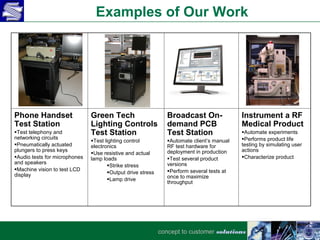

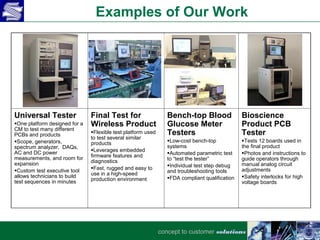

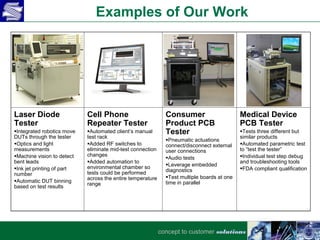

Solution Sources Programming is an engineering consulting firm that provides test engineering and functional test solutions. They have a staff of 11 test engineers and work with suppliers to design, build, and support test stations across various industries like electronics, medical devices, wireless products, and more. Their services include developing test strategies, building turnkey test stations, and providing ongoing support.