This document provides an overview of various tools and techniques used in electronics repair, including:

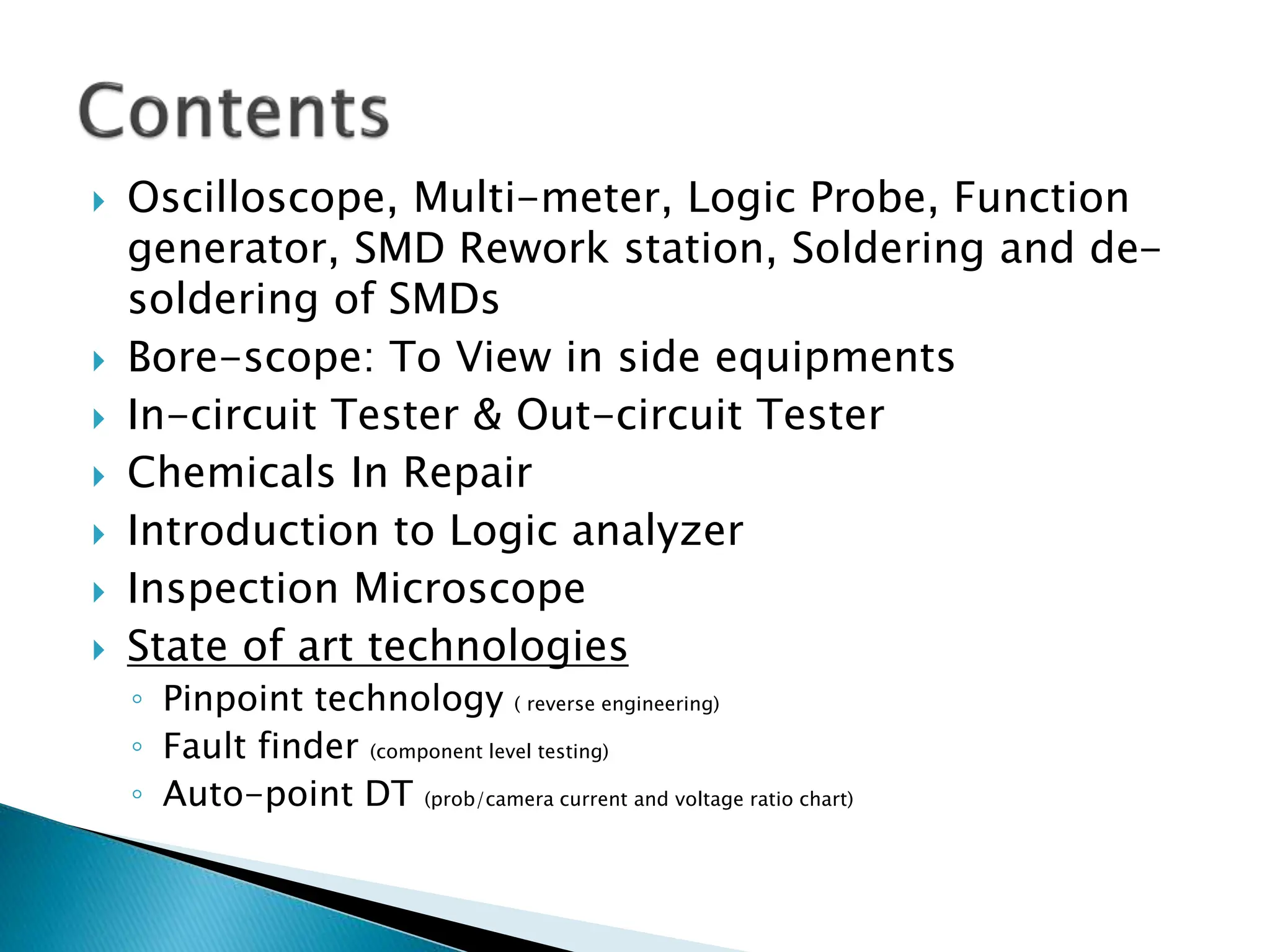

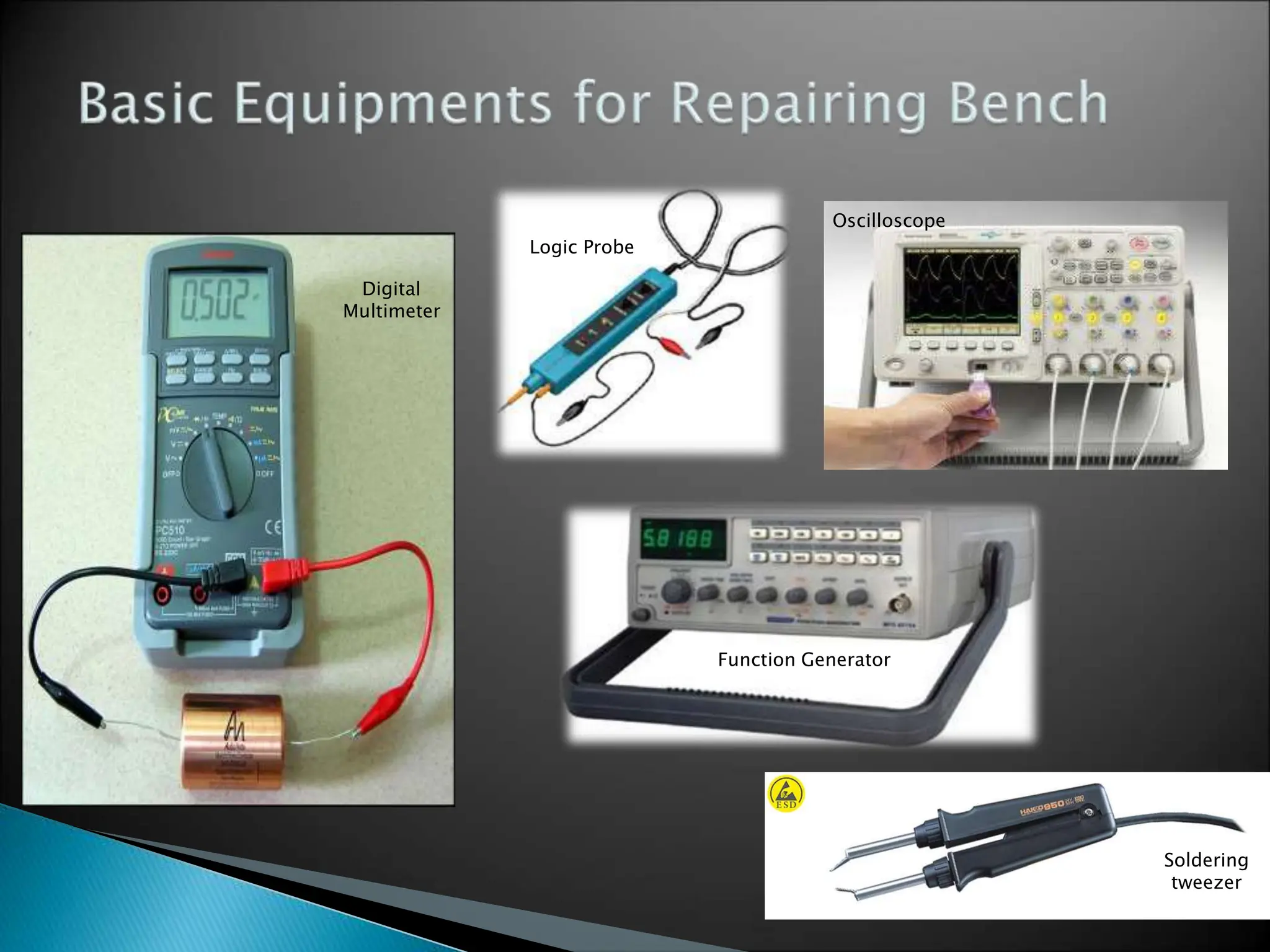

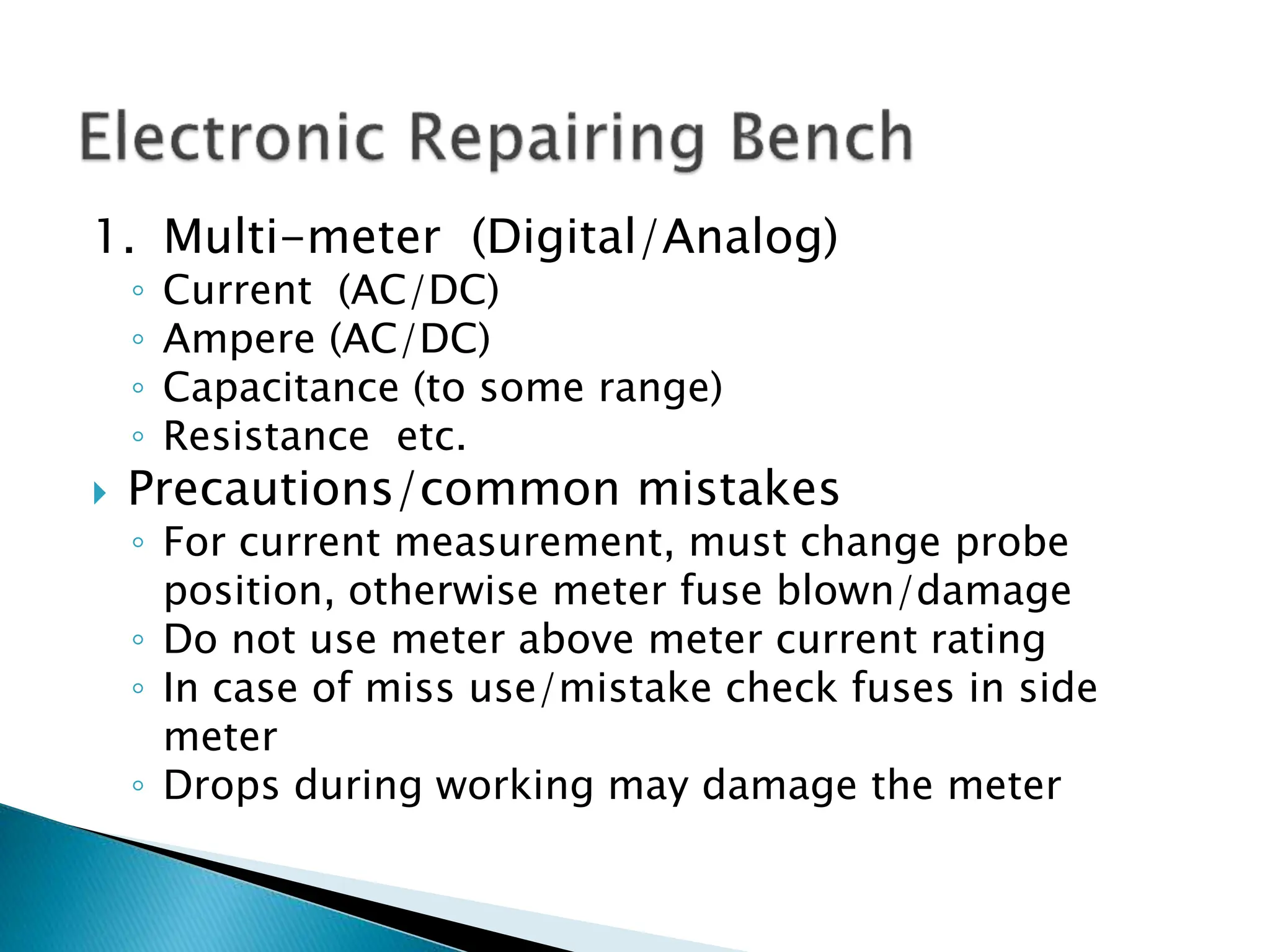

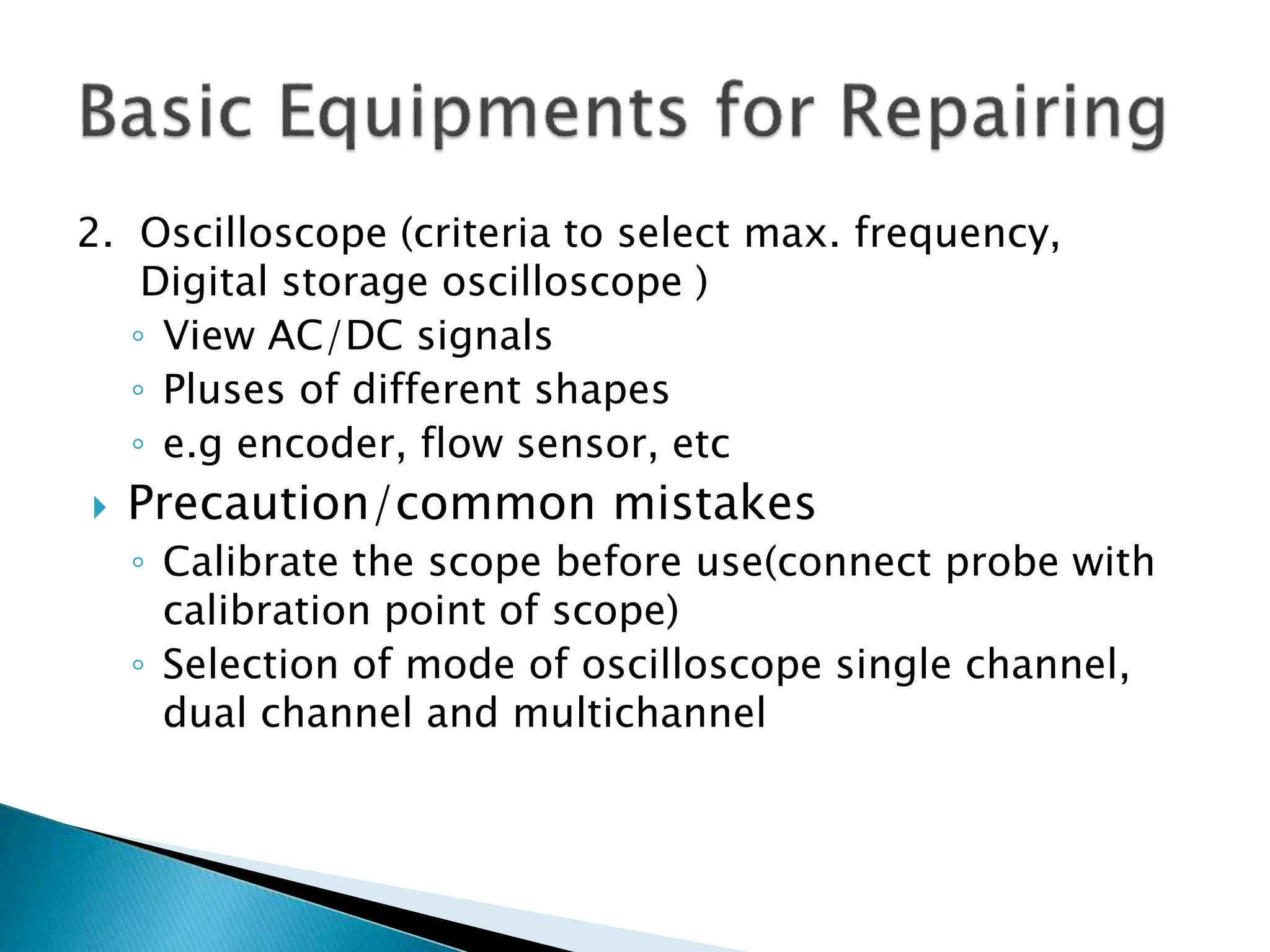

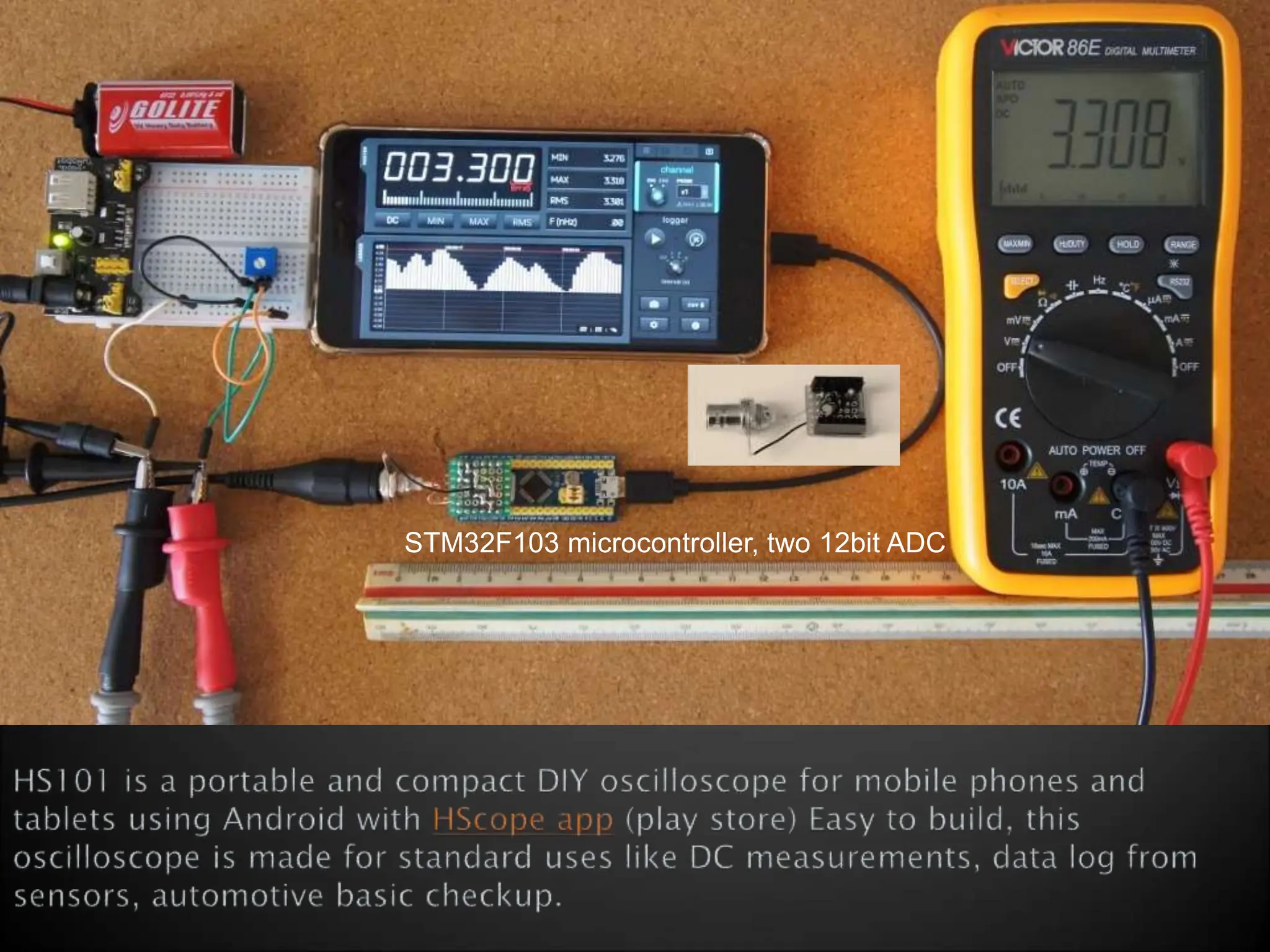

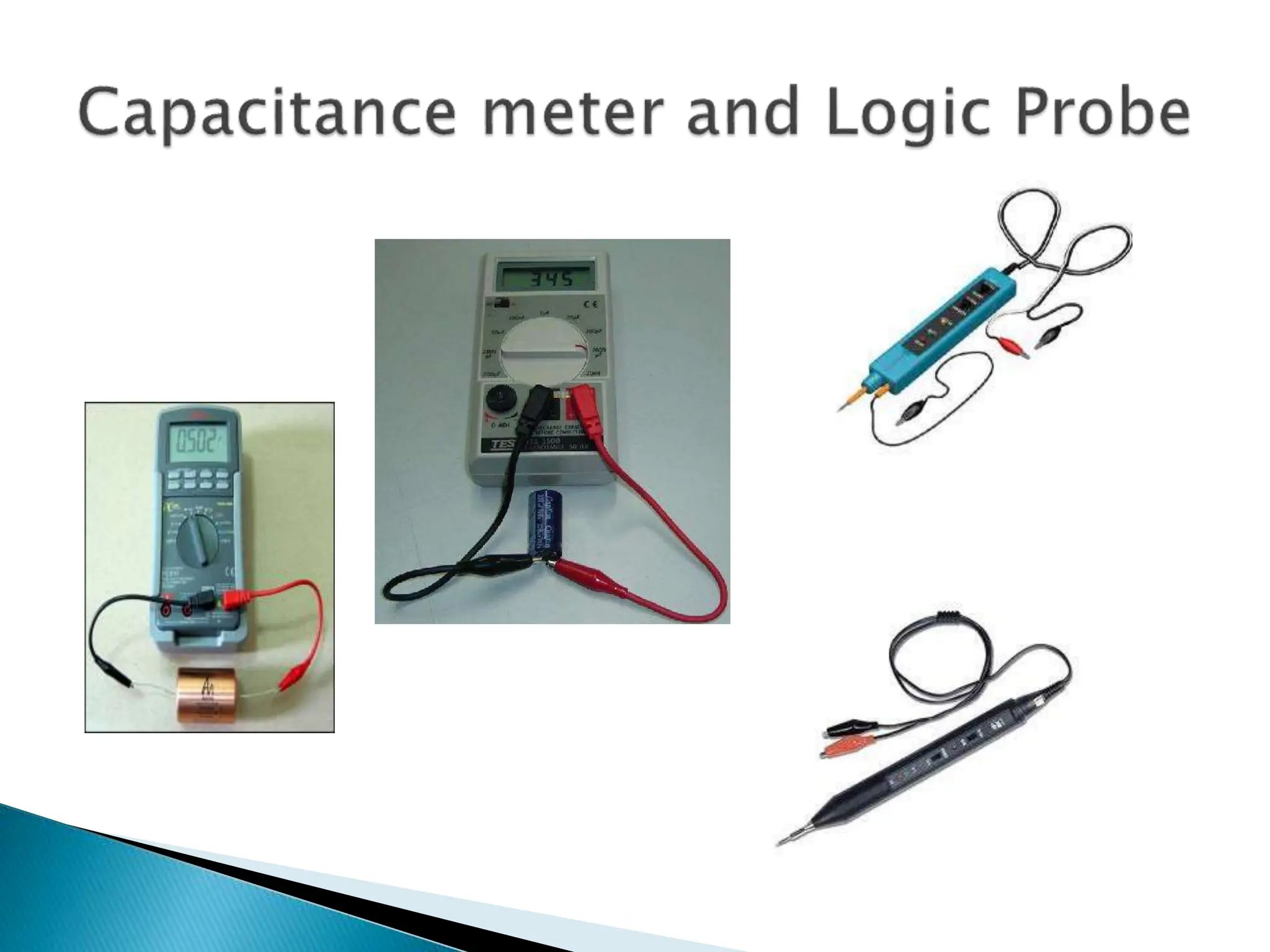

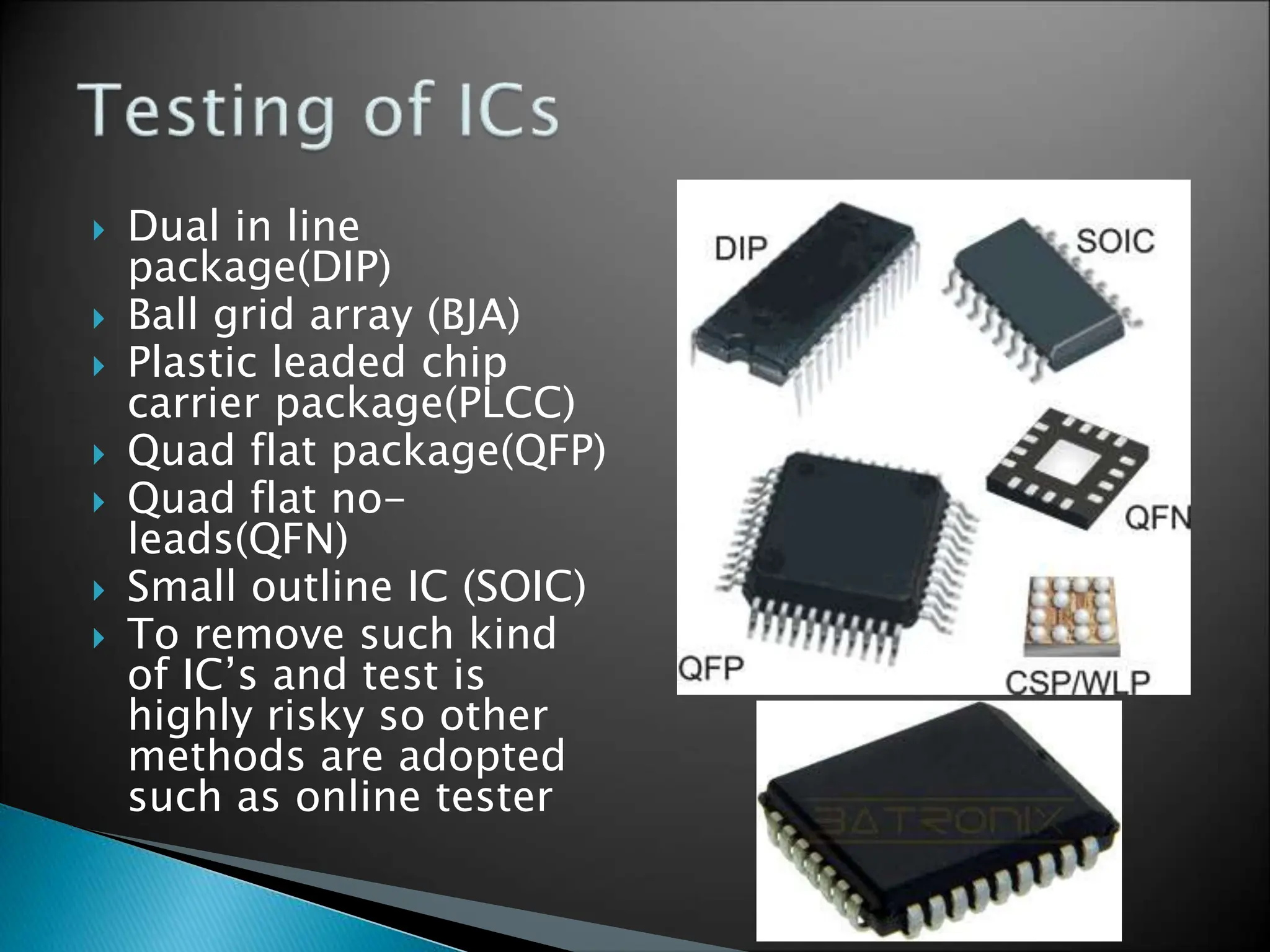

- Multi-meters, oscilloscopes, logic probes, and function generators for testing circuits.

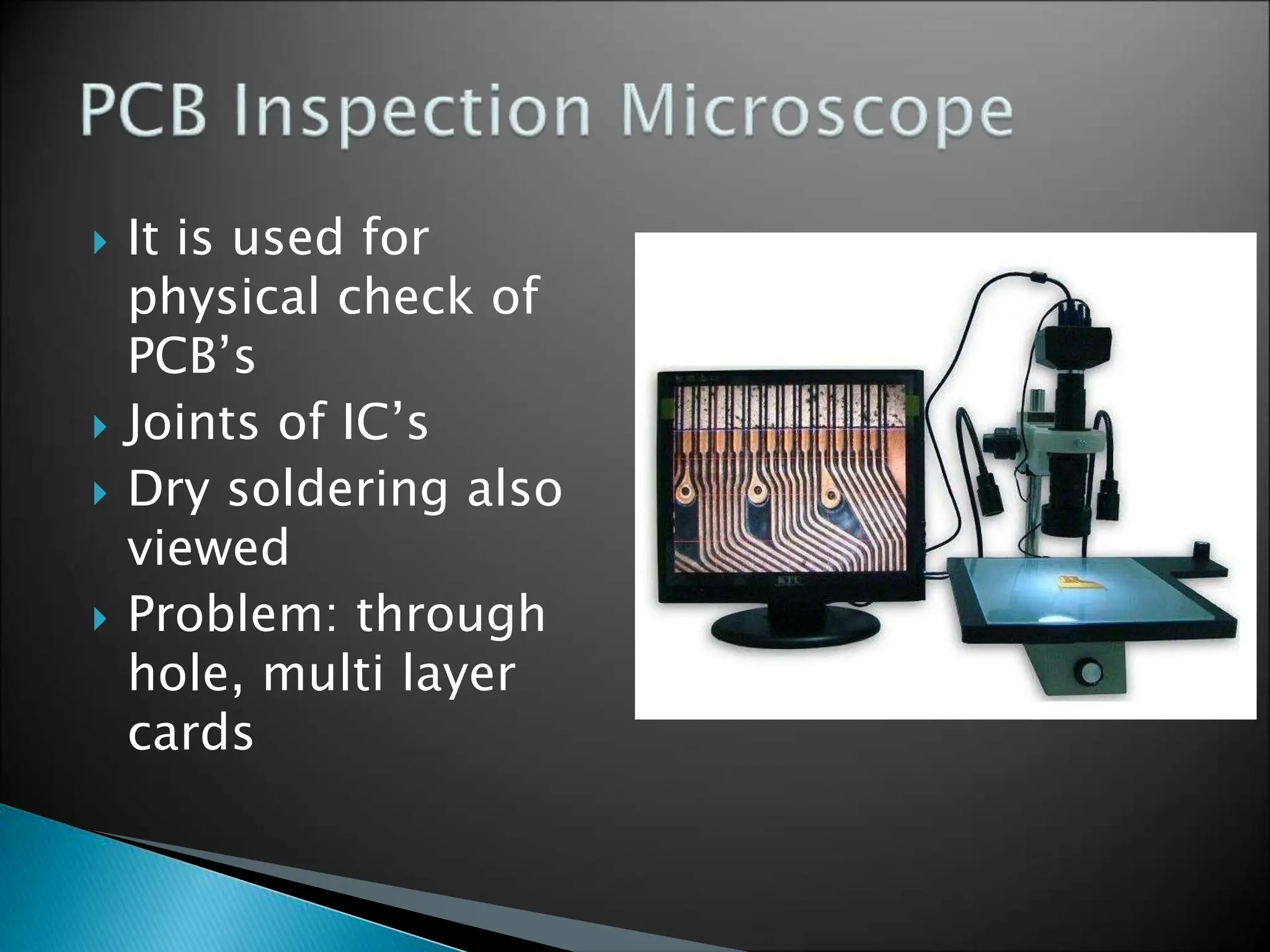

- Microscopes and borescopes for inspection.

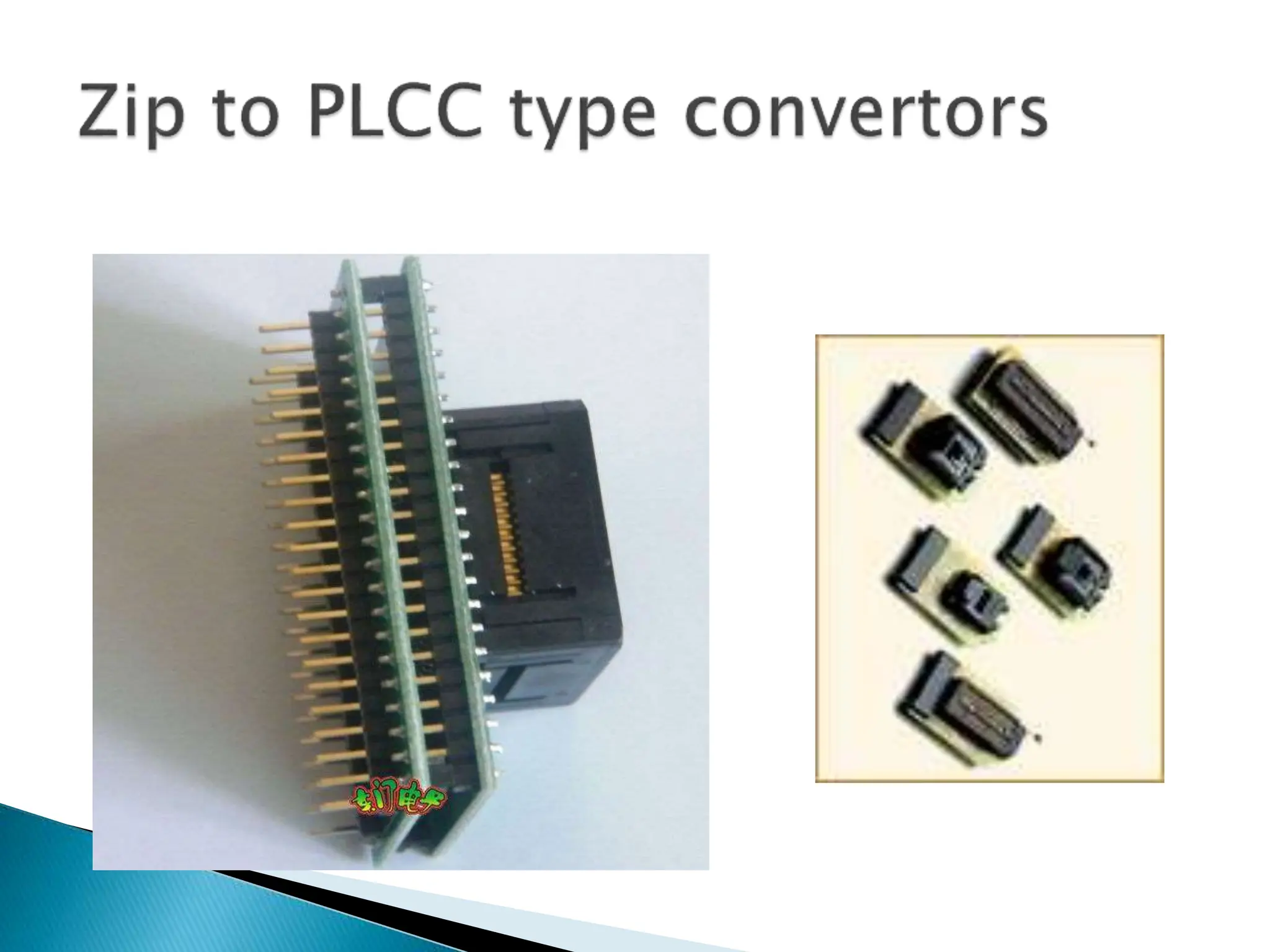

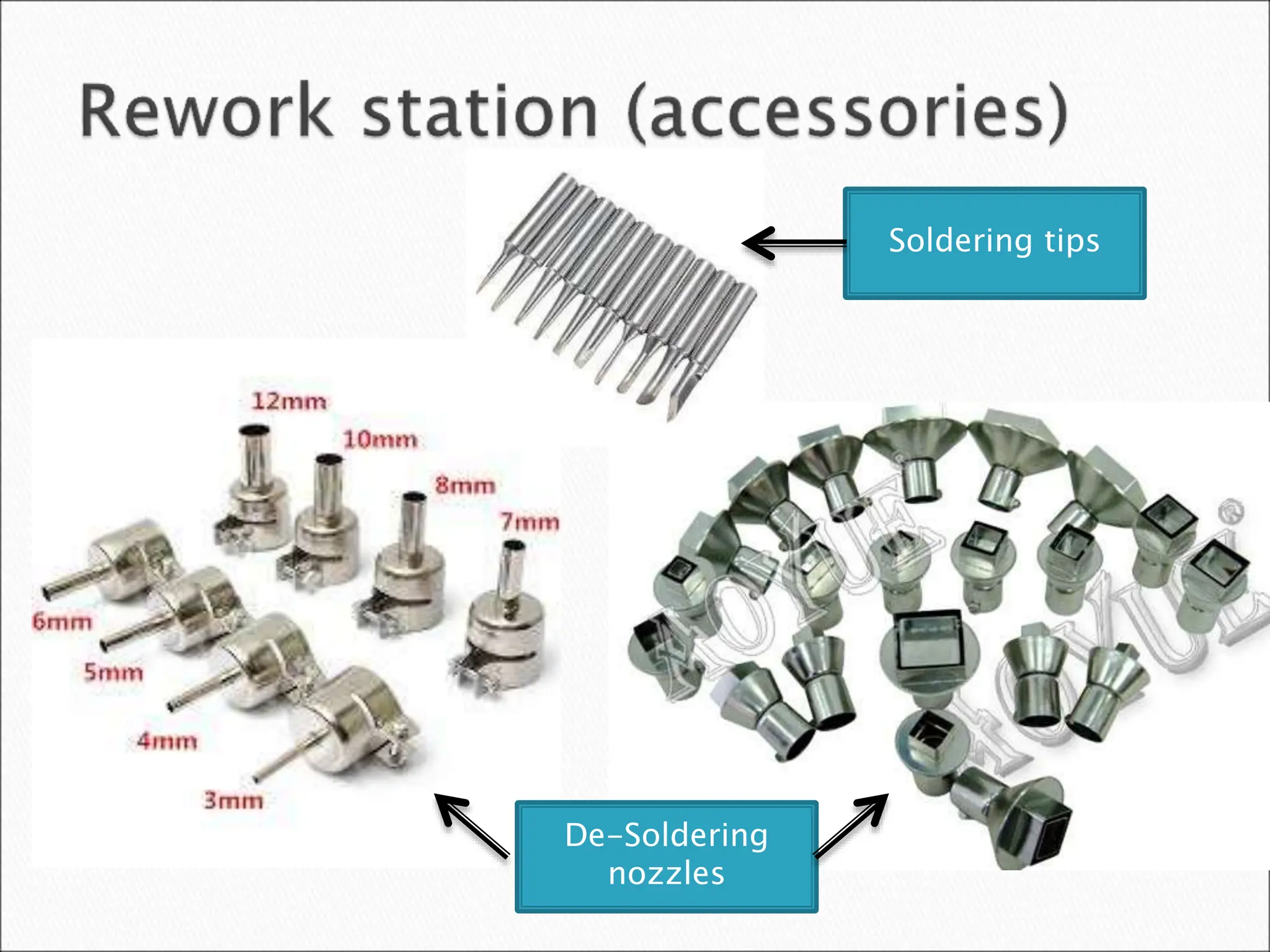

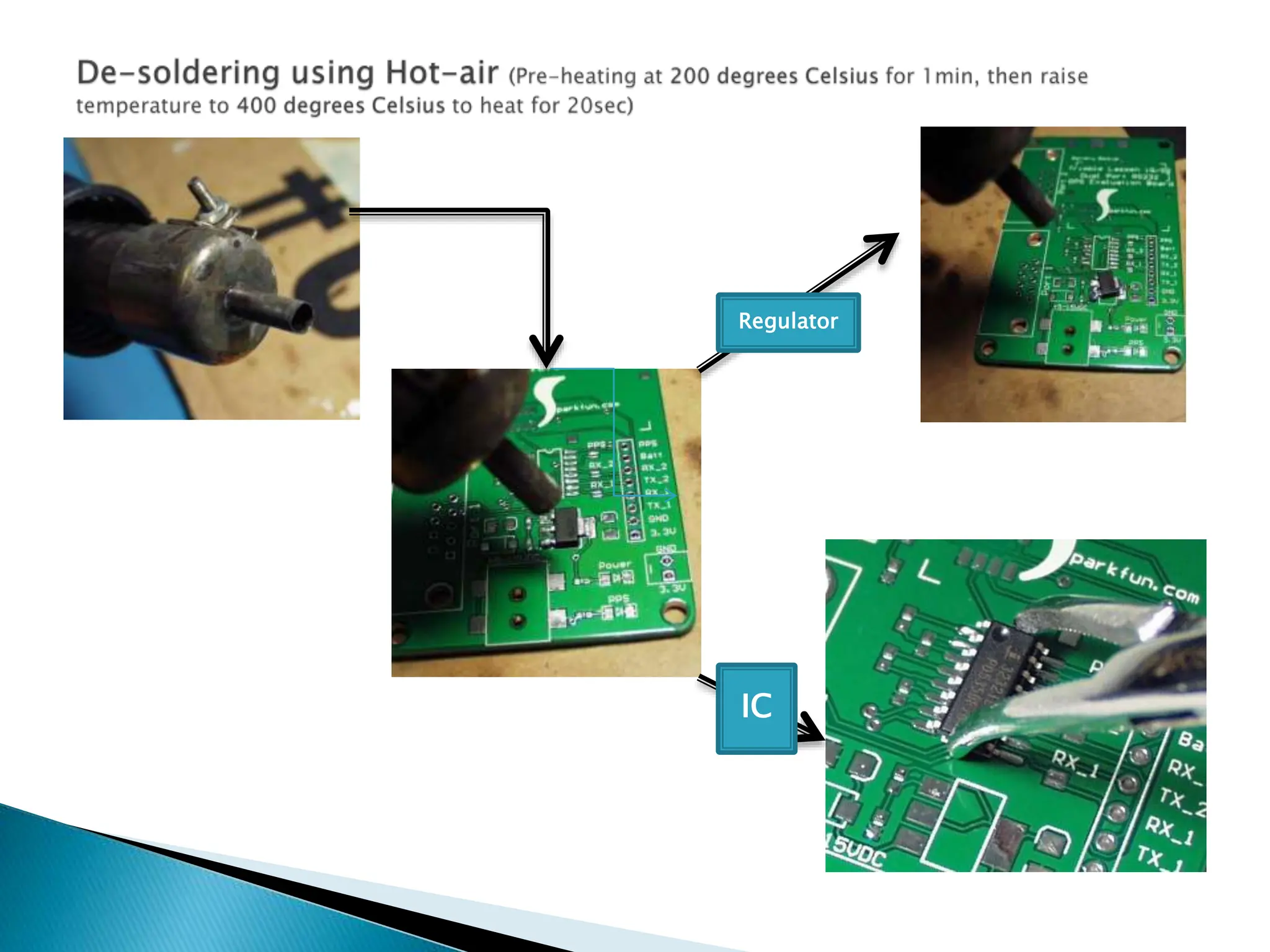

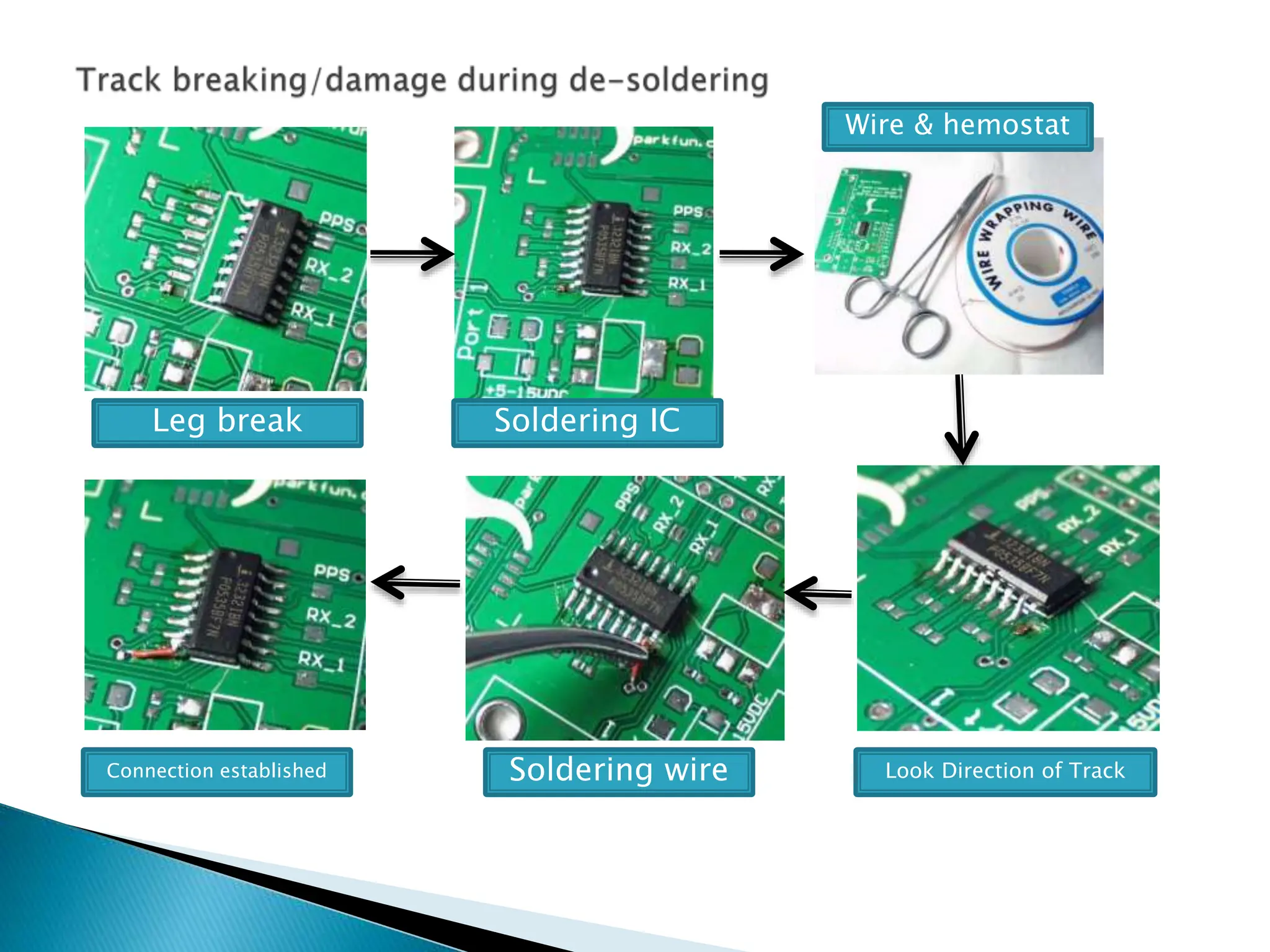

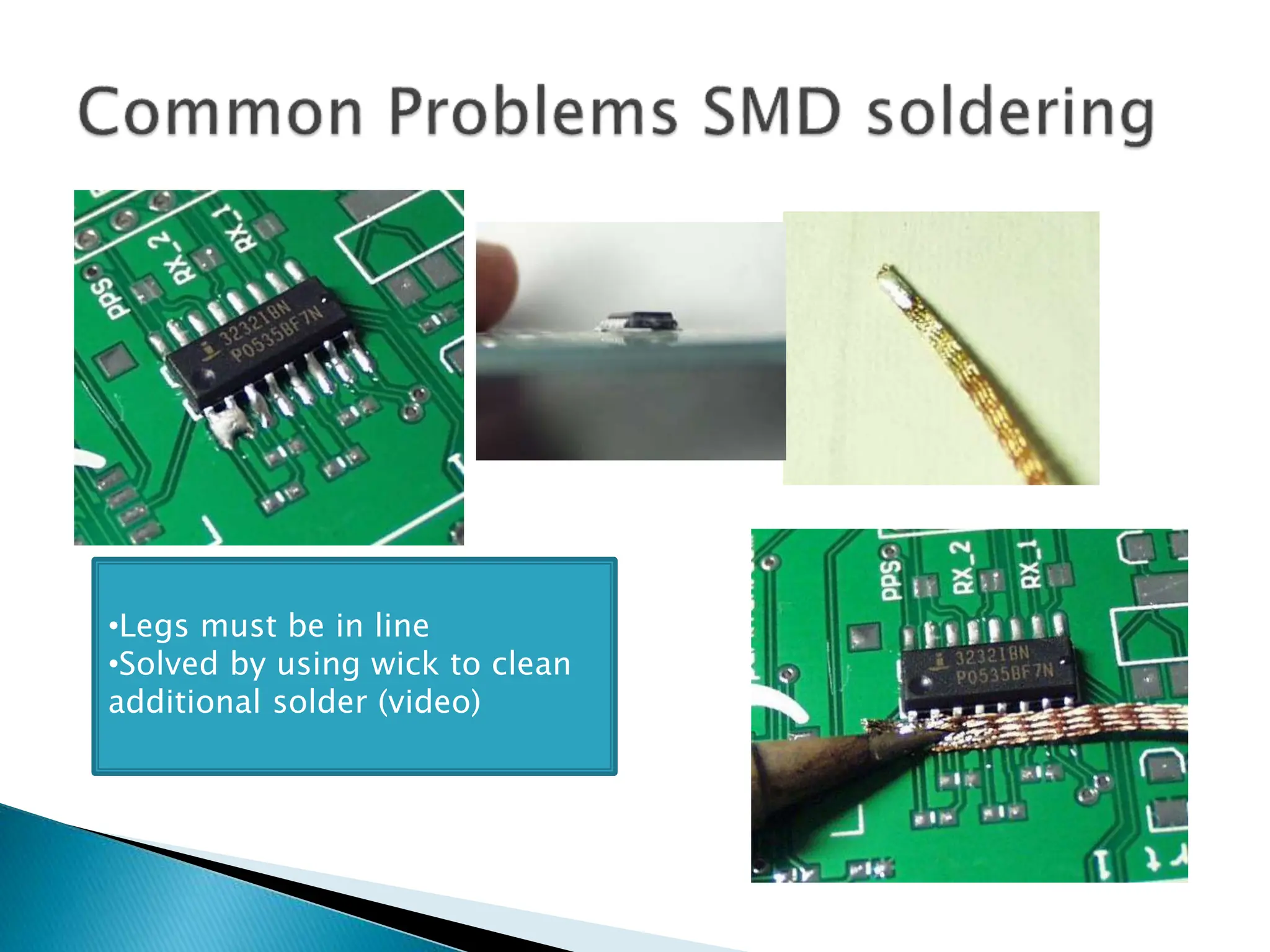

- Desoldering and soldering equipment for component-level repairs.

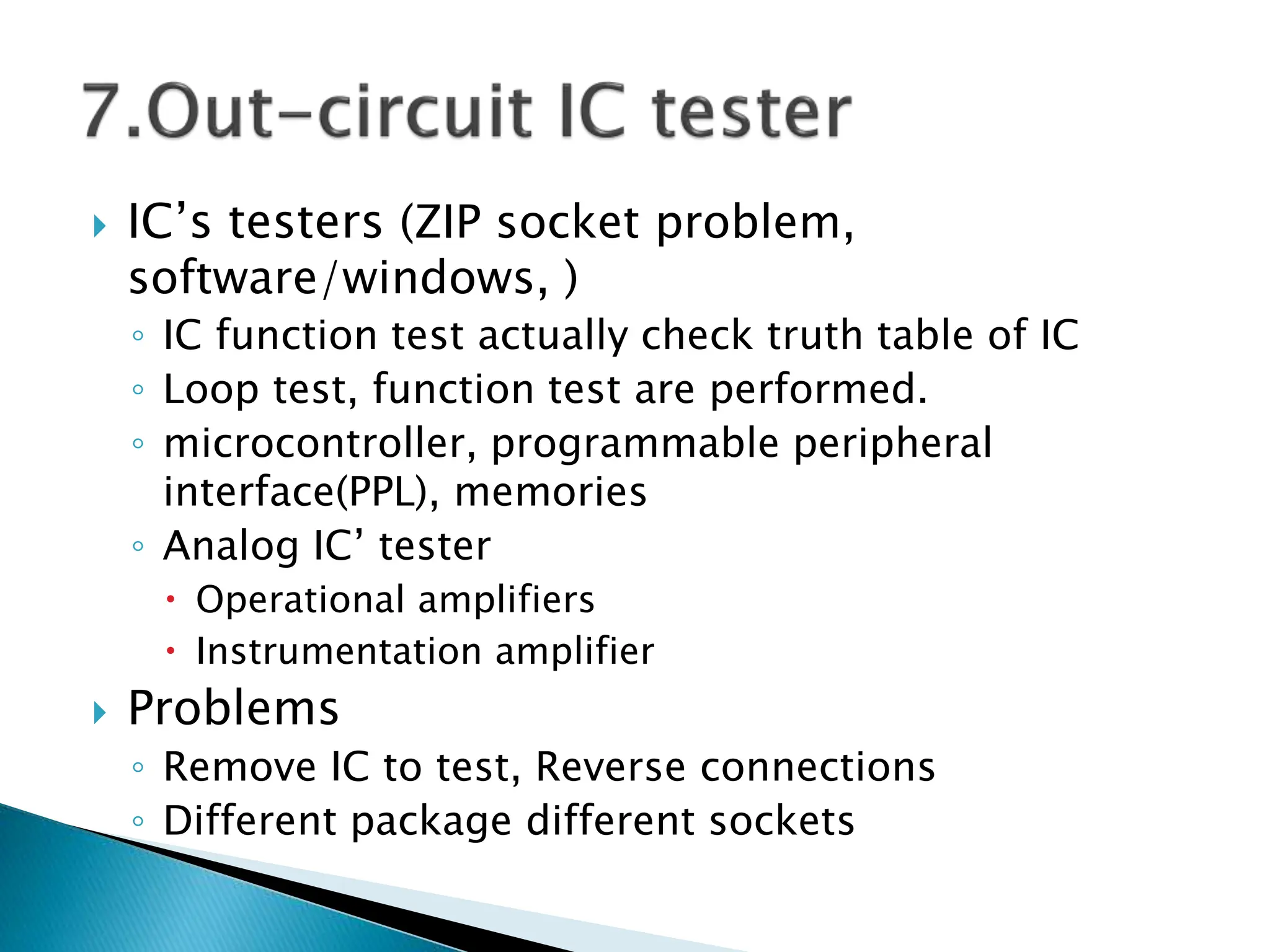

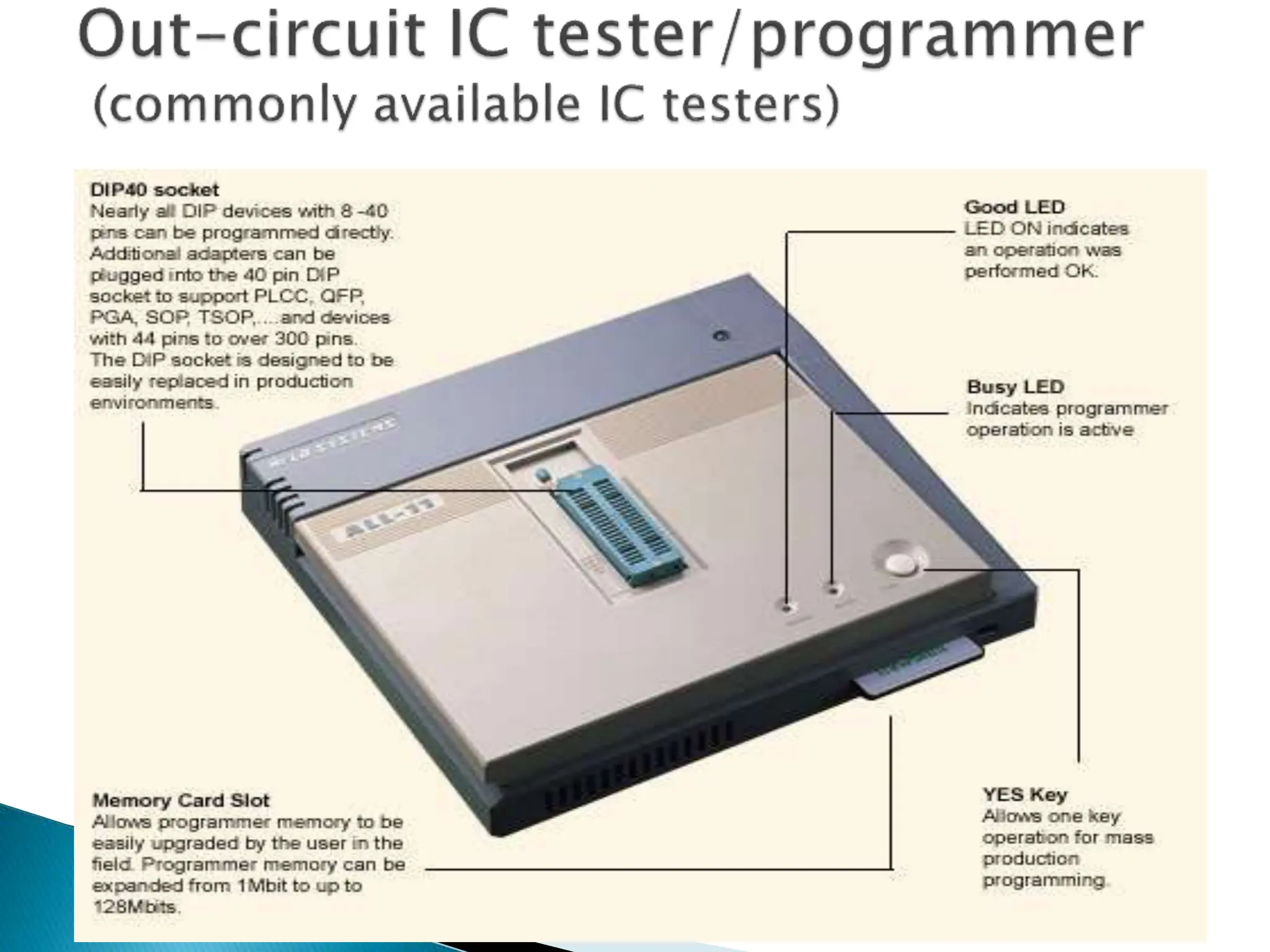

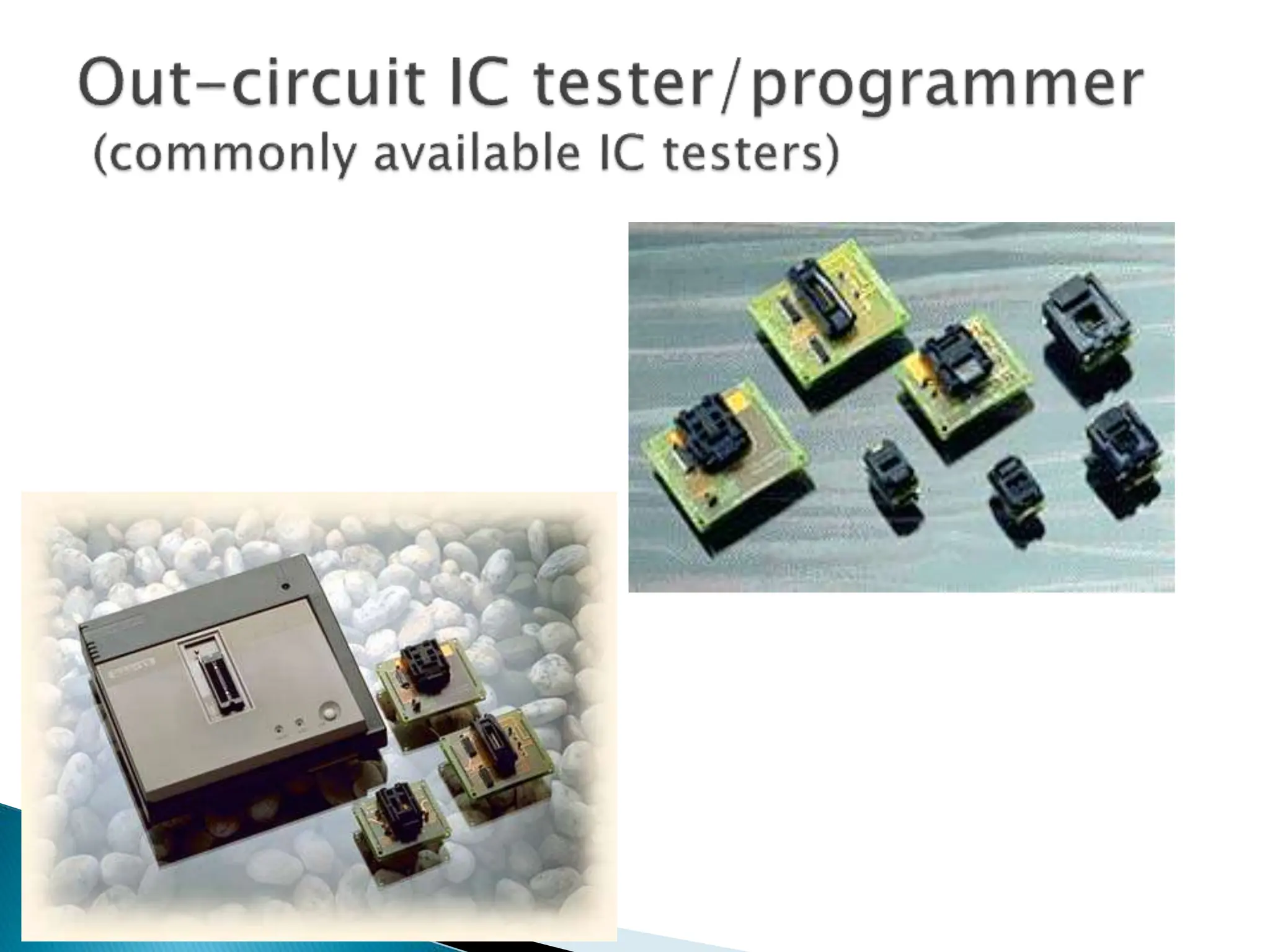

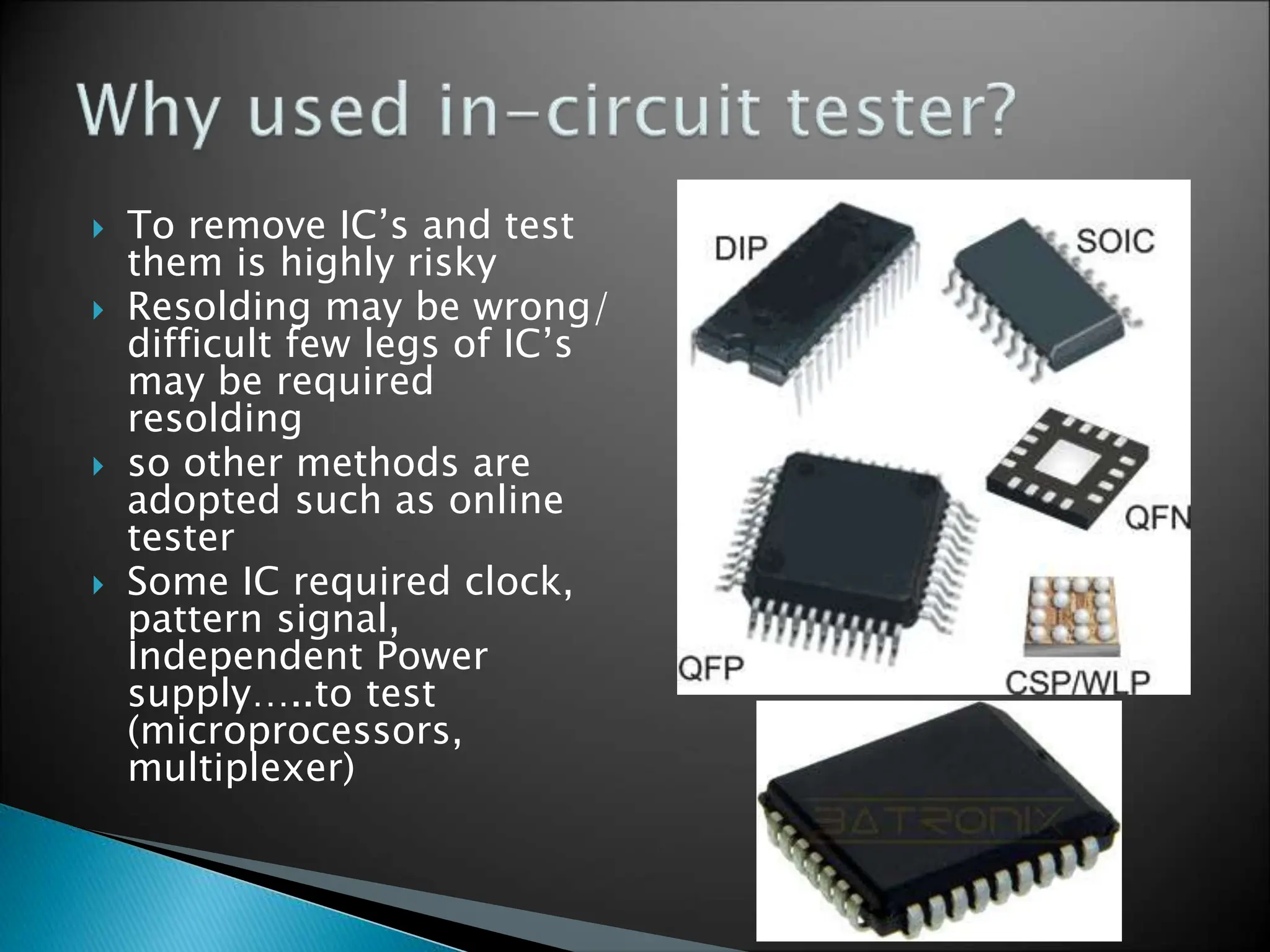

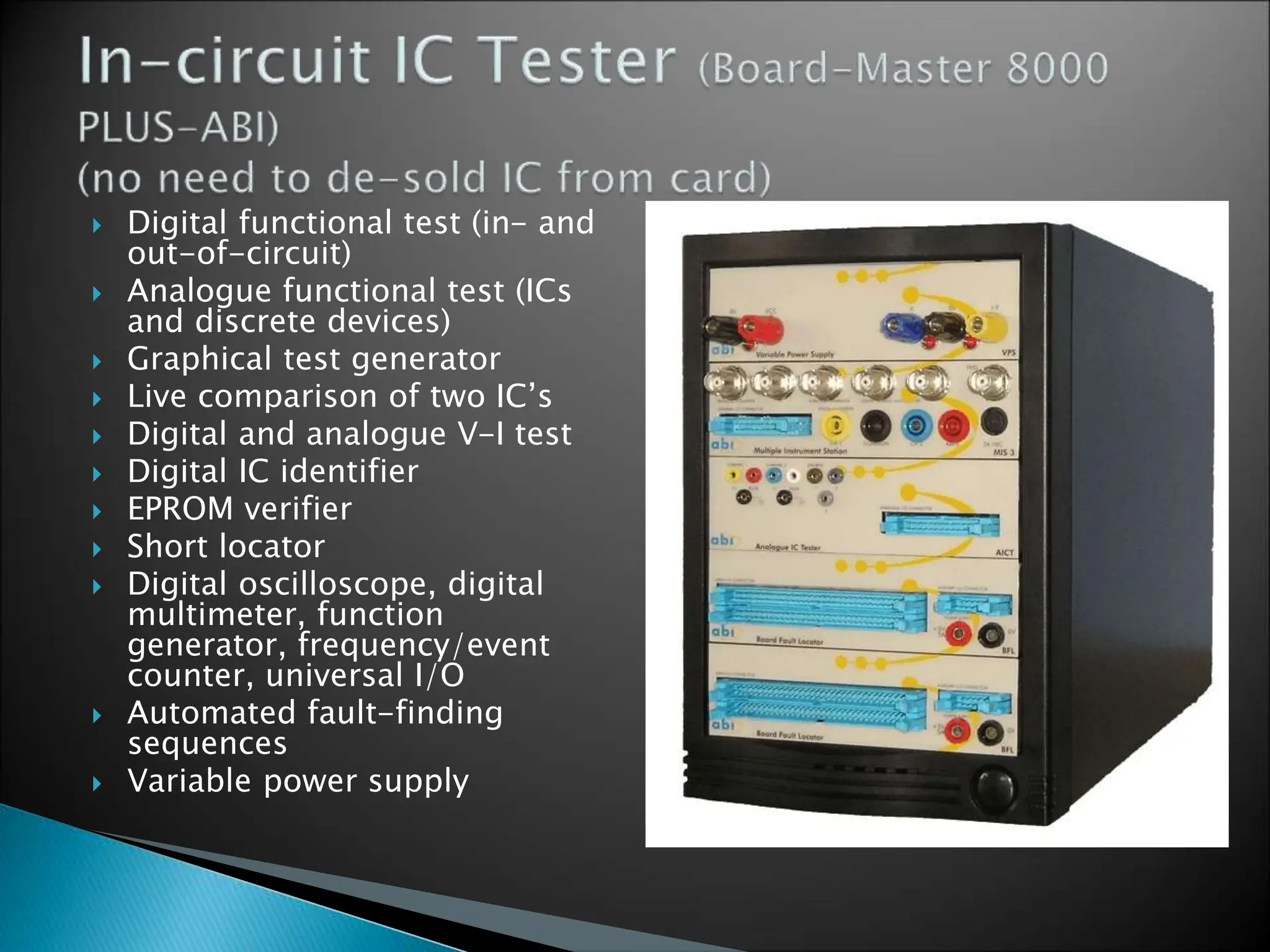

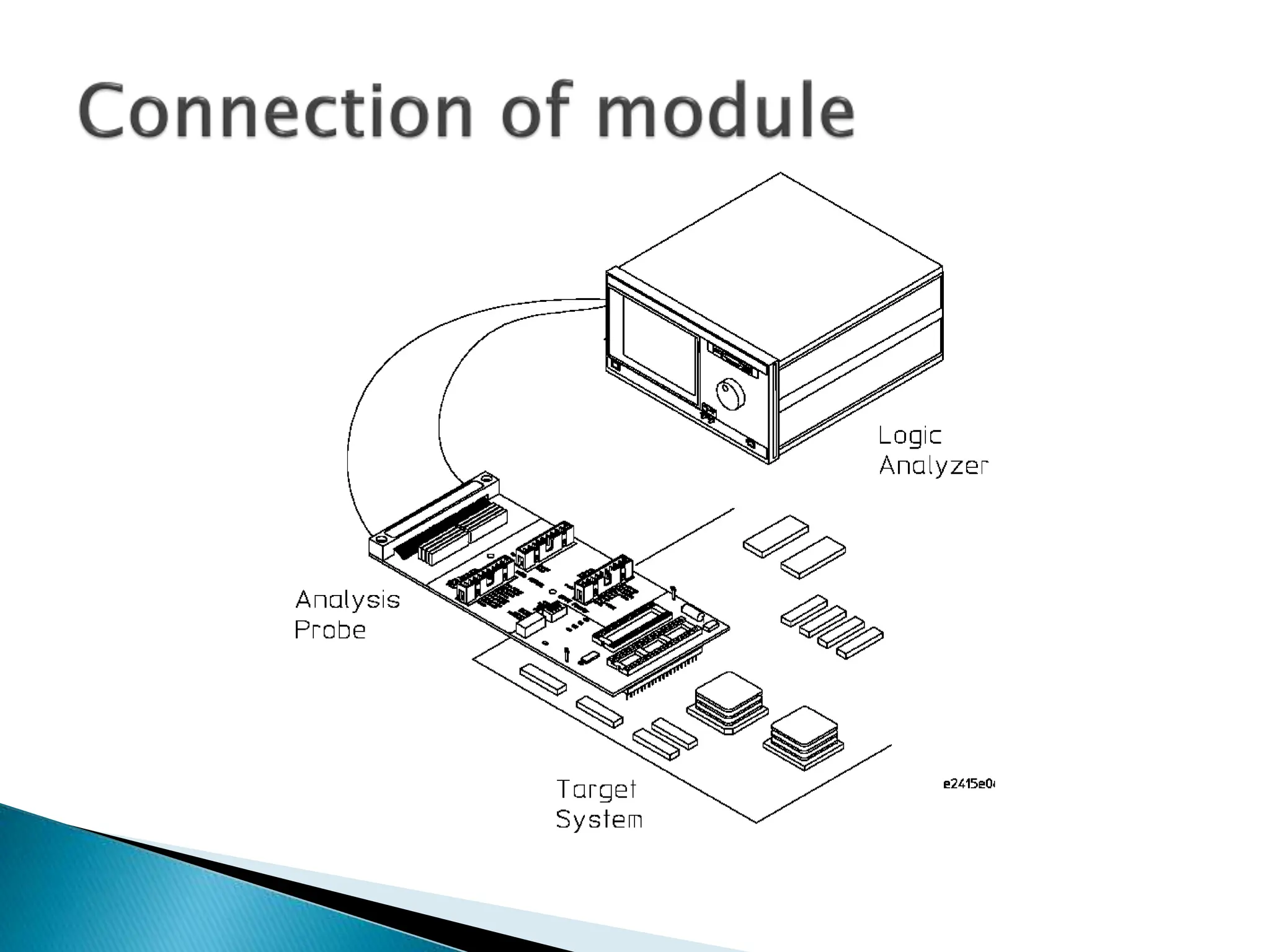

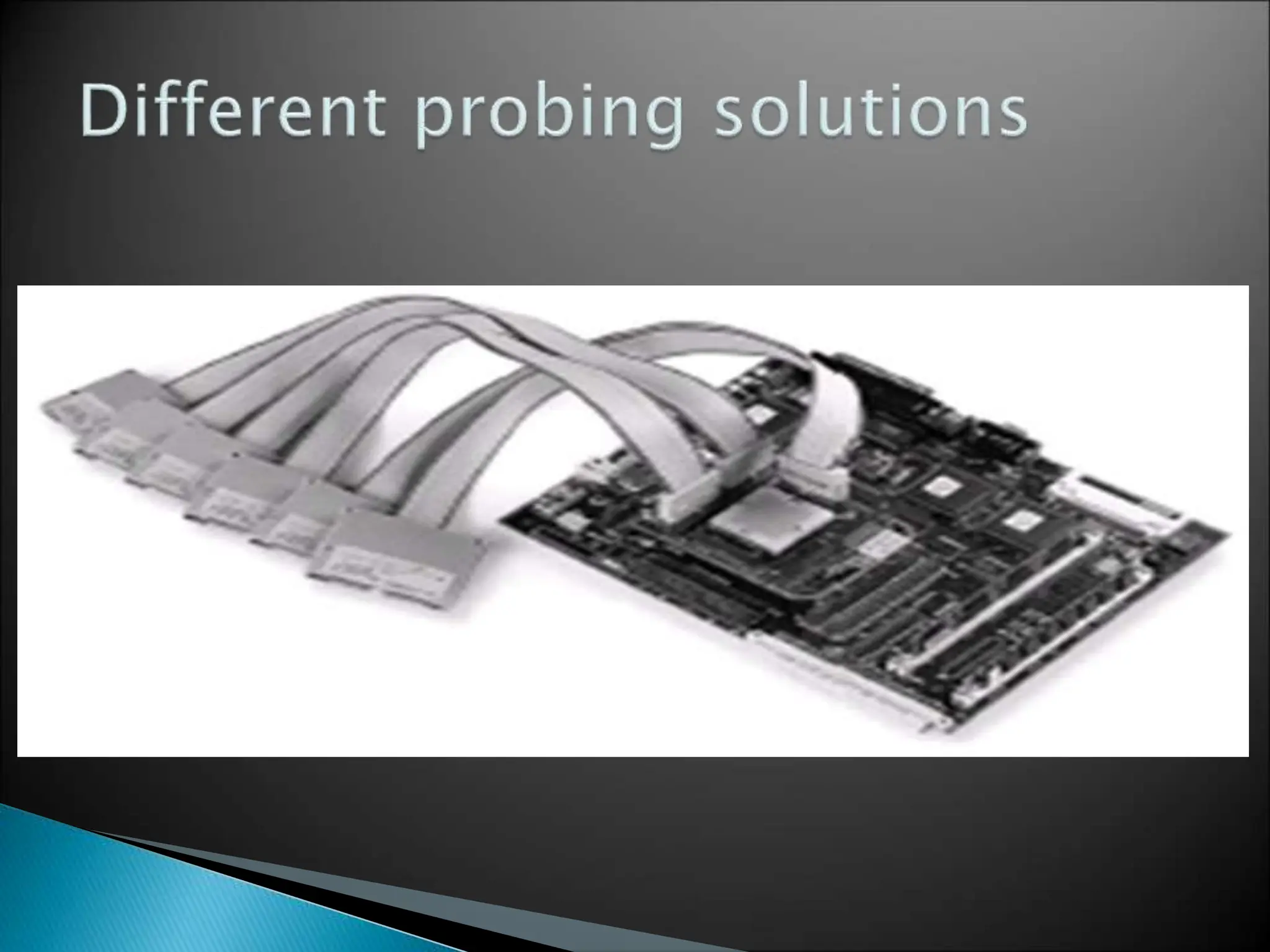

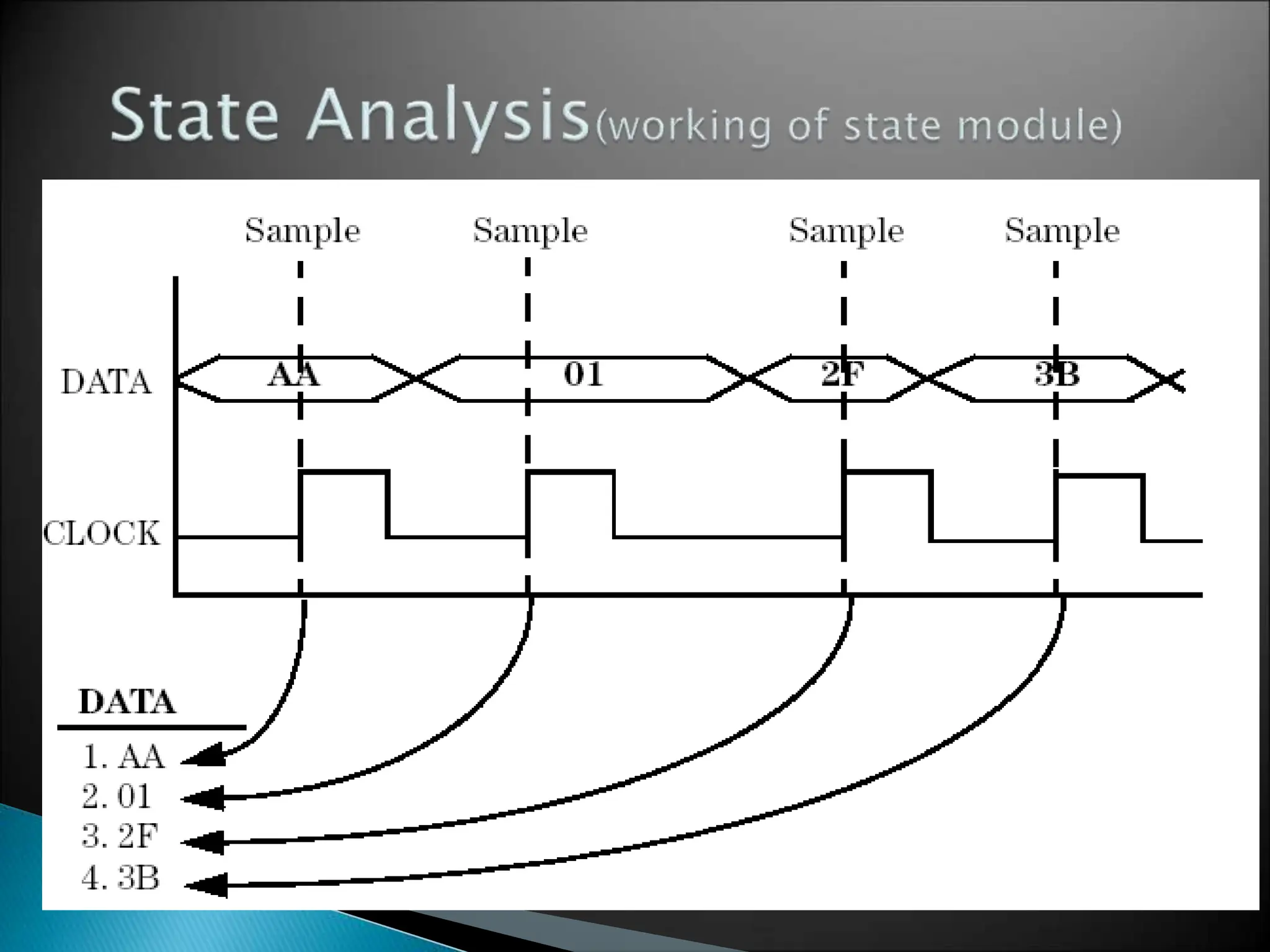

- In-circuit testers and logic analyzers for debugging logic problems.

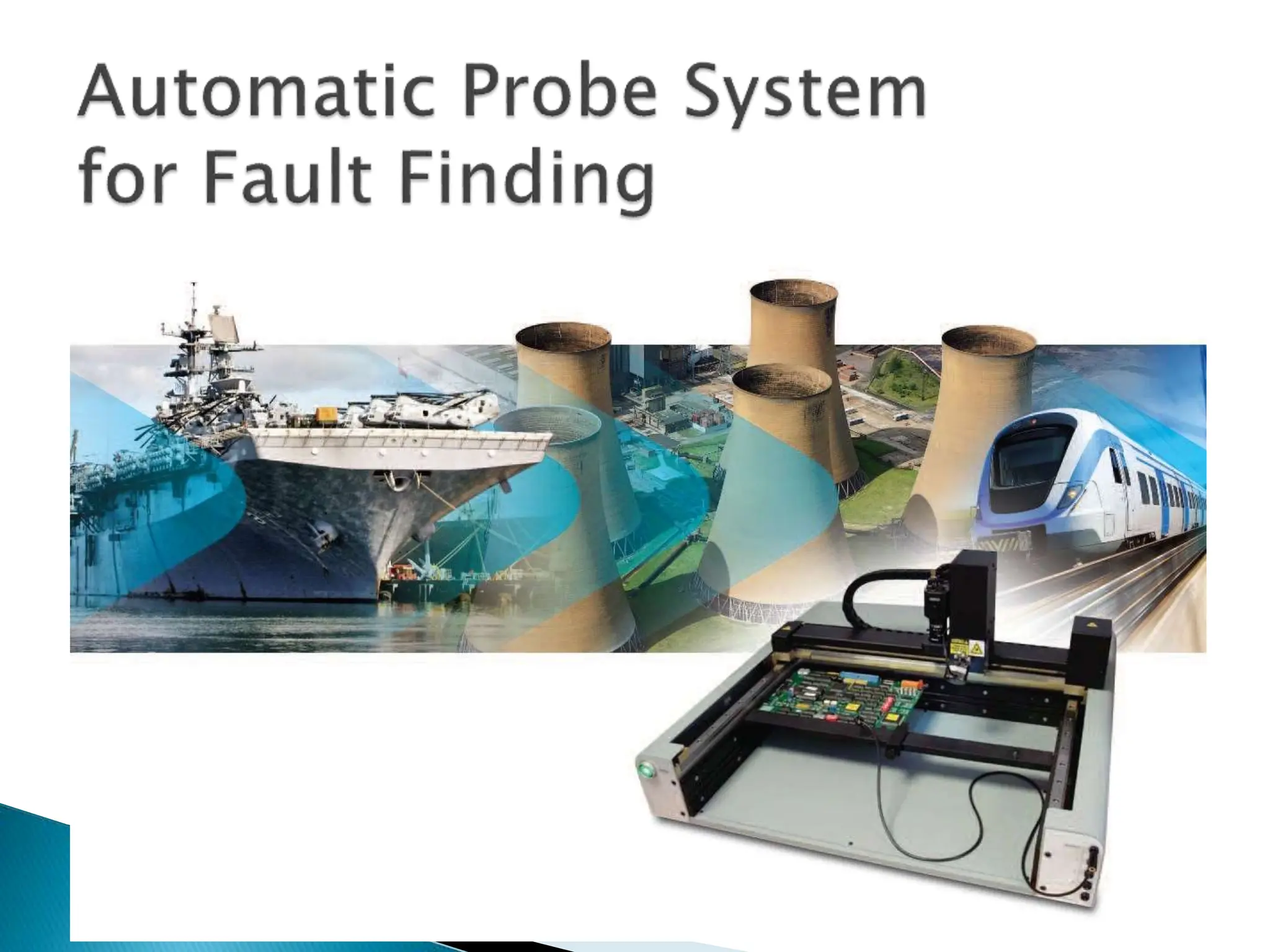

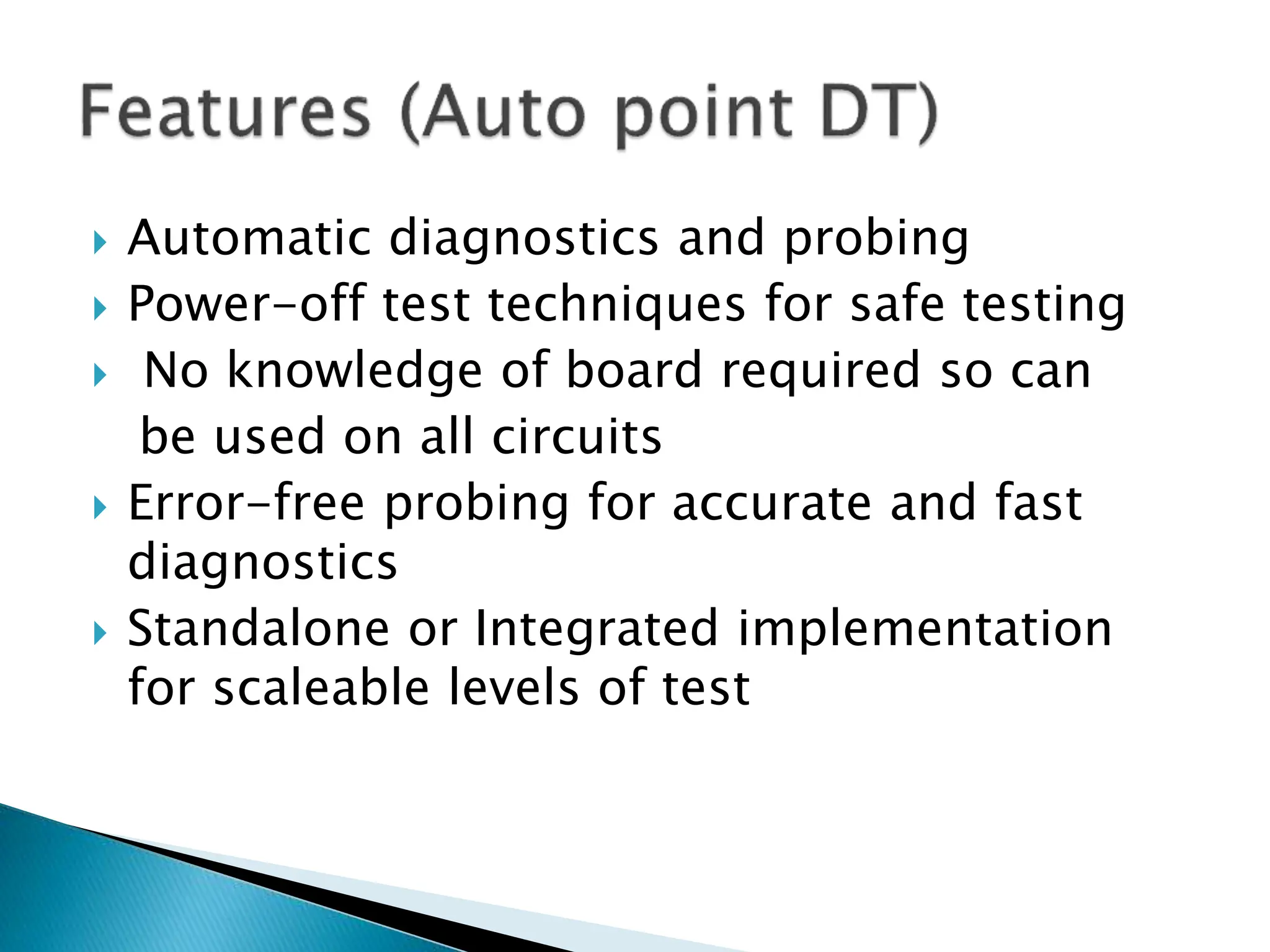

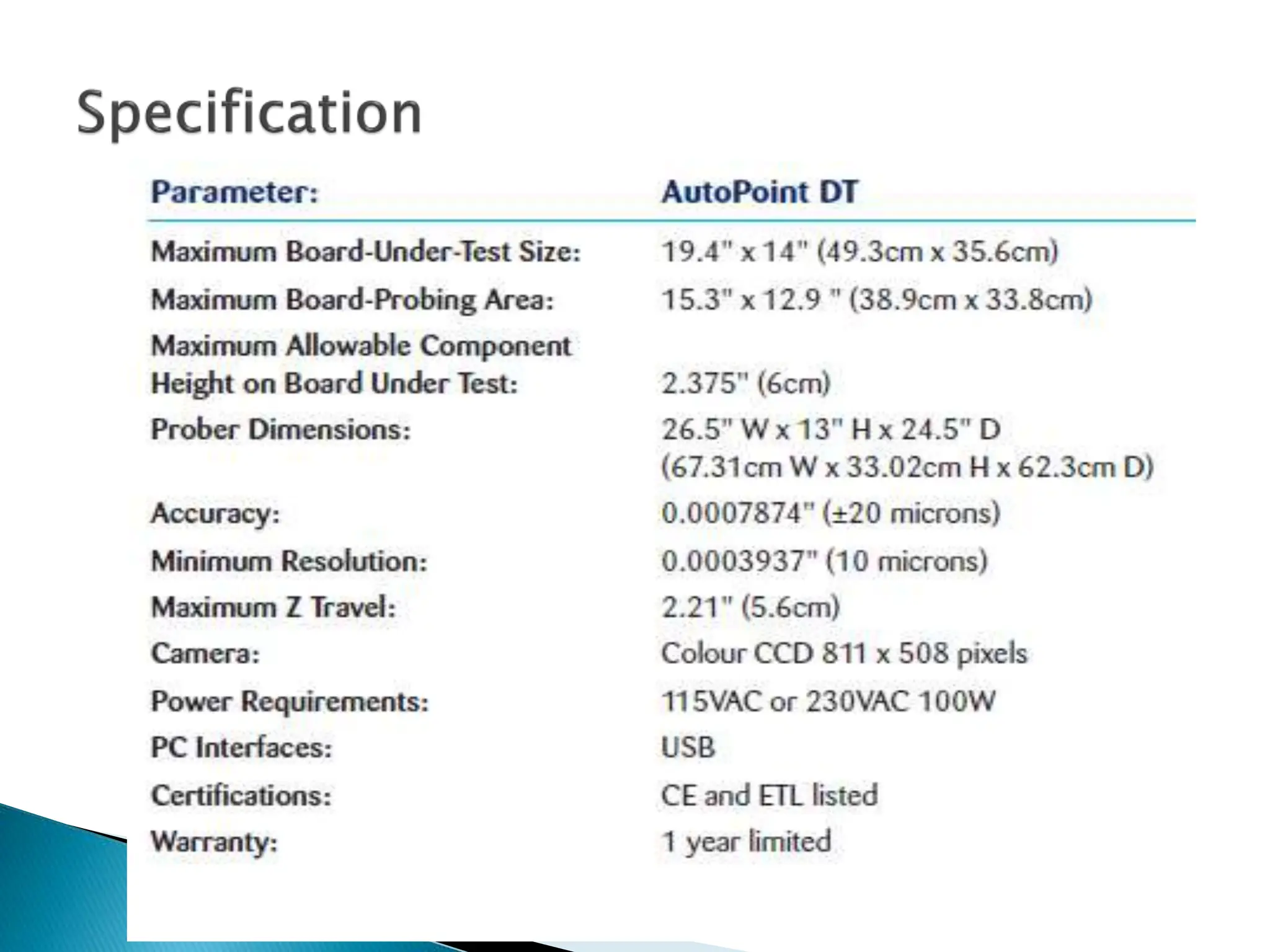

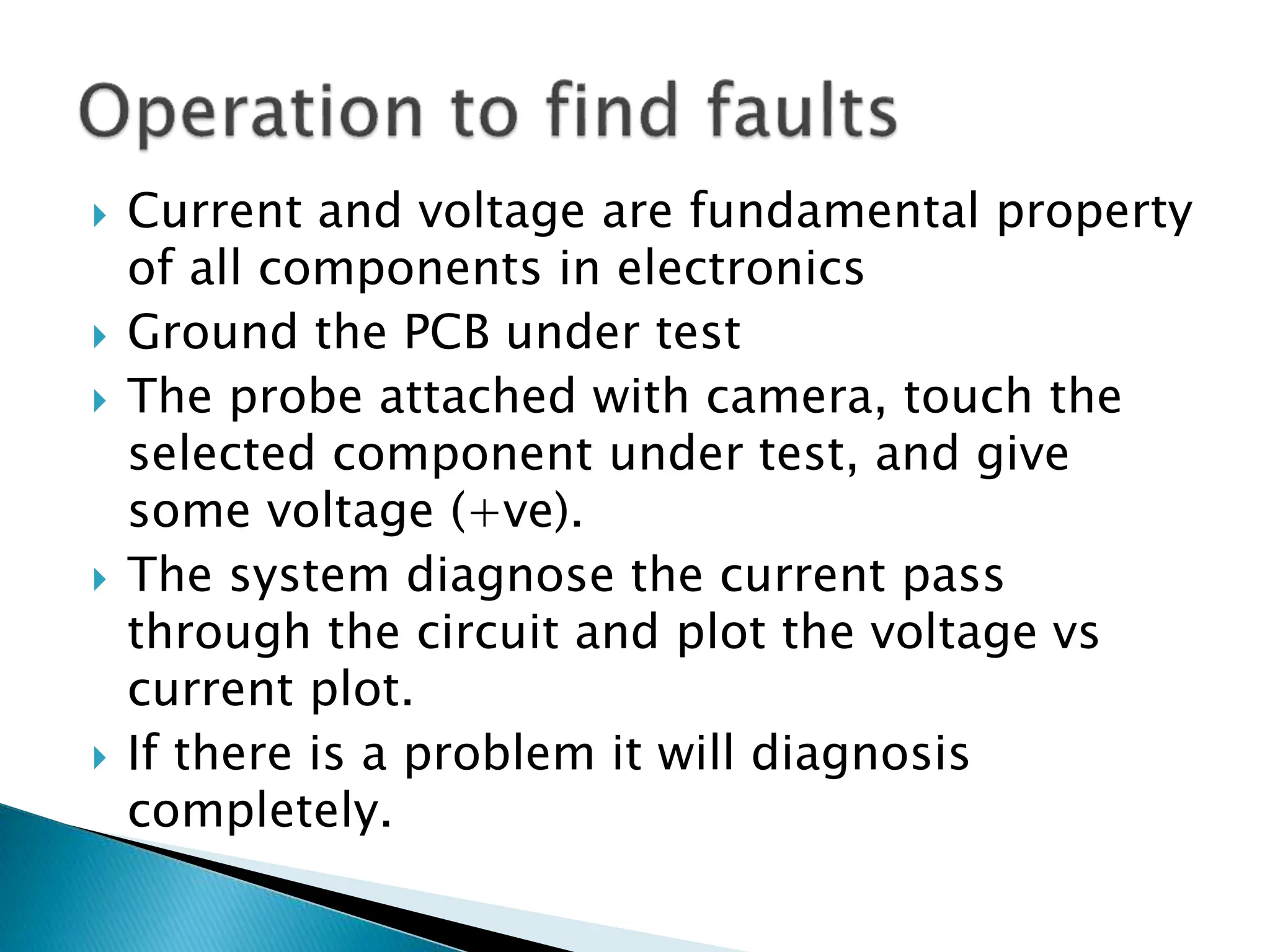

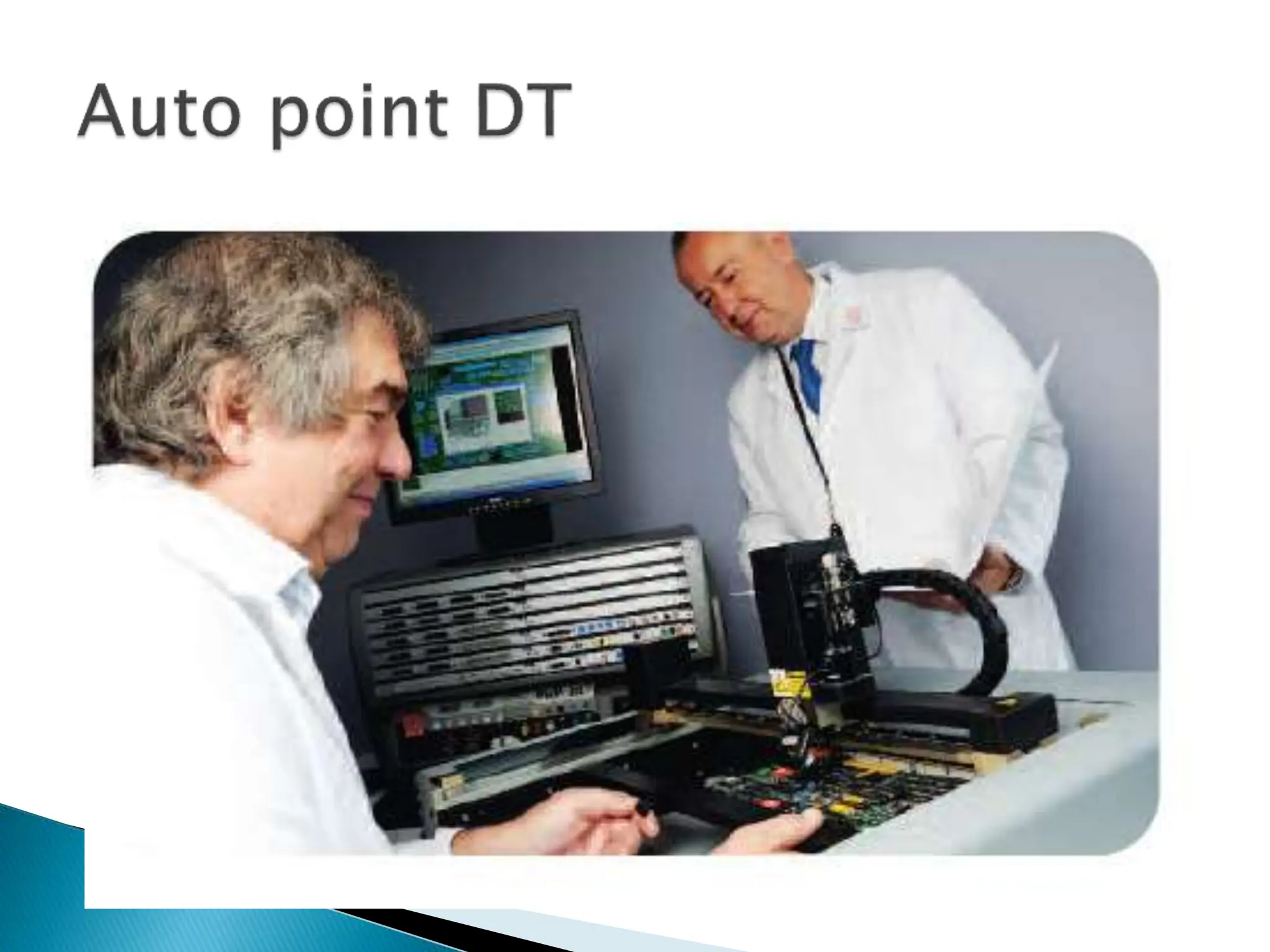

- Advanced techniques like pinpoint technology and auto-point DT for reverse engineering and fault isolation without schematics.

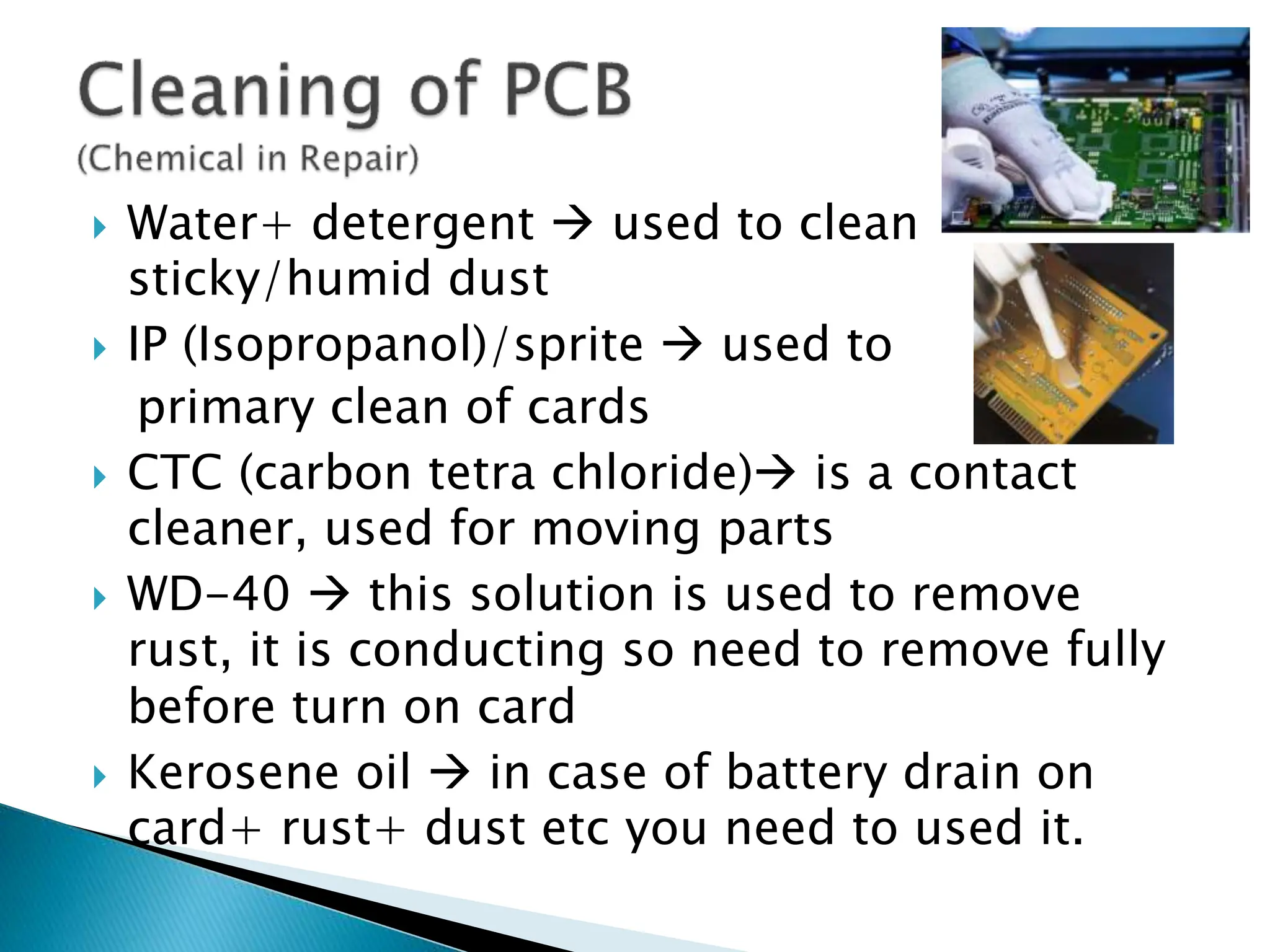

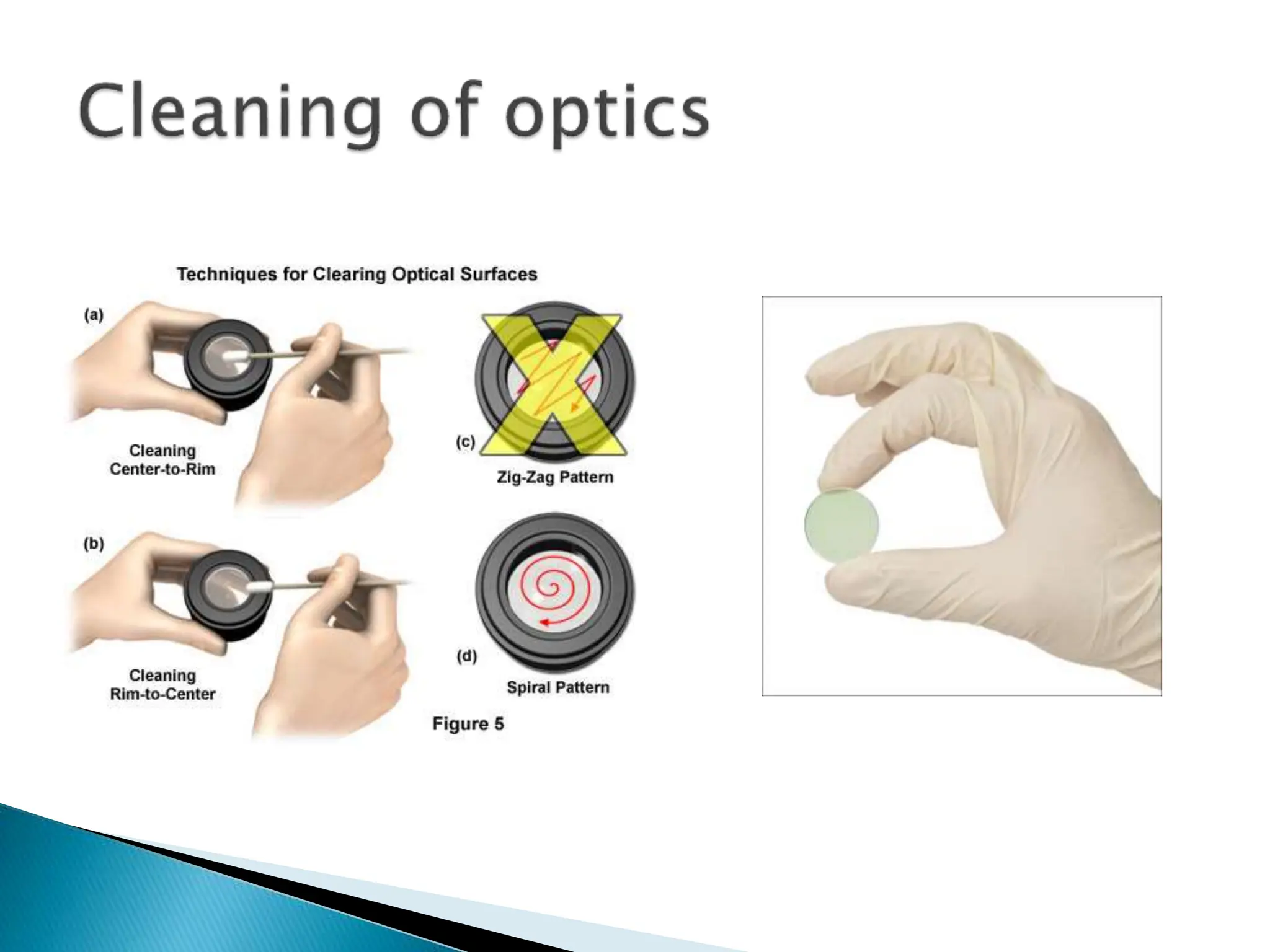

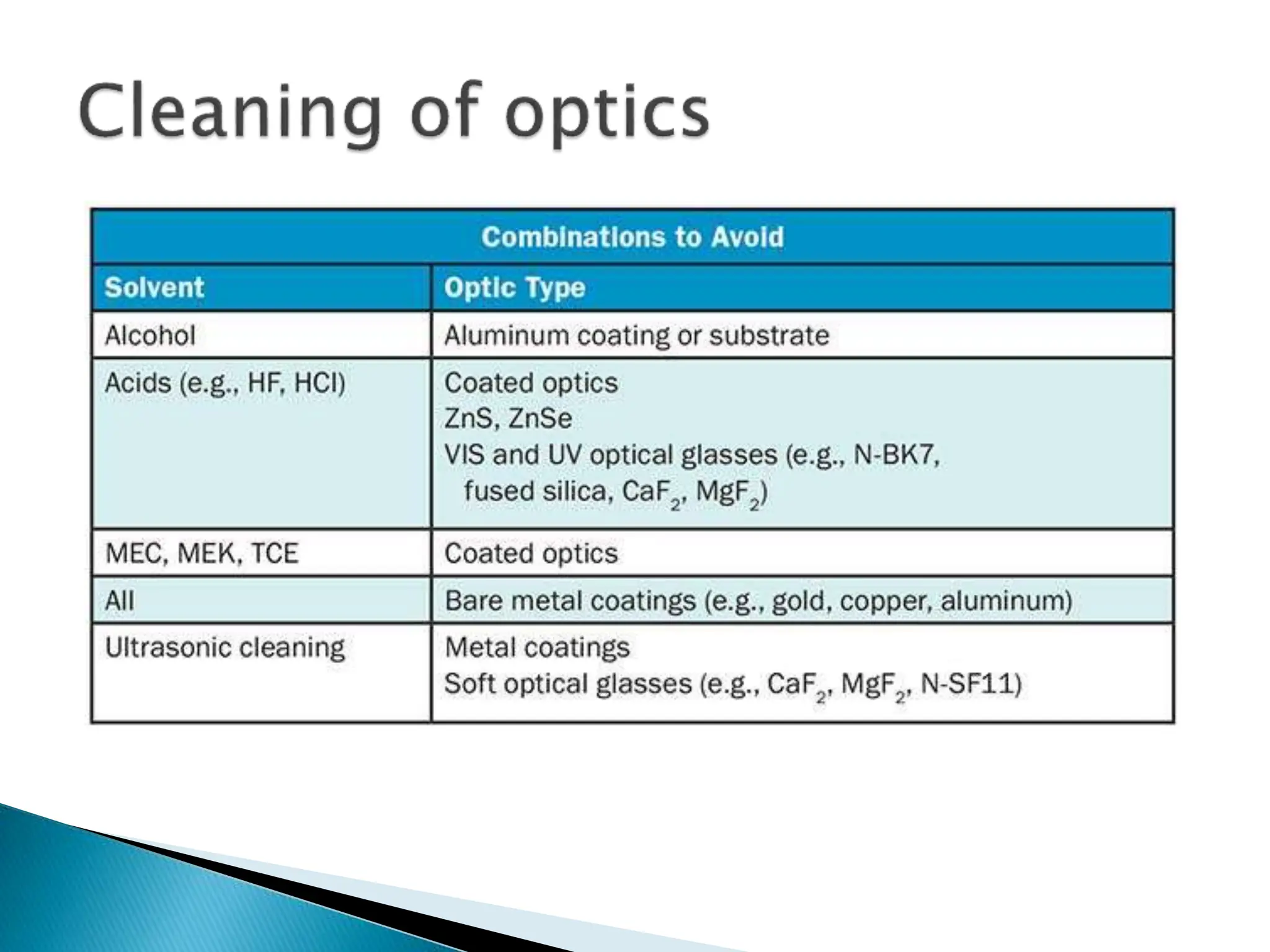

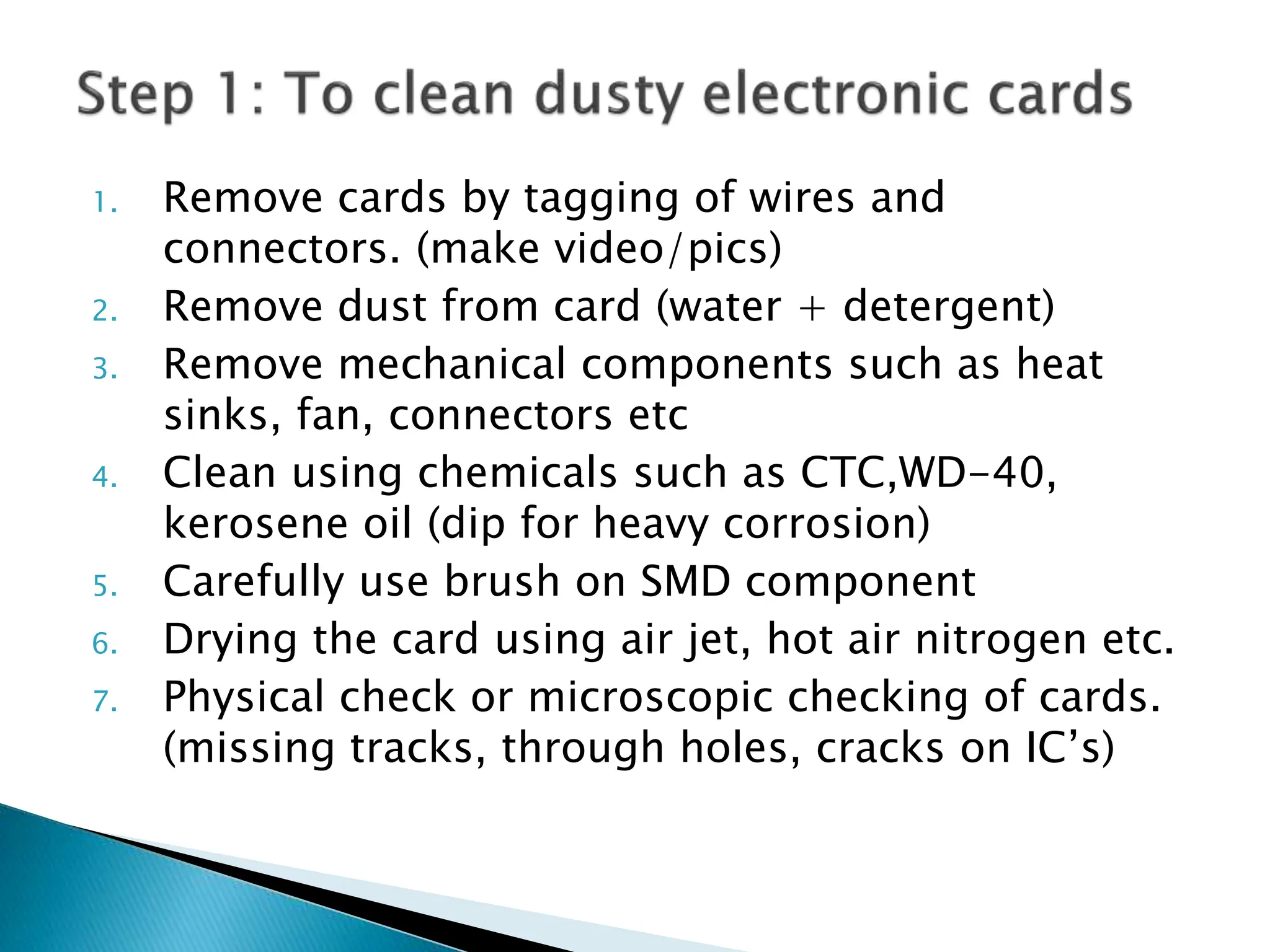

- Considerations for cleaning and maintenance of circuit boards.