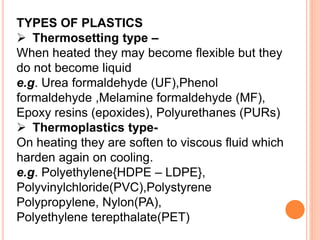

This document discusses various types of packaging materials and containers used for pharmaceuticals. It describes desirable features of pharmaceutical containers including being FDA approved, non-toxic, and protecting the product. The main types of packaging materials discussed are glass, plastic, metal, and rubber. Glass provides protection but is fragile, while plastic is flexible but permeable. Metals are impermeable yet can react with chemicals. The document also outlines different levels of pharmaceutical packaging from primary to tertiary.