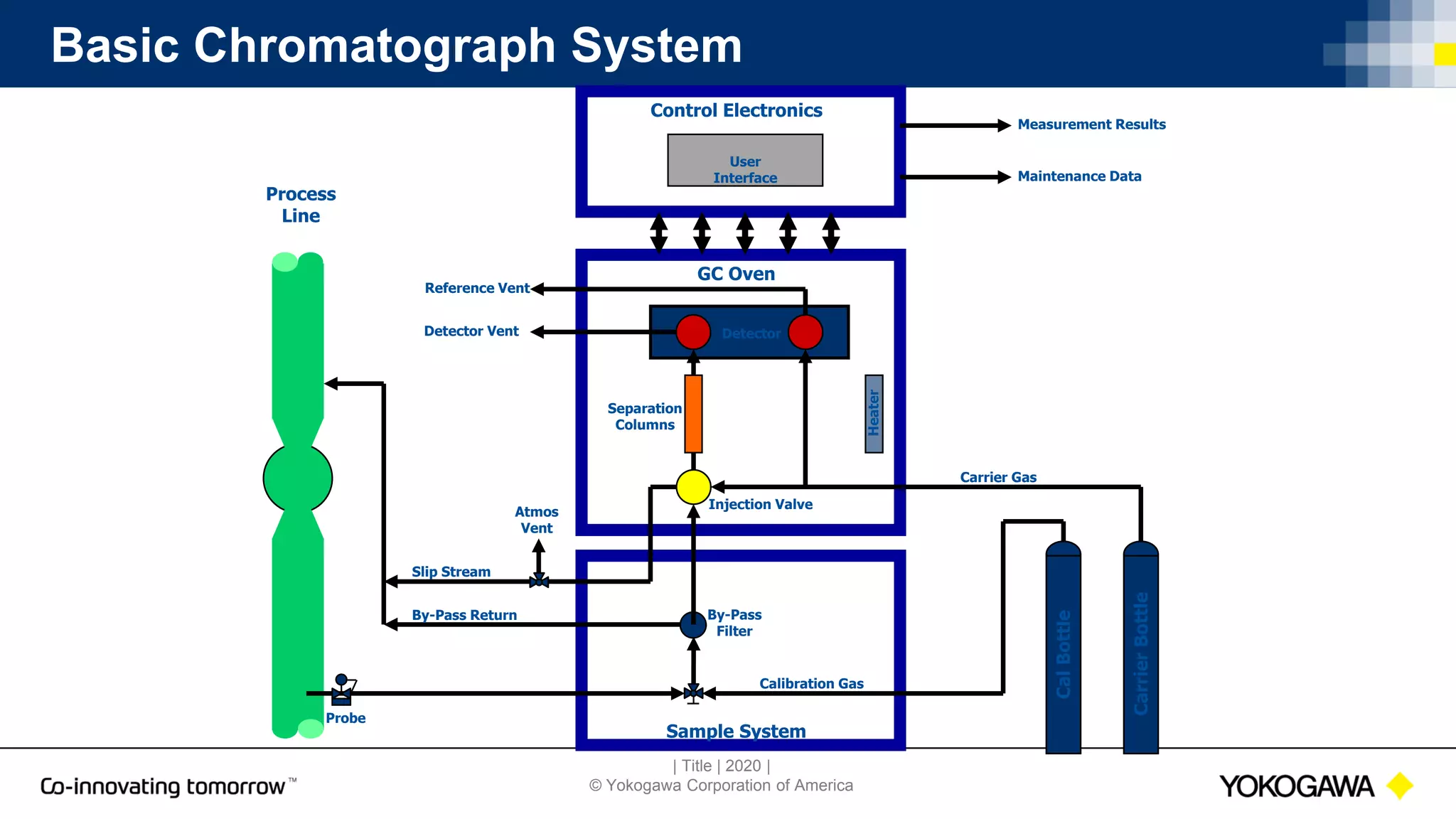

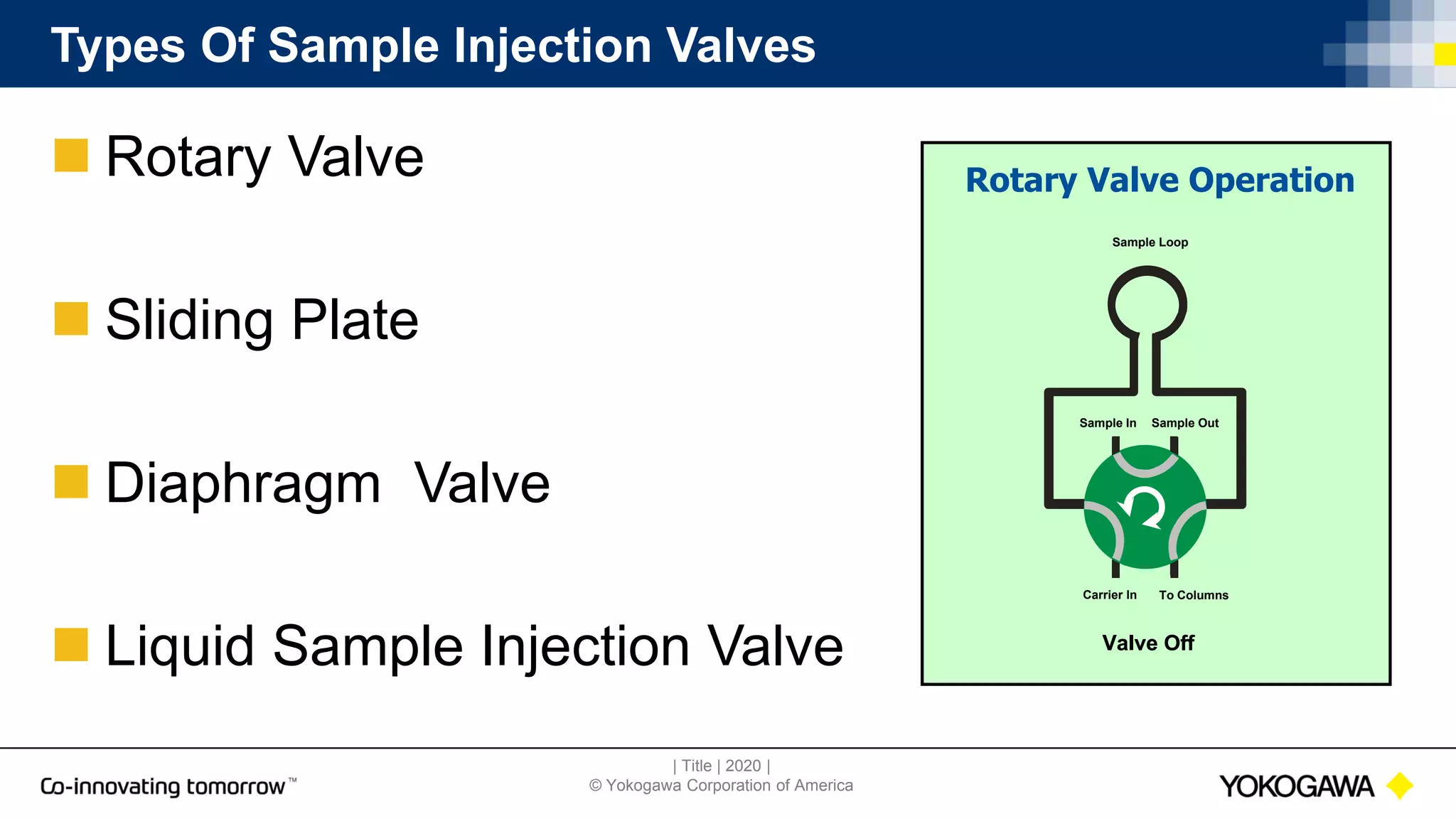

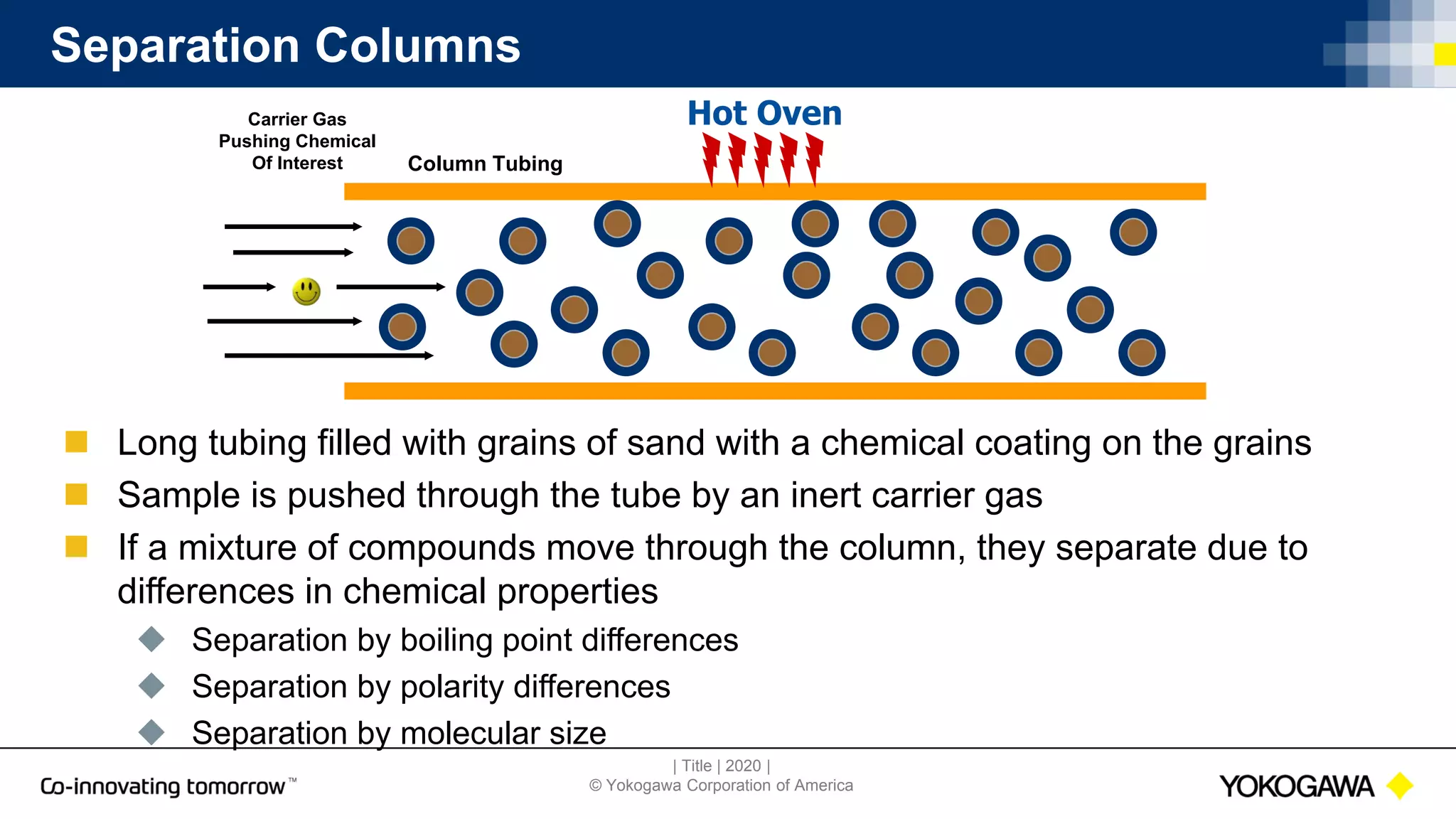

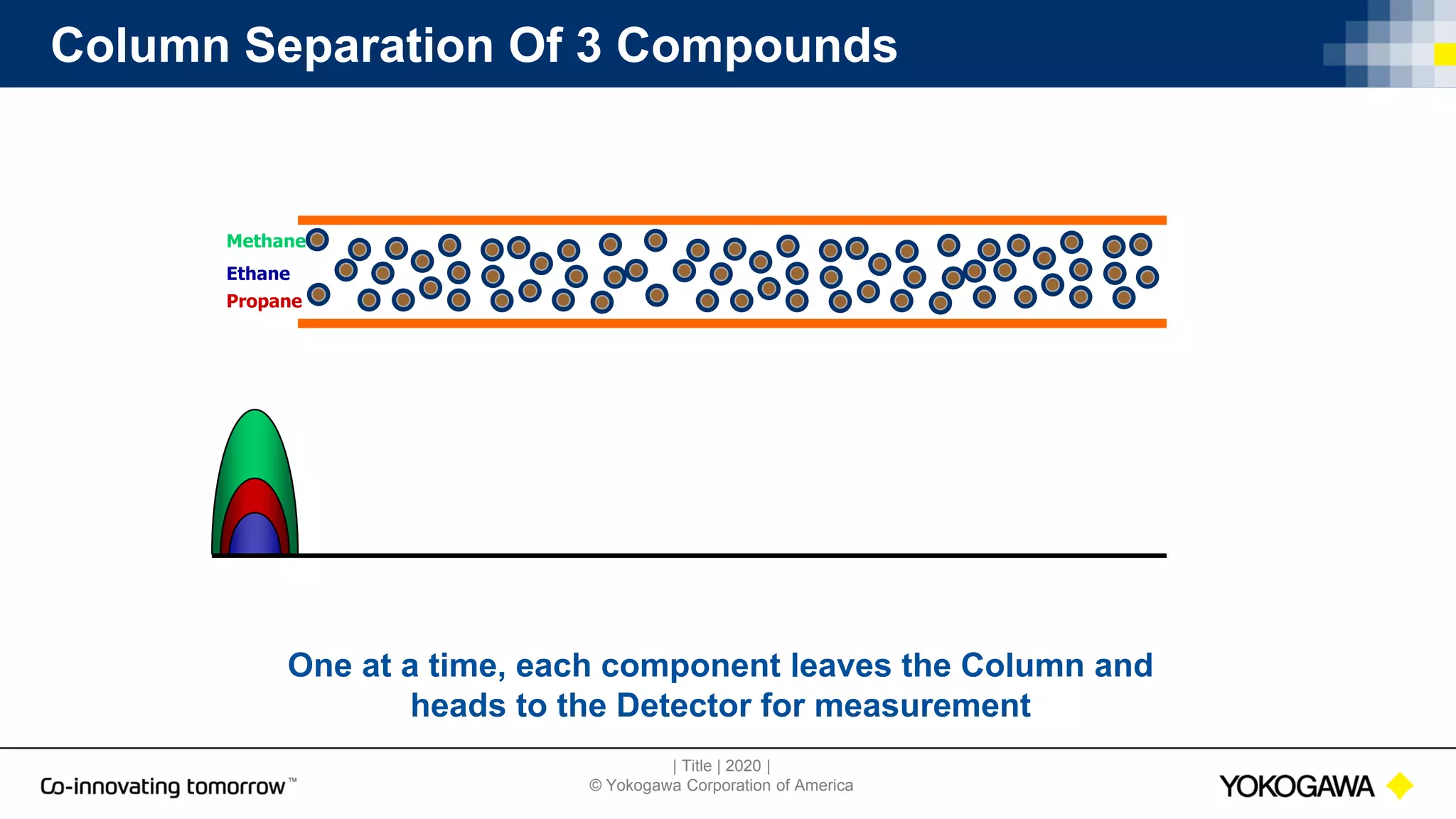

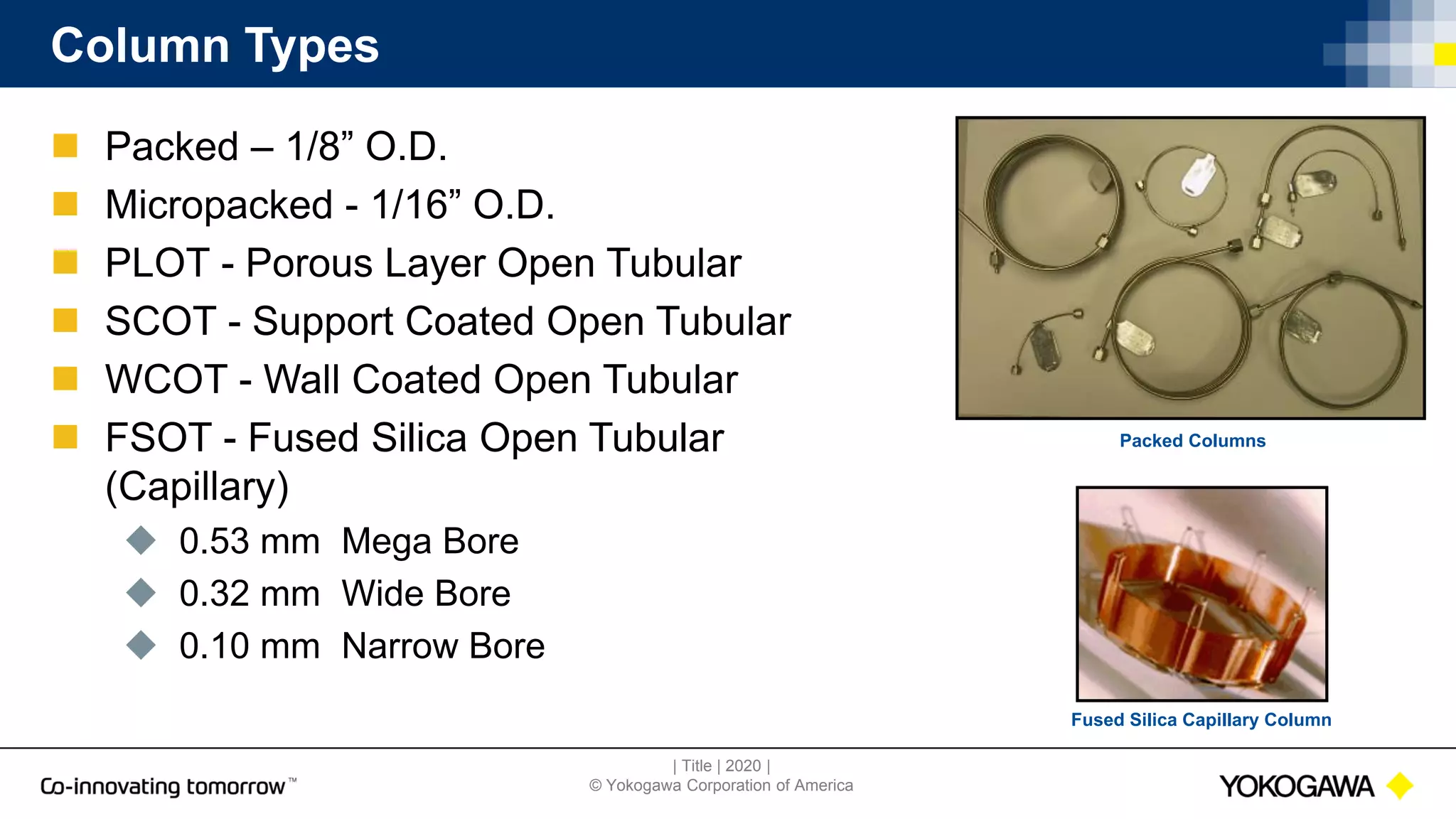

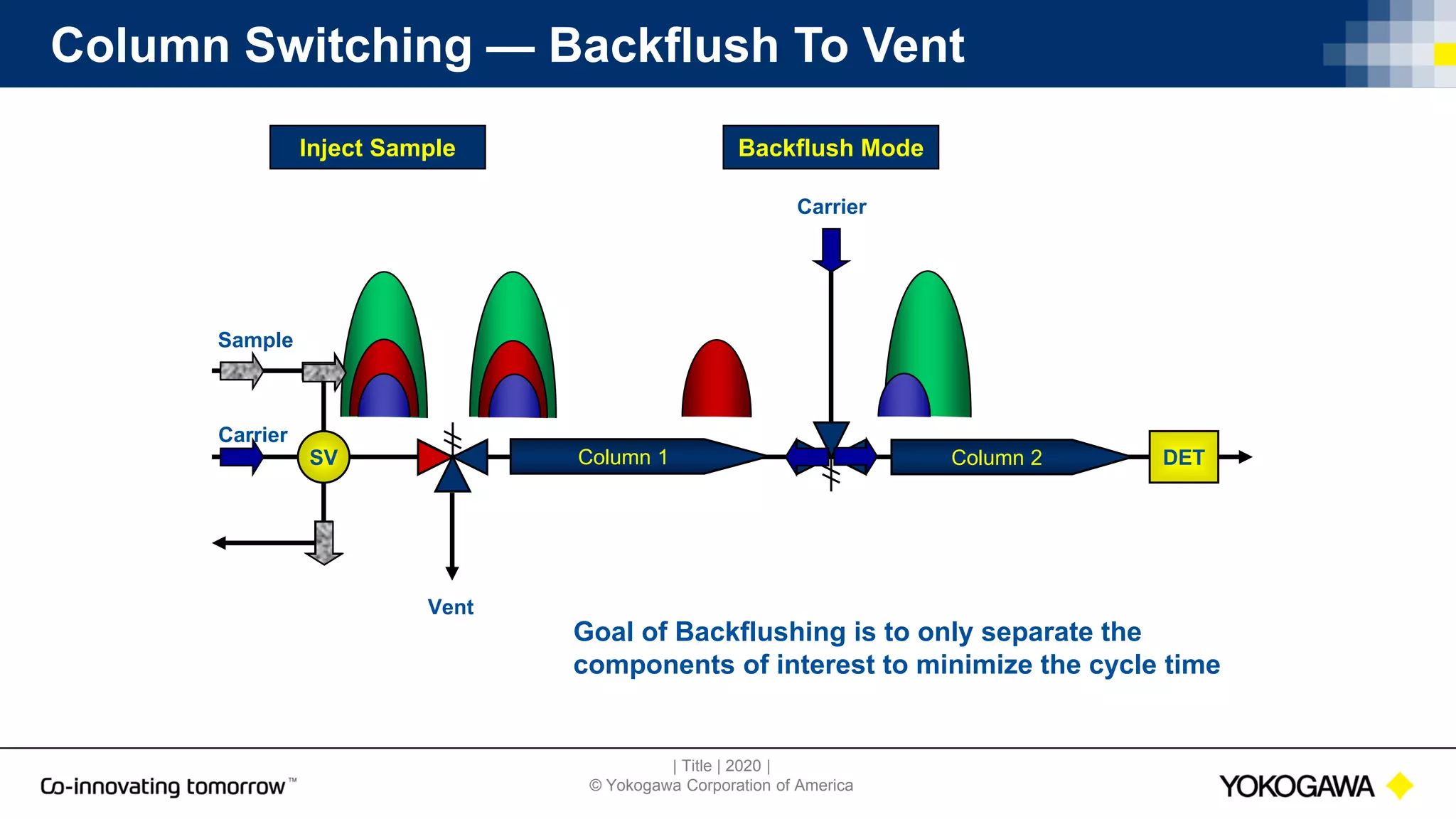

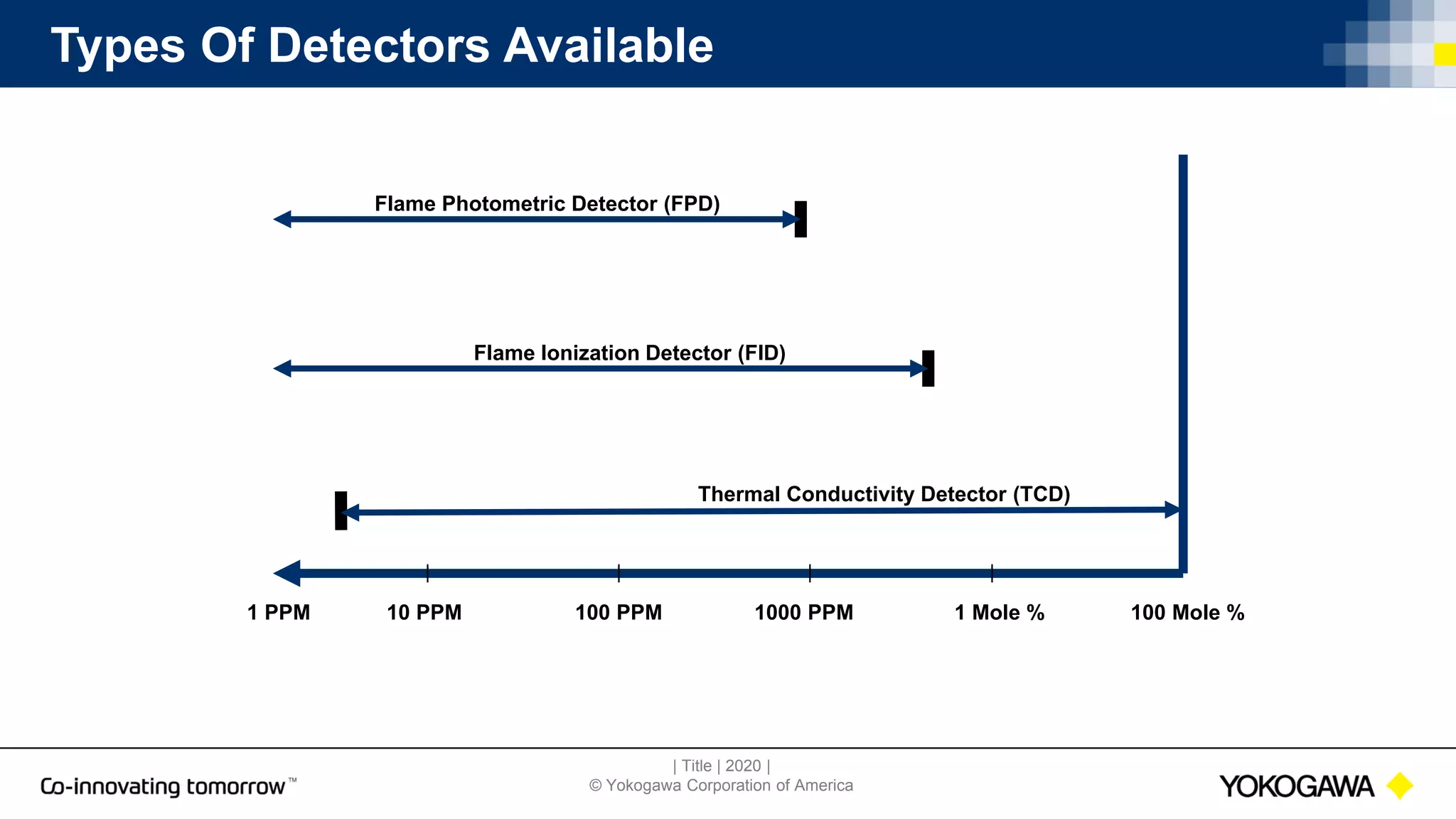

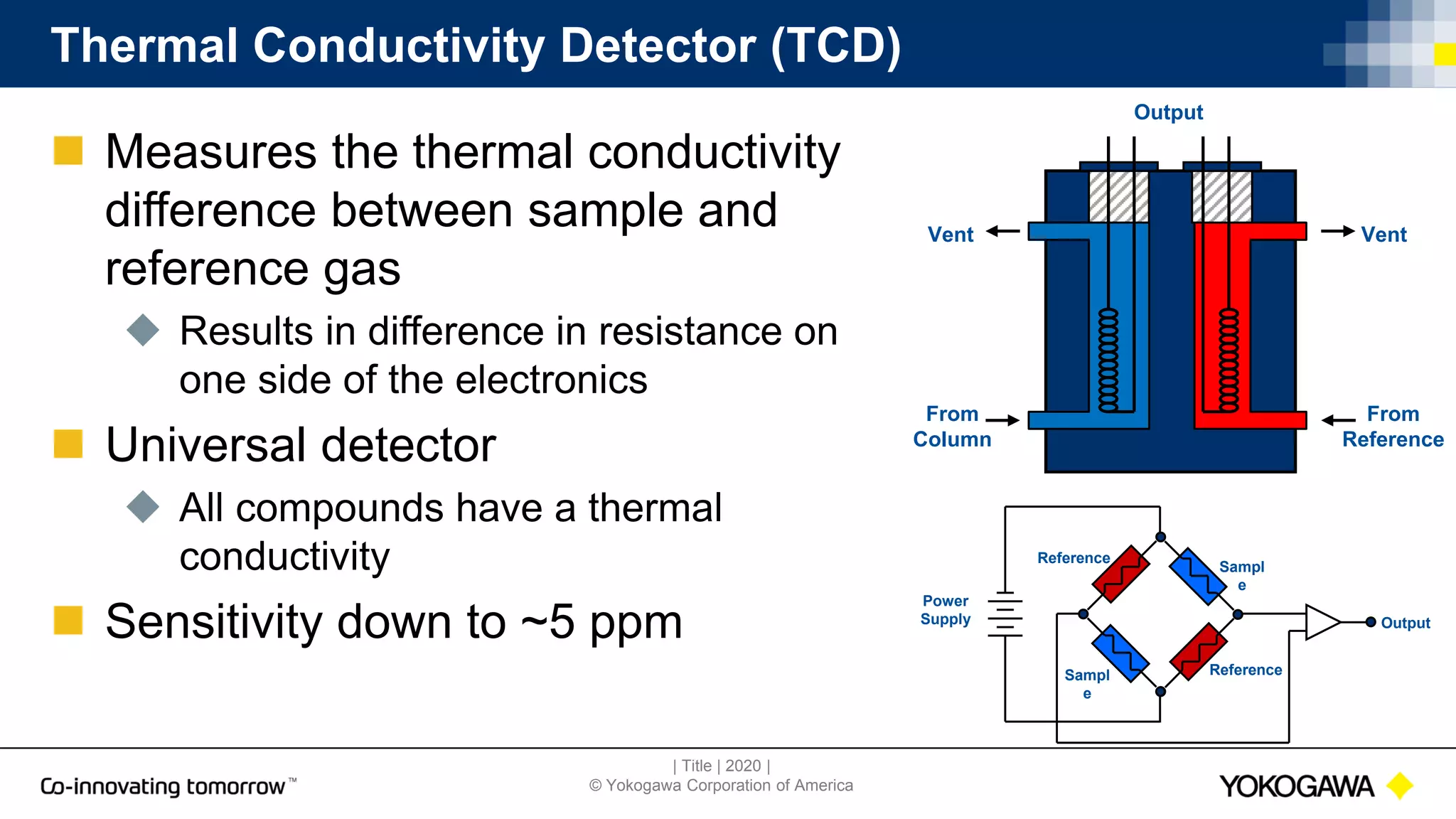

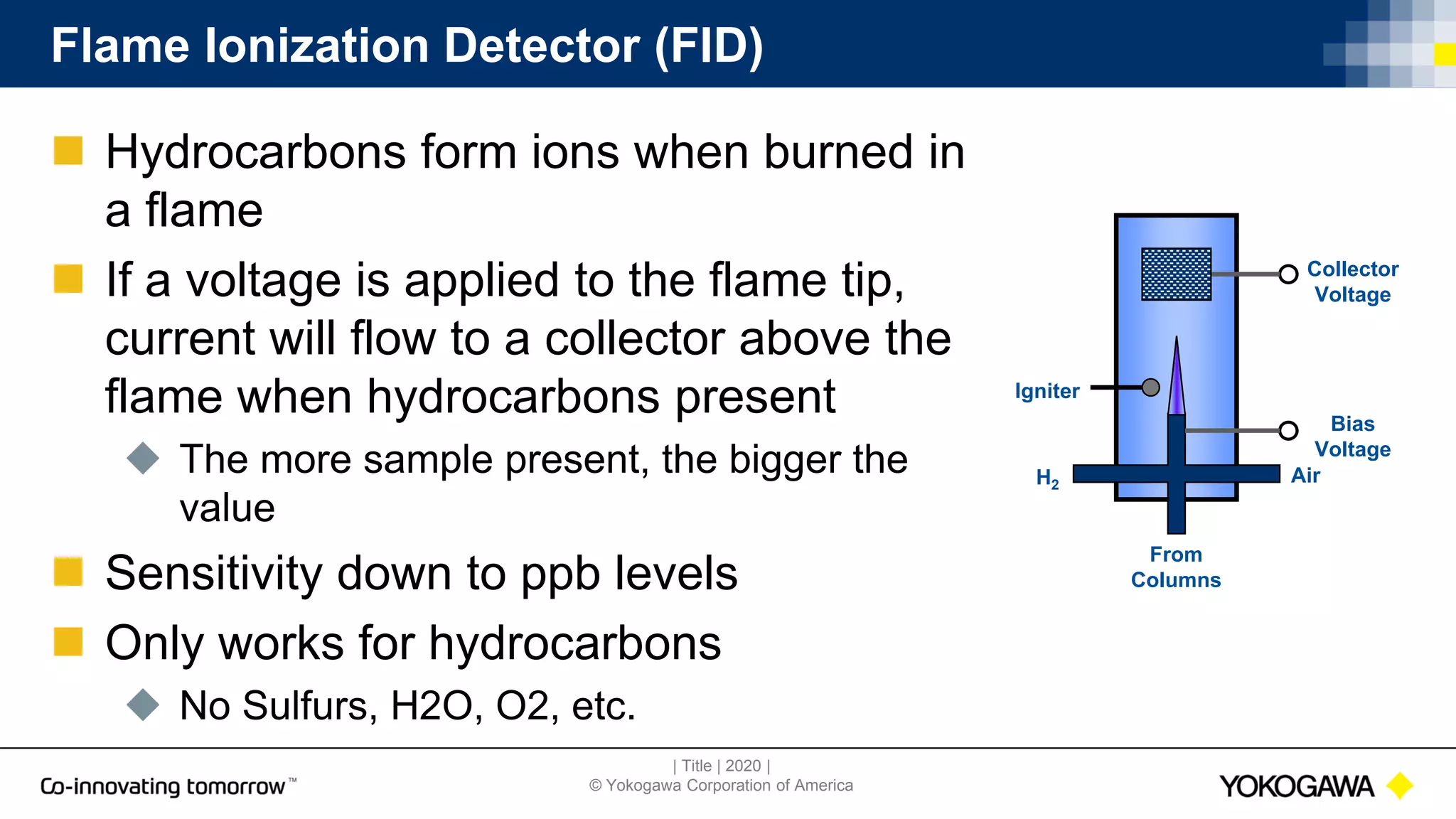

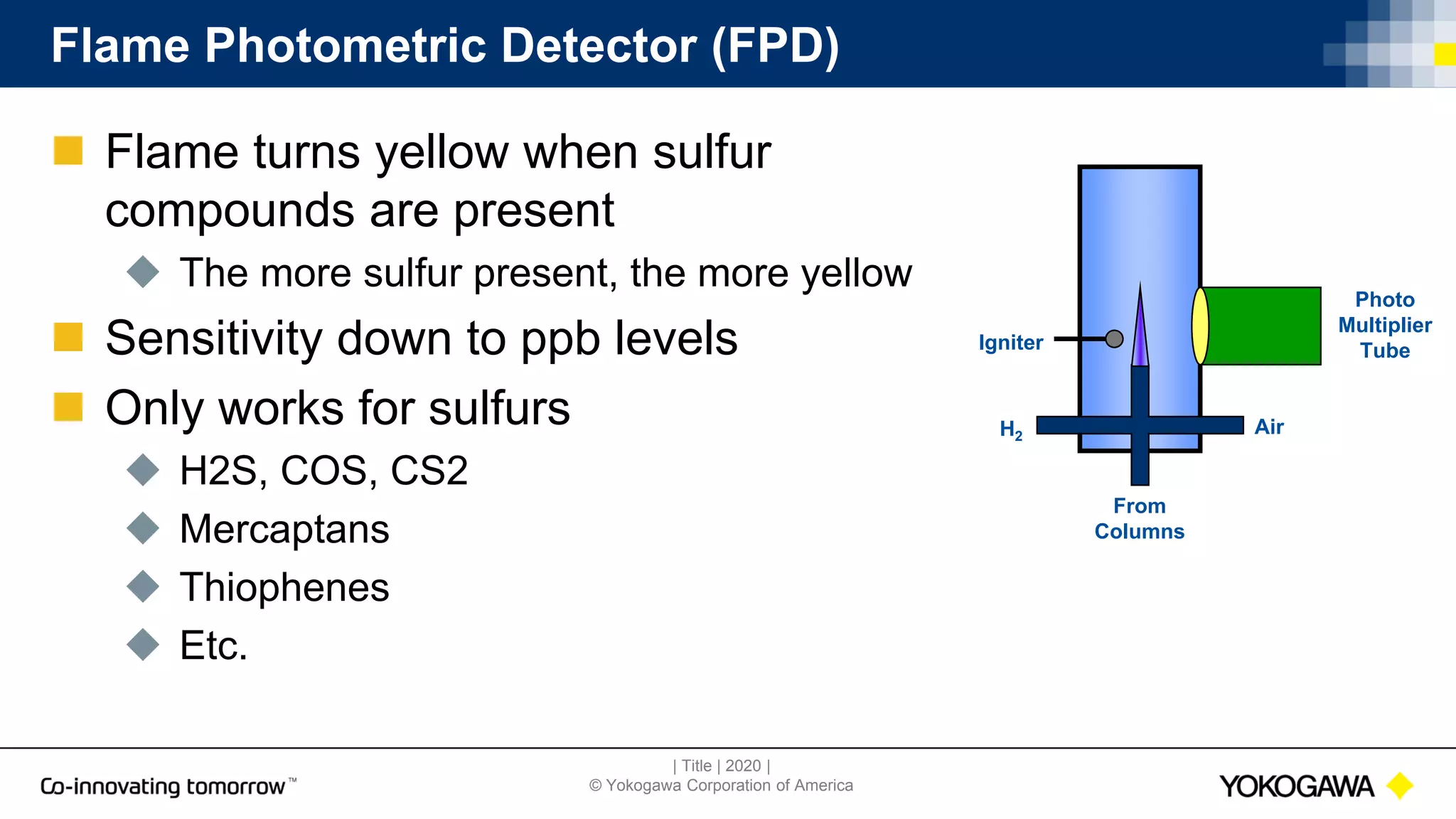

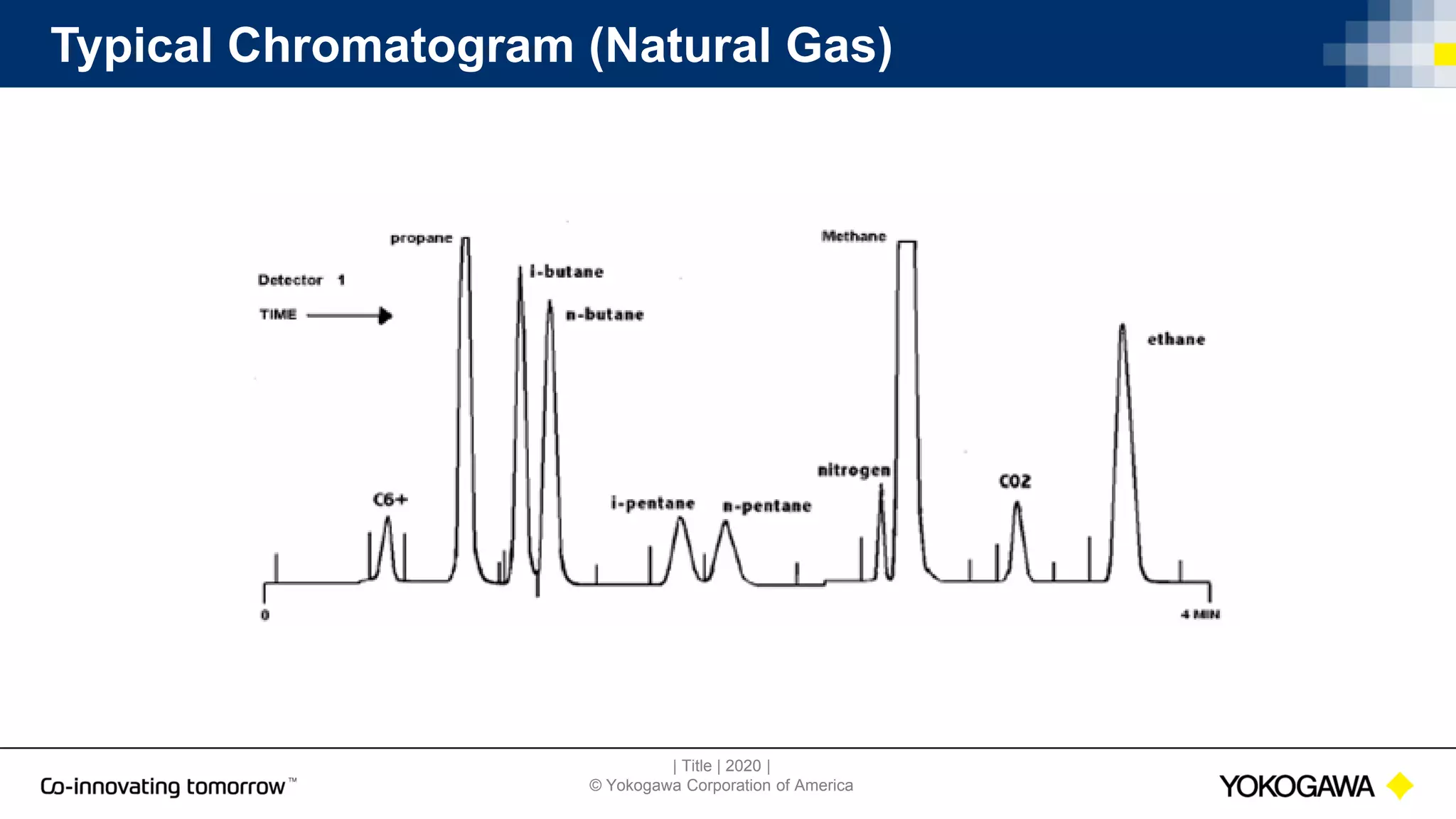

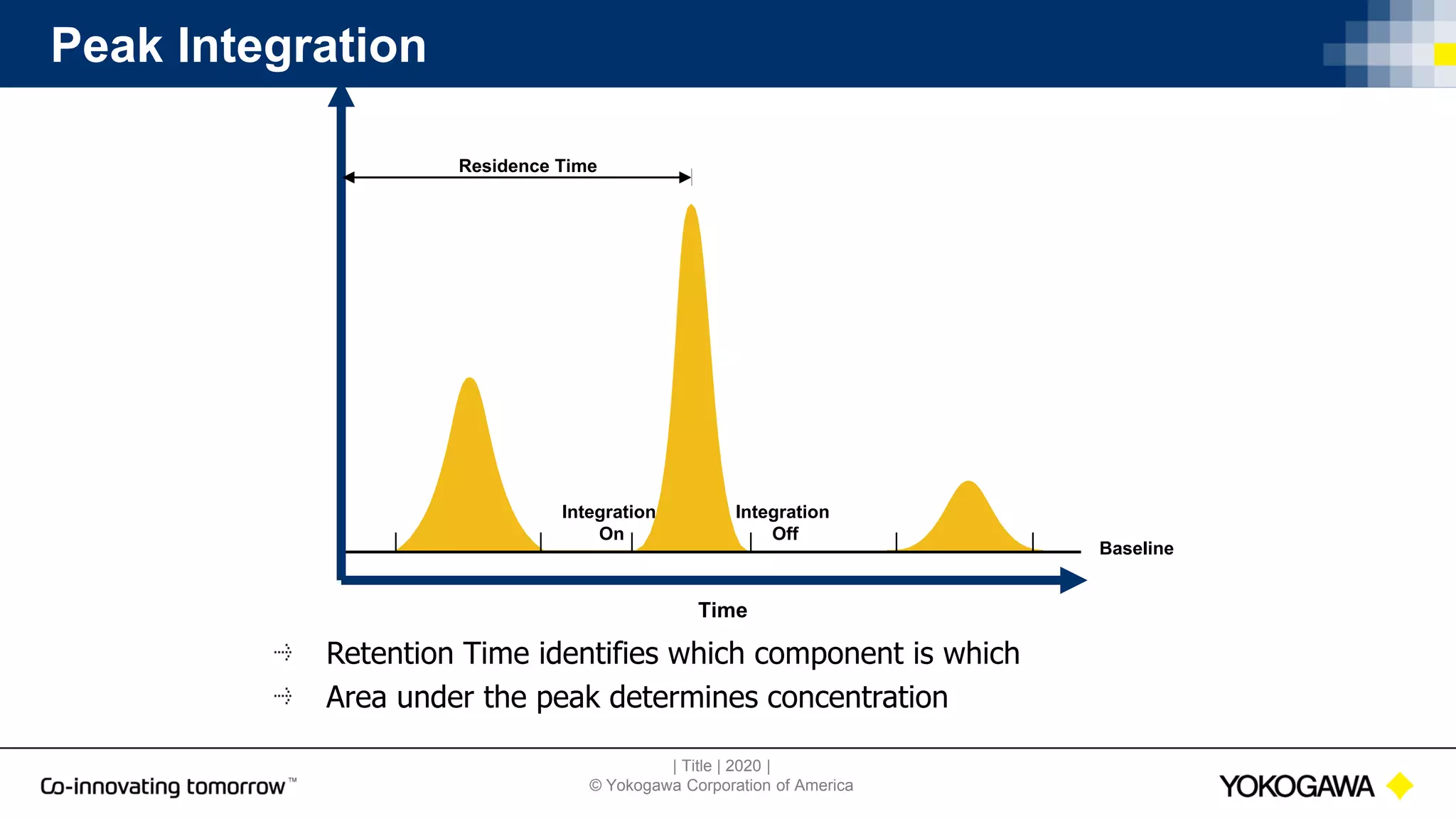

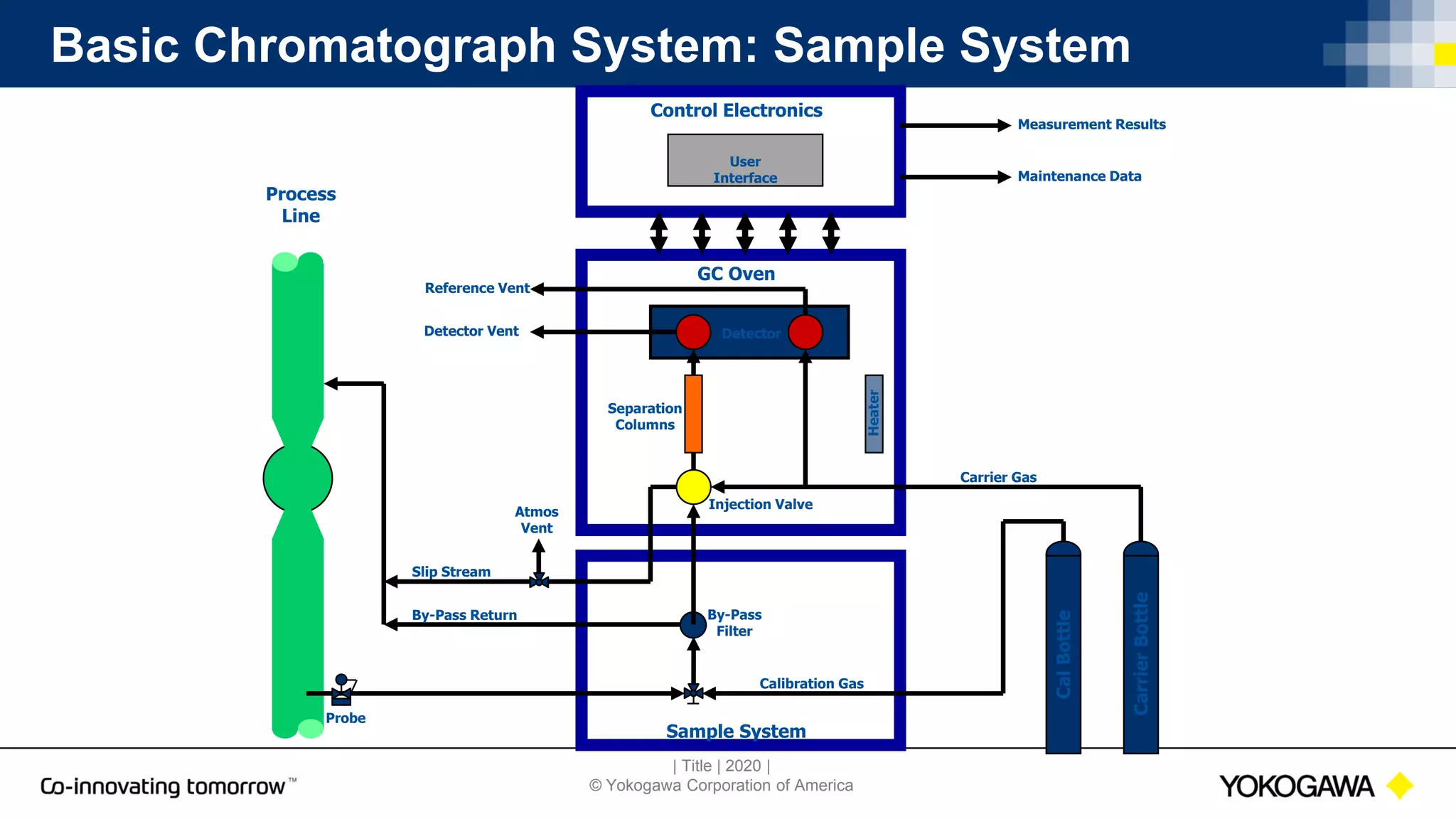

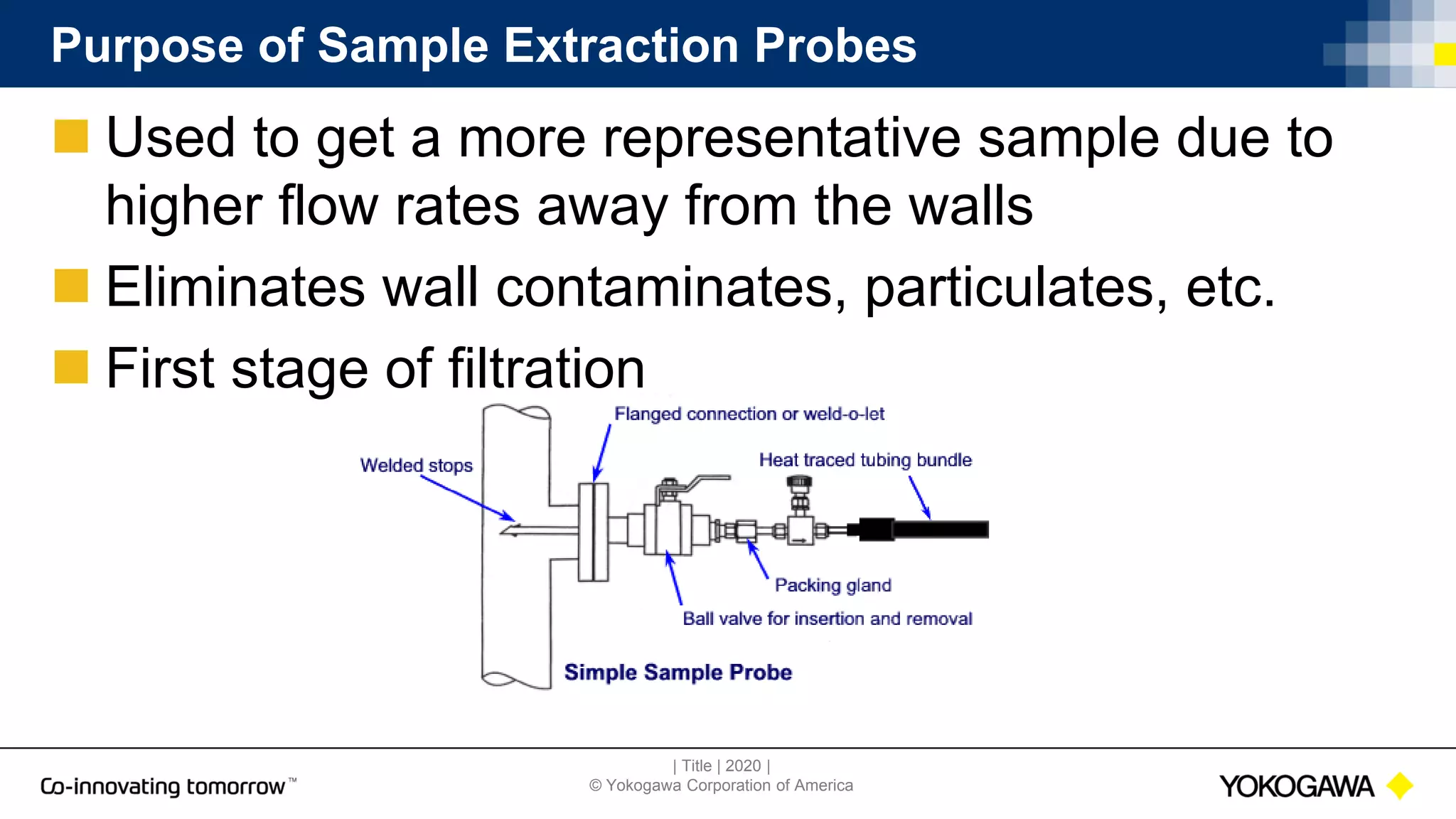

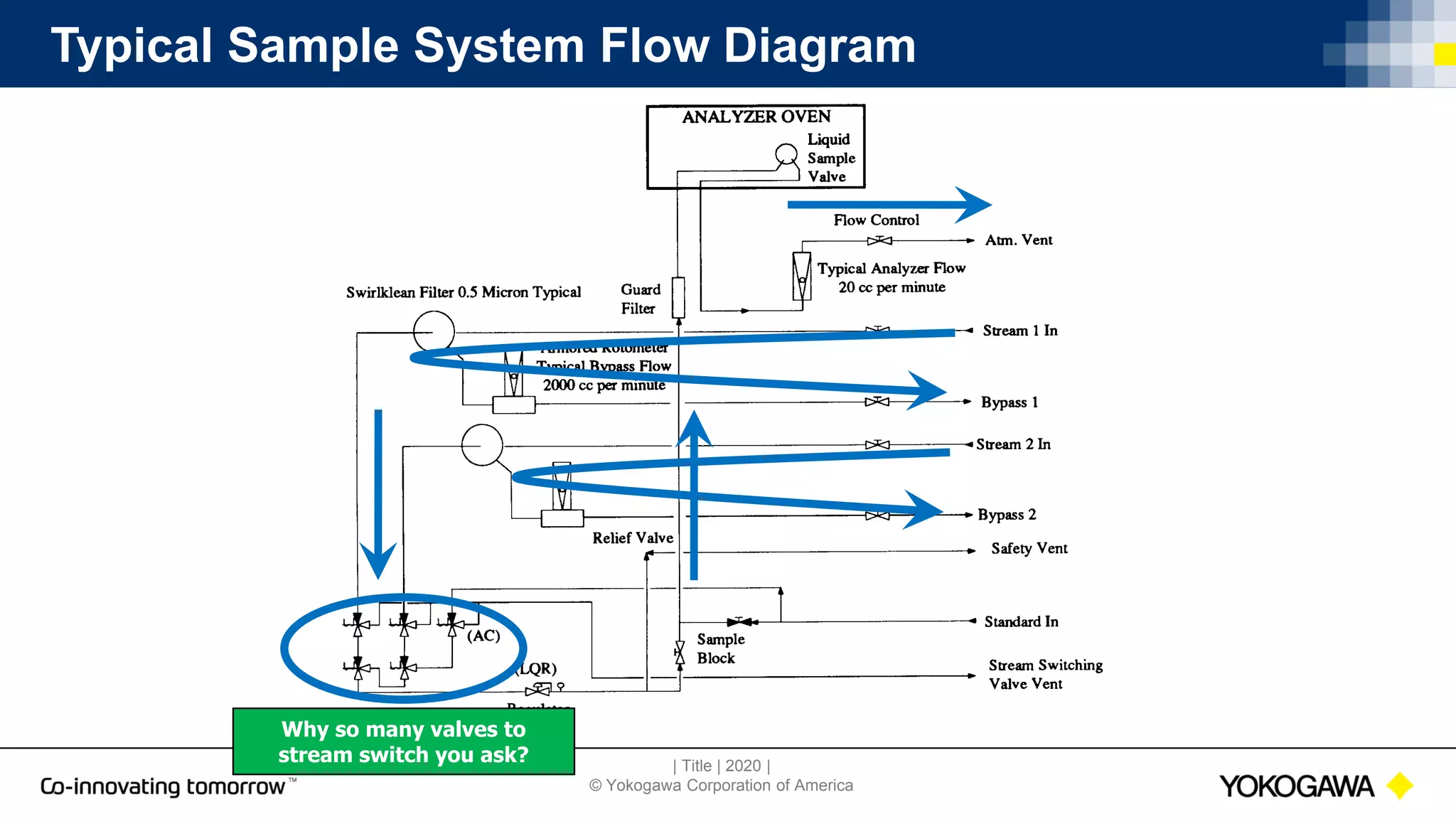

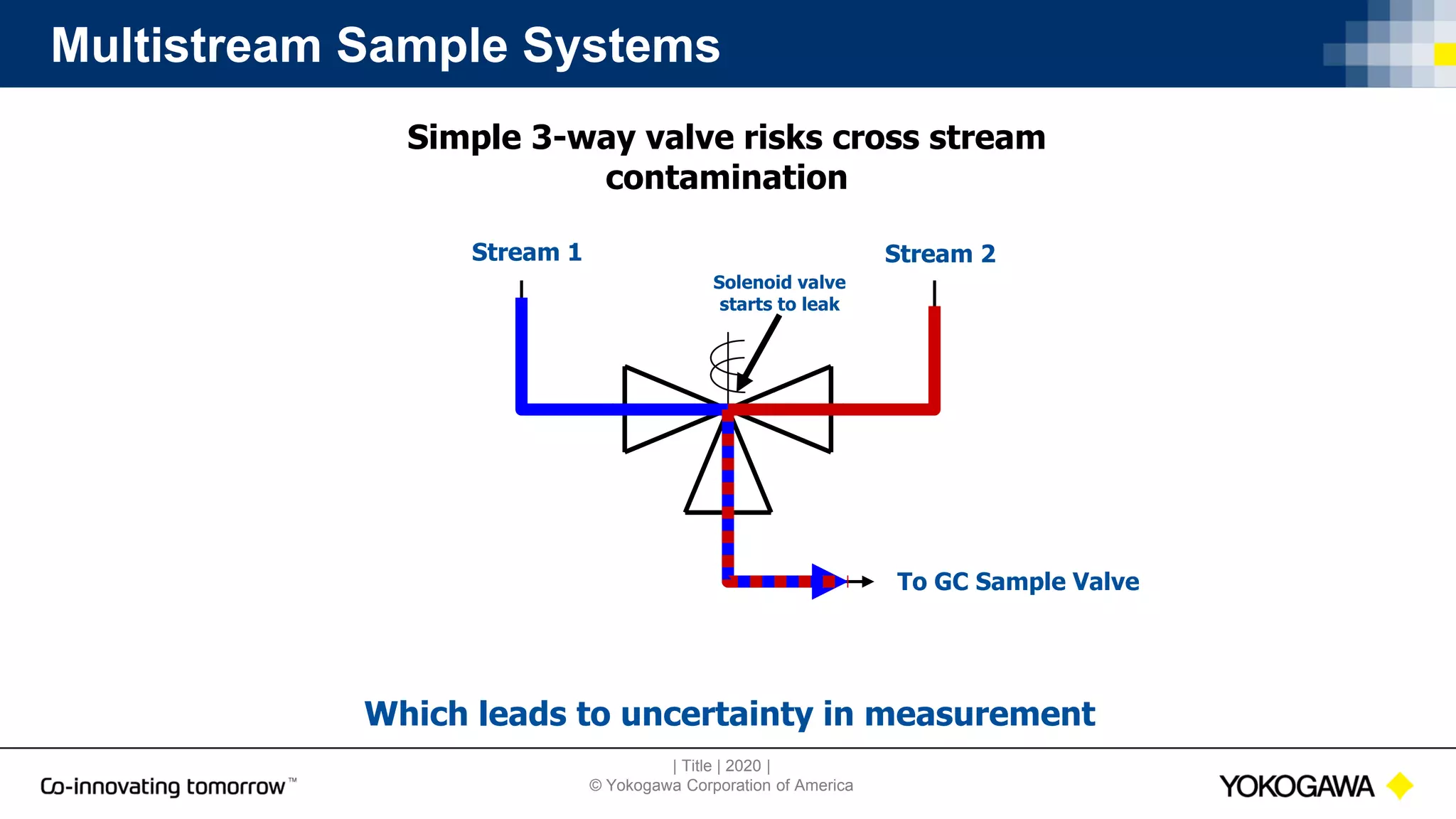

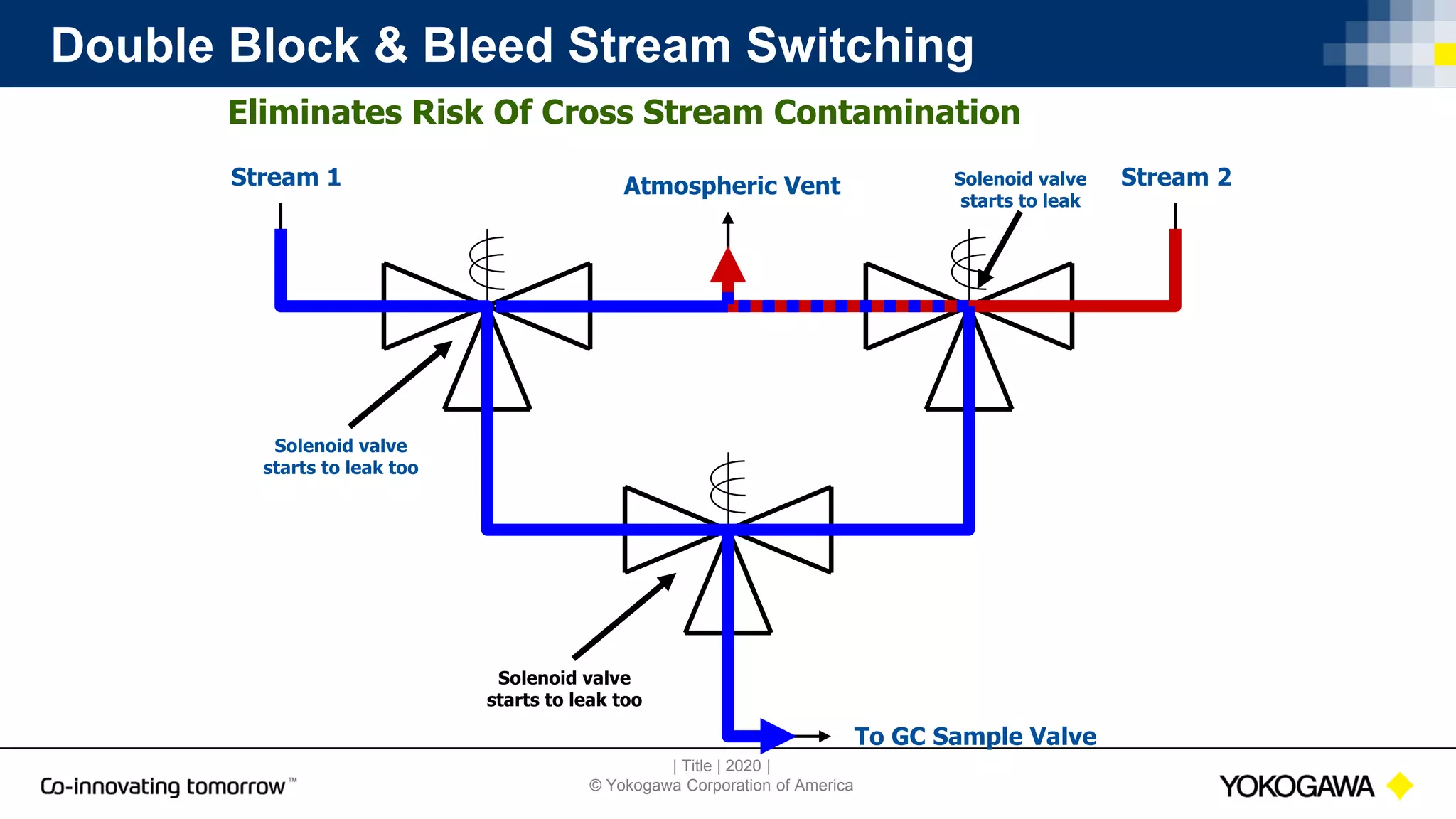

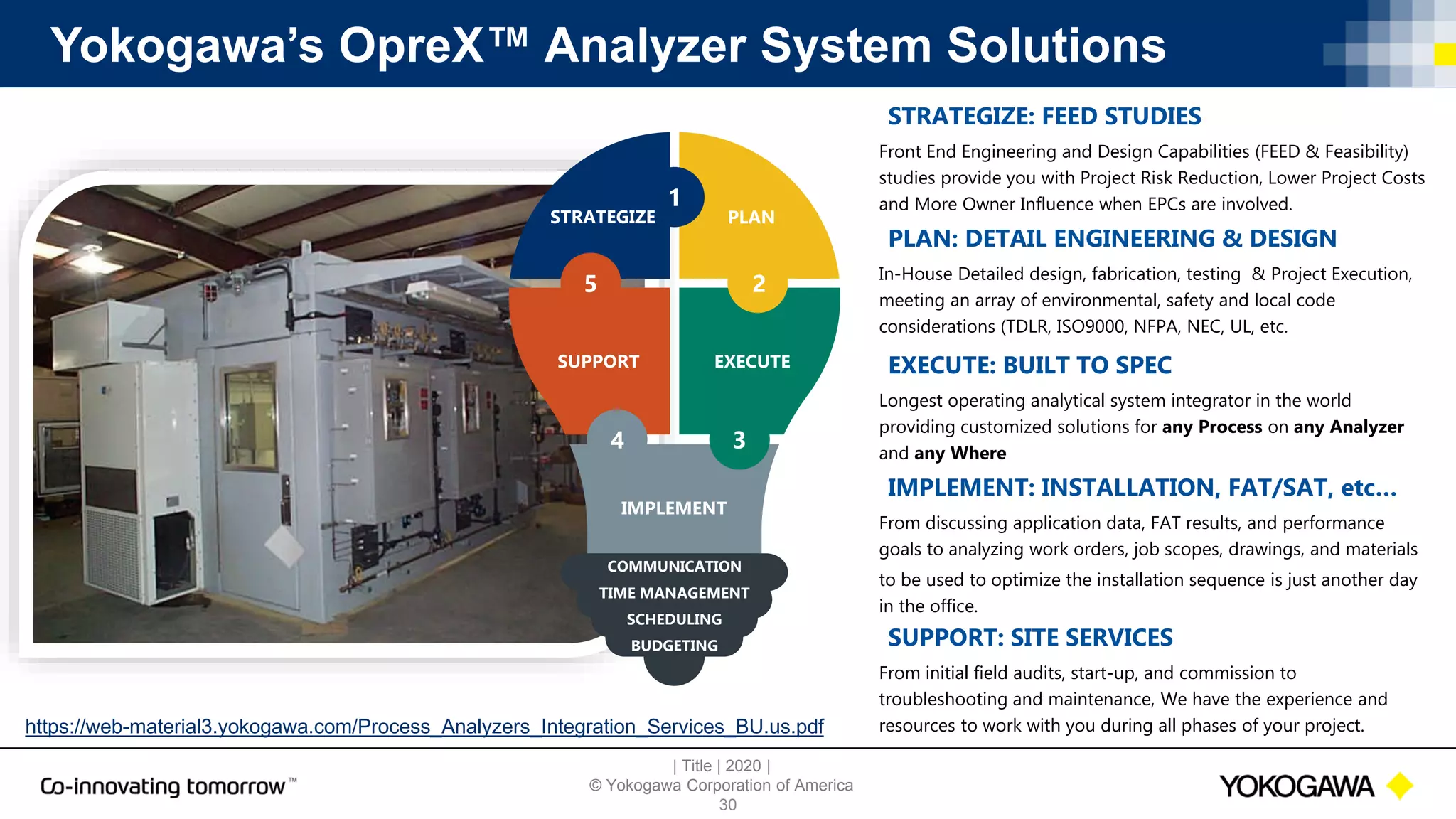

The document outlines a webinar on gas chromatography, highlighting the expertise of the presenters Tim Roth and Scott Eddleman. It covers fundamental principles of gas chromatography, various components such as sample injection valves, separation columns, and detectors, as well as techniques for analysis and sample conditioning. Additionally, it details the importance of sample extraction, system design, and the offerings of Yokogawa in analytical solutions.