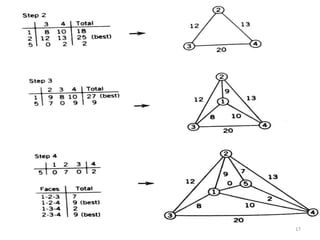

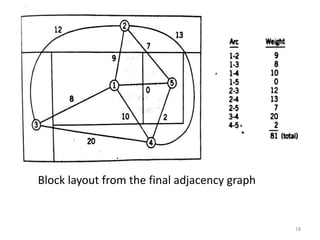

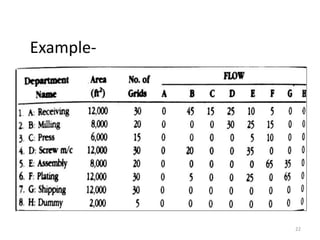

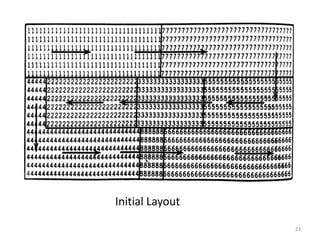

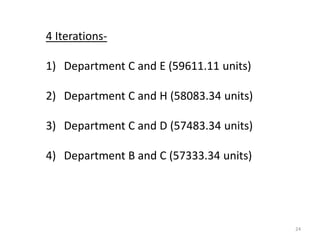

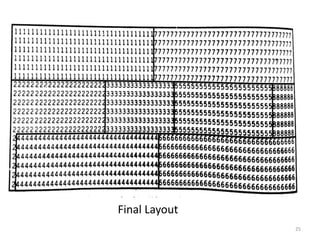

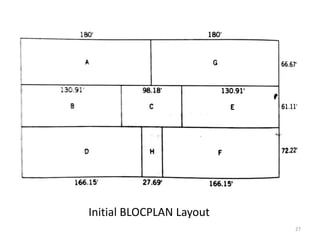

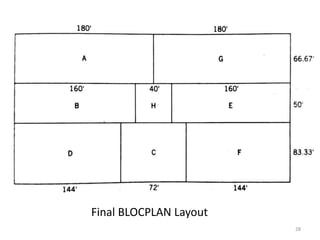

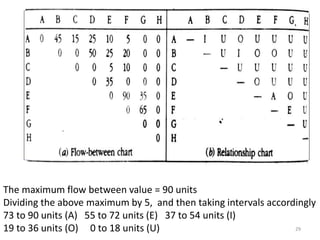

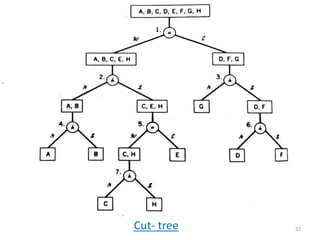

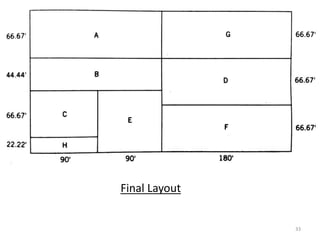

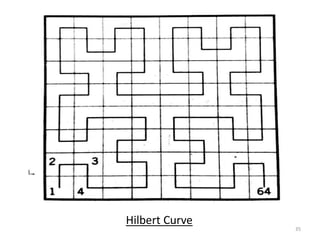

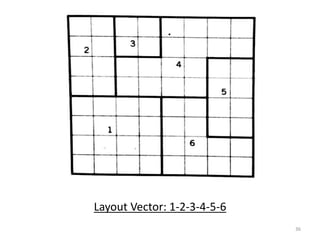

2) It provides details on each algorithm, including the objectives, inputs, procedures, and example outputs.

3) Finally, it lists several commercial facility layout software packages available from vendors such as Unigraphics Solutions, Production Modeling Corporation, Systemes Escape Temps, and Techomatrix Technologies.