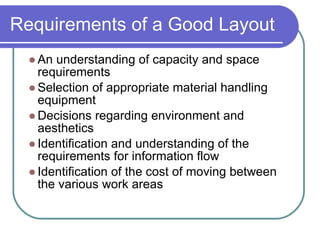

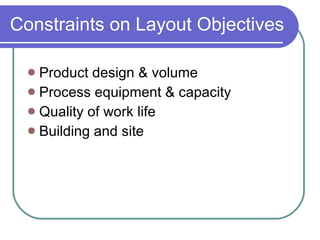

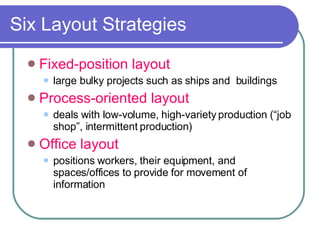

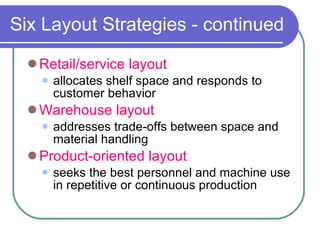

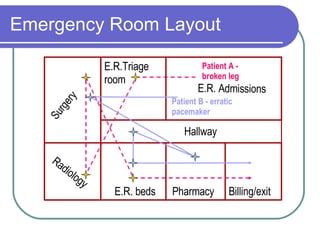

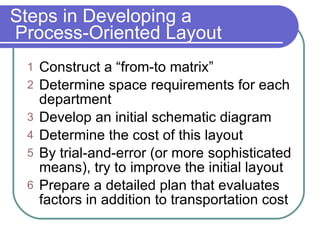

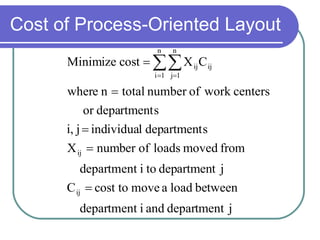

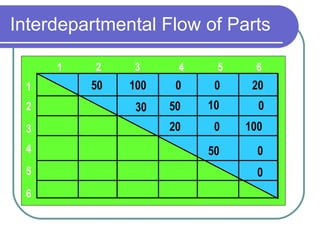

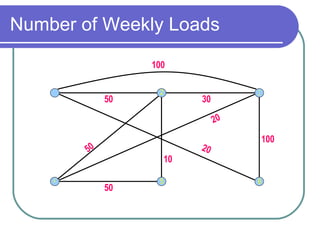

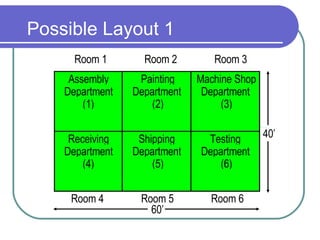

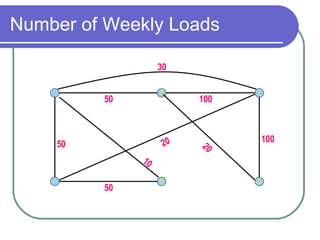

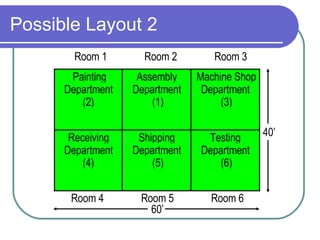

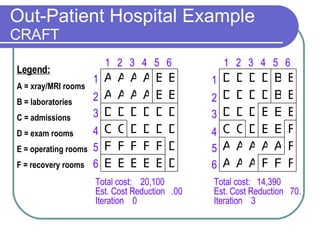

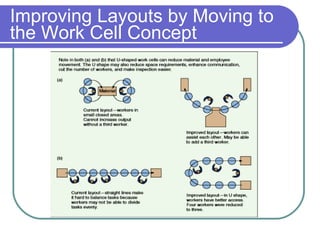

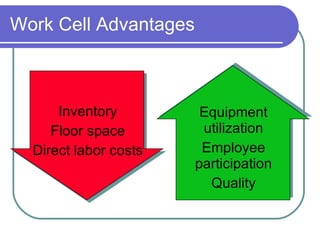

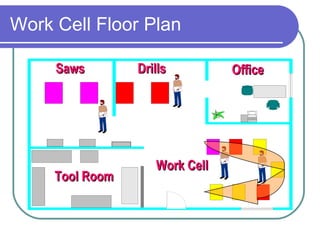

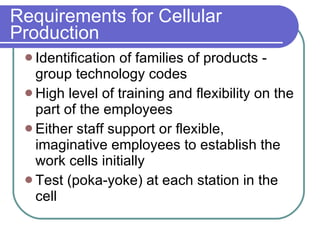

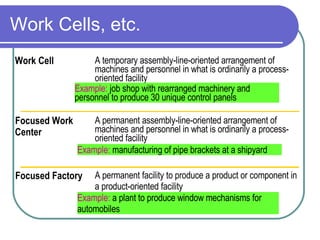

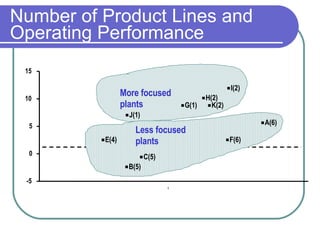

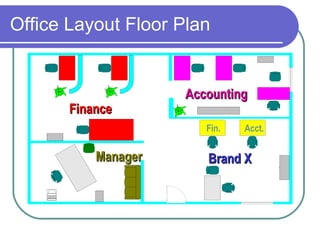

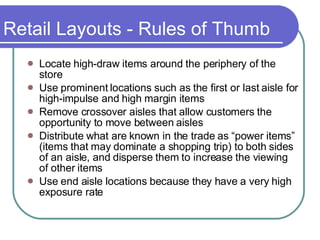

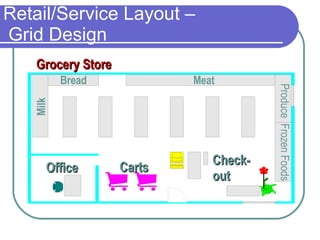

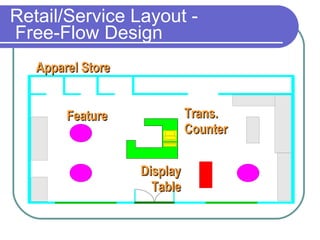

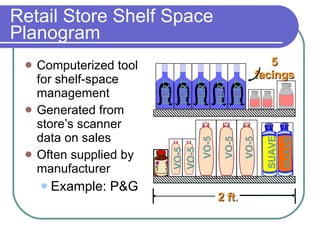

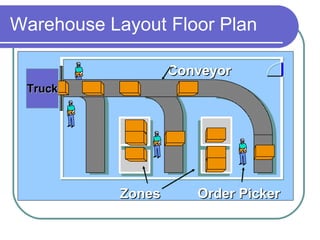

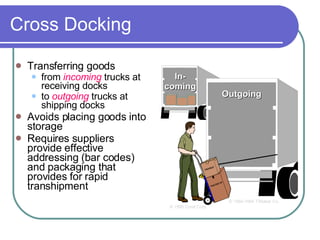

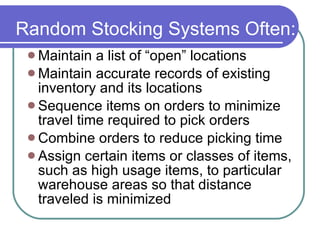

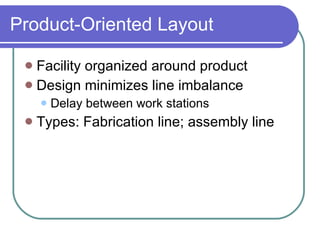

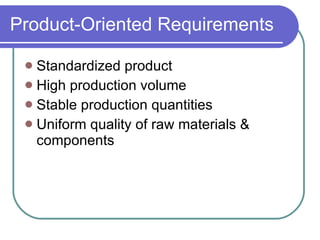

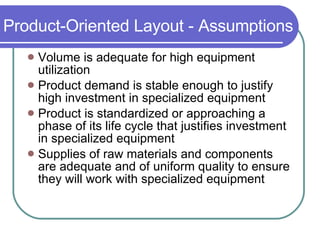

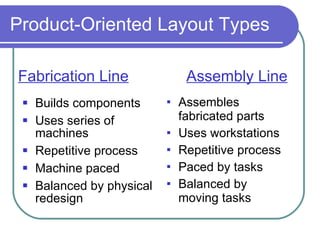

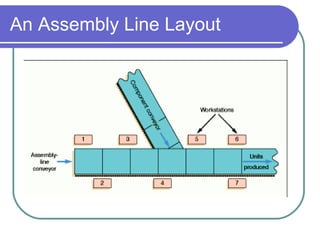

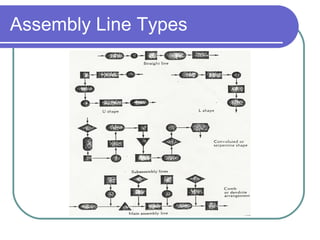

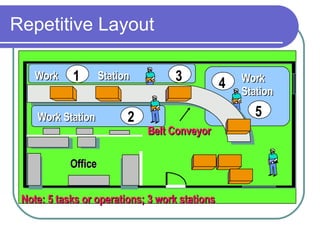

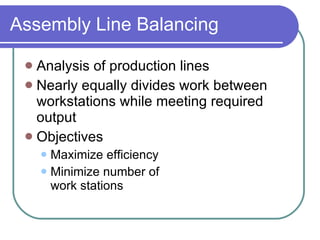

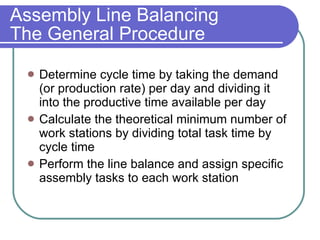

The document discusses various facility layout strategies, including their objectives, requirements, and types. It describes fixed-position, process-oriented, office, retail/service, warehouse, and product-oriented layout strategies. For each type, it provides examples and considerations for developing an optimal layout.