This document describes the making of a partial discharge (PD) data acquisition system based on a National Instruments USB digitizer (NI-5133). The system was developed to measure PDs in insulation systems and present the data graphically using phase resolved analysis. Hardware choices and software development in LabVIEW are discussed. The acquisition system was tested using artificially generated pulses and compared to measurements from a Haefley PD568 system.

![1 Background

Measurement and analysis of partial discharge (PD) is an essential tool for

diagnosis of insulation condition [1]. As the High voltage devices ages, the

insulation tends to become weak which could lead to breakdowns due to

various phenomenon occurring inside the device, raising the risk of insulation

failure, which could be disastrous. Thus it becomes imperative to have a

system that enables analysis of potential insulation problems so that the

devices may be repaired or replaced well in advance.

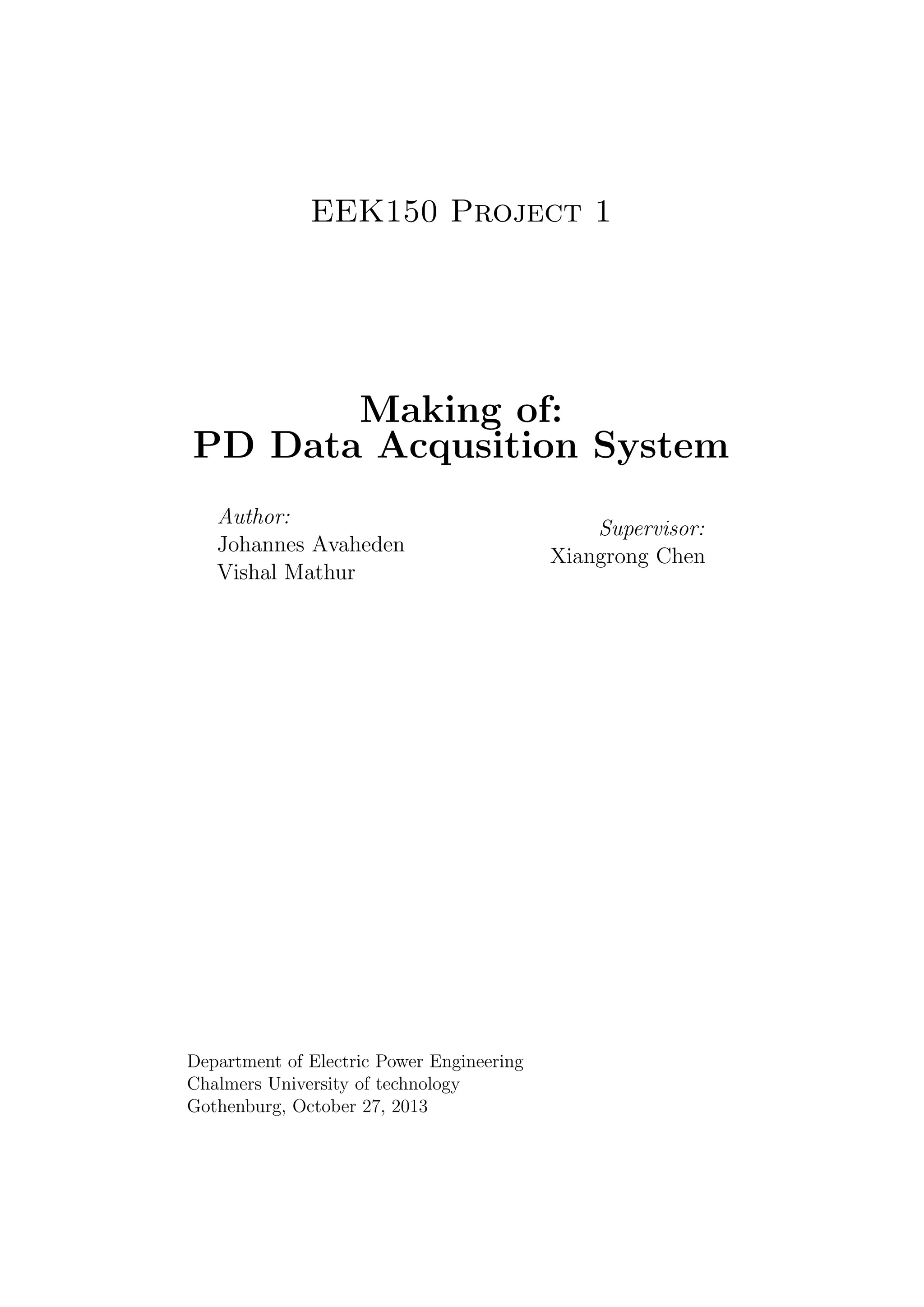

To analyze the PD’s the magnitude of discharge is measured. Furthermore

the phase position (ϕ) when the discharge takes place during the sinosoidal

voltage period is measured. When the PD magnitude (q) is plotted against

the phase angle the PD pattern is obtained. This pattern is what characterise

a certain type of partial discharge. Traditionally this is done with an analog

PD pattern analyzer but as most modern systems today usually run digitally,

a way to analyze PD patterns digitally is therefore desirable.

2 Aim of the project

The Aim of the project is to develop a portable, digital system for partial

discharge acquisition using an analogue input from hardware such as Haefely

PD568.

1](https://image.slidesharecdn.com/ddf507b9-387c-4e9a-b3a6-8e8cda597dcf-150907103754-lva1-app6891/85/Making-of-a-PD-Data-Acqusition-System-5-320.jpg)

![5.0.1 Phase resolved analysis

Analysis based on phase resolved technique depicts the type of defect and

the level of insulation degradation reached. This is done with the help of

analyzing the discharge occurrence pattern over the power line sinusoidal

wave. This type of distribution is known as the ”fingerprint of a discharge”.

This plays an important role in identifying the kind of defect present in

insulation and the level of deterioration. A typical PD-pattern is presented

in Figure 2.

Figure 2: A typical PD-pattern recieved with the phase resolve method [1]

5](https://image.slidesharecdn.com/ddf507b9-387c-4e9a-b3a6-8e8cda597dcf-150907103754-lva1-app6891/85/Making-of-a-PD-Data-Acqusition-System-9-320.jpg)

![6 Method

The development was divided into two parts. First proper hardware were to

be chosen. Second the software to run the hardware were to be developed.

6.1 Choice of Hardware

As explained in Section 3, the digital PD-acquisition system needs to have

the capability to sample and store data to characterize PD’s. It should also

be capable of transferring the data obtained to the host PC’s random access

memory to generate (ϕ, q) plots.

NI USB- 5133 digitizer fulfills all the needs required for this system.

Figure 3: The NI USB-5133 digitizer [2]

The main factors that were considered while selecting digitizer were the

sampling rate, which for the USB-5133 is 100 MS/s. That assures a truthful

reproduction of the analog signal to digital. The bandwidth of 50 MHz and

2 simultaneously sampled channels with 8-bit resolution makes it an ideal

choice. It is having 8 Mb memory equally divided between two channels

CH1 and CH2. The bus powered, plug and play feature of this device makes

it portable and easy to use.

As presented in Figure 1, the USB digitizer would be connected to the the

synchronizing port of the quadripole via channel CH0 or CH1. The digitizer

is having an operating voltage range of 40 Vp−p, i.e. from -20V to +20V. In

6](https://image.slidesharecdn.com/ddf507b9-387c-4e9a-b3a6-8e8cda597dcf-150907103754-lva1-app6891/85/Making-of-a-PD-Data-Acqusition-System-10-320.jpg)

![References

[1] J.A. Ardila-Rey et. al. A Partial Discharges Acquisition and Statistical

Analysis Software. 2012.

[2] url: http://sine.ni.com/nips/cds/view/p/lang/sv/nid/203720.

22](https://image.slidesharecdn.com/ddf507b9-387c-4e9a-b3a6-8e8cda597dcf-150907103754-lva1-app6891/85/Making-of-a-PD-Data-Acqusition-System-26-320.jpg)