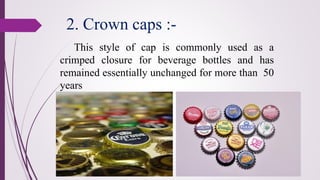

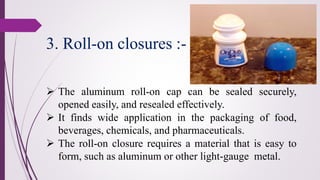

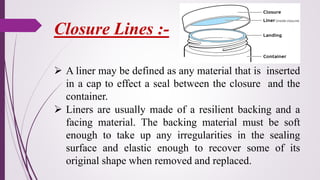

Closures are devices used to seal containers like bottles and jars. They must provide an effective hermetic seal while preventing contents from escaping and external substances from entering. Common closure types include screw caps, crown caps, roll-on closures, and press-on caps. Closure quality is ensured through testing of materials, dimensions, extractables and leachables, bioburden, and sterilization validation. Proper closure selection and quality control ensures container integrity and product safety.