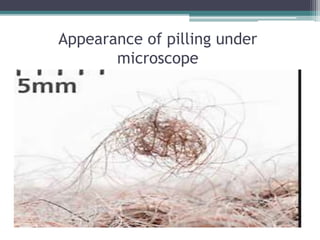

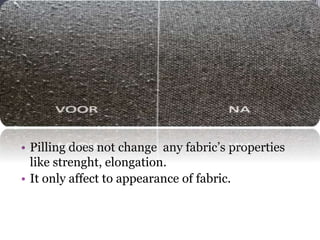

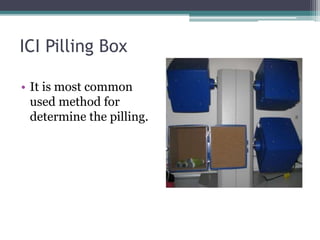

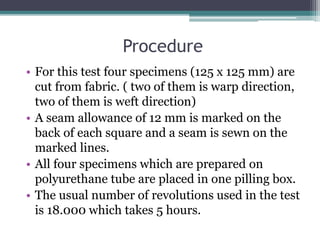

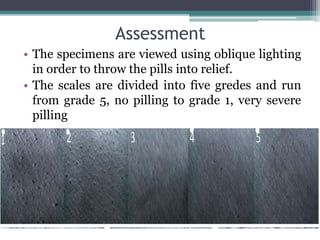

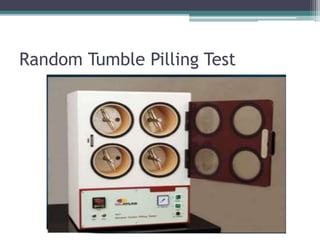

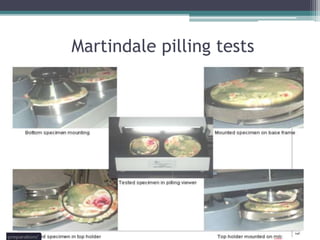

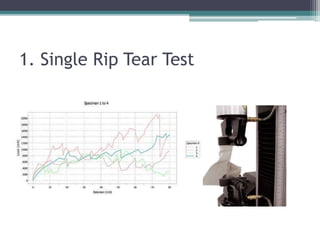

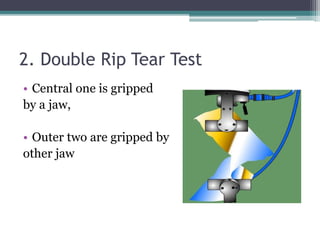

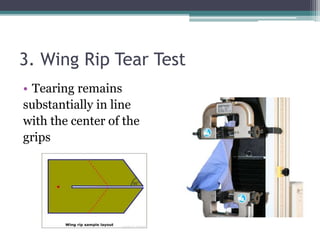

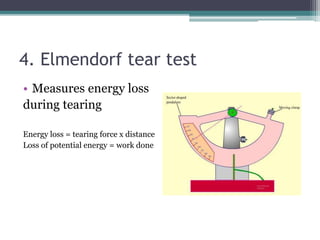

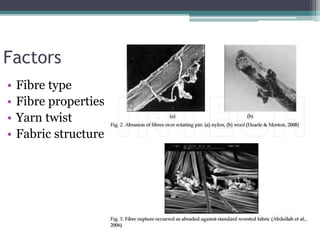

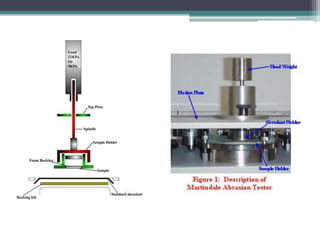

This document discusses methods for determining the performance of woven fabrics, including pilling resistance, abrasion resistance, tear strength, and breaking strength. It describes common tests for each property, such as the ICI pilling box test and Wyzenbeek abrasion test. Pilling is caused by fiber mobility and tangling, and is rated on a scale from 1 to 5. Abrasion resistance depends on fiber type, properties, twist, and fabric structure. Tear and breaking strength measurements use methods like the strip, grab, and rip tests.