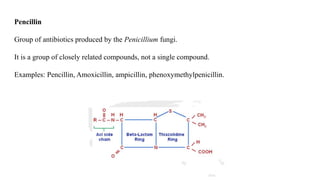

This document summarizes the industrial production of penicillin using Penicillium chrysogenum. It discusses that penicillin is produced by fermenting Penicillium fungi in a controlled, homogeneous environment. Bubble columns are commonly used as the fermentation reactor since they can efficiently mix and oxygenate the high viscosity broth. The optimum conditions for growth include a pH of 6.5, temperature of 20-24°C, sufficient oxygen supply, and a specific nutrient media formulation. After 7 days, growth is completed and penicillin production ceases, at which point filtration and solvent extraction are used to isolate the penicillin-sodium salt product.