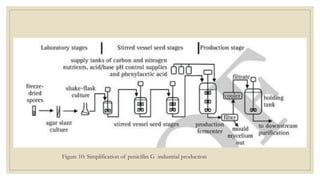

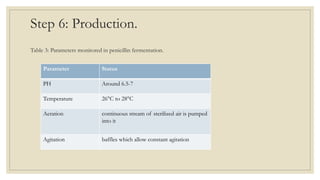

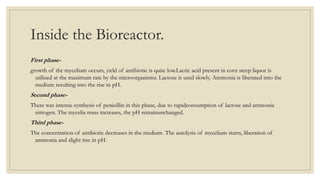

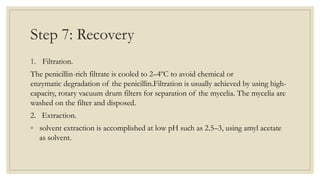

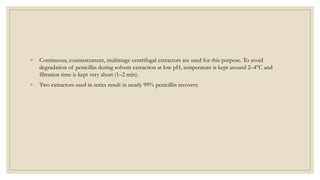

The document provides an in-depth overview of antibiotics, particularly penicillin, including its definition, discovery, structure, production process, and fermentation stages. It discusses the types of penicillin and the microorganisms involved, emphasizing the importance of maintaining pure cultures and optimizing conditions for maximum yield. The document covers the entire production process from inoculum preparation to purification, highlighting key parameters and challenges in penicillin fermentation.

![Antibiotics

◦ The term antibiotic has been defined by Selman Waksman as being an

organic compound produced by one microorganism that inhibits the growth

of or kills a group of harmful microorganisms (Bacteria).

◦ These enter and stick to important parts (think of targets) of the bacterial cell,

and interfere with its ability to survive and multiply [1].

If the bacteria are susceptible to the antibiotic, then they will stop growing or

simply die.

◦ These important parts include:

◦ Proteins/sugars in the bacterial wall.

◦ Important enzymes that make new bacterial DNA or proteins[2].](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-2-320.jpg)

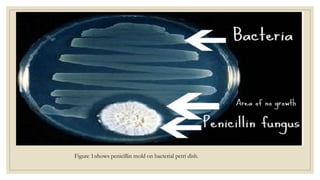

![First Naturally-occuring Antibiotic

◦ Fleming was already well known upon

his return from a long holiday in September

1928, he noted that one petri dish contained

colonies of staphylococcus bacteria except for

clear area contaminated with a fungus that

appeared to inhibit bacterial growth. The

mold was found to be penicillium notatum[3].](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-4-320.jpg)

![Staphylococcus Aureus

◦ Staphylococcus is a genus of Gram-positive bacteria. Under the microscope, they

appear spherical, and form in grape-like clusters. It can cause scarlet fever, pneumonia

or sepsis [3].

Figure 2: illustrations of staphylococci bacteria and its arrangement.](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-6-320.jpg)

![General Structure

of Penicillin

Penicillin is not a single compound but a

group of closely related compounds, all

with the same basic ring-like structure (a

β-lactam) derived from two amino acids

(valine and cysteine) via a tripeptide

intermediate.

The third amino acid of this tripeptide is

replaced by an acyl group (R) and the

nature of this acyl group produces

specific properties on different types of

penicillin.[4].

Figure 3: Shows the chemical Structure of Penicillins

group.](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-7-320.jpg)

![Figure 4: Pathway of penicillin G by Penicillium Chrysogenum[4].](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-8-320.jpg)

![Step 1: Inoculum Preparation.

◦ Inoculum: A small amount of material containing bacteria, viruses,

or other microorganisms that is used to start a culture[5].

◦ Out of various species of the fungus Penicillium, mainly two species are used in

the fermentation:

◦ These are P. notatum & P. chrysogenum but P. chrysogenum is high yielding

strain and therefore most widely used as production strain[6].](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-11-320.jpg)

![Myceilium

◦ The mycelium is well developed and

copiously branched.

◦ It is composed of colourless, slender,

tubular, branched and septate hyphae.

◦ The hyphae run in all directions and

become intertwined with one another

to form a loose network of hyphae

constituting the mycelium.

◦ Myceilium is the vegitative part of

the mold [7].

Figure 5: Shows the Mycelium structure and how

spores germinate.](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-13-320.jpg)

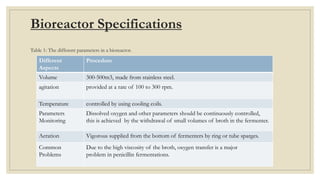

![Step 5: Bioreactor Set-up.

Fed-Batch culture: to feed a batch by controlled addition of a carbon source

and/or other nutrients, resulting in a fed-batch culture.

Air-lift Bioreactor:

◦ Advantages:

considerably higher volumetric and specific productivities since the phenotype

of the cell is under better control[8].](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-20-320.jpg)

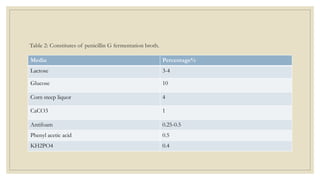

![Nitrogen Source:

◦ Another essential compound for metabolism of organisms is nitrogen.

◦ We use Corn steep liquor (CSL), since it results in higher penicillin yields as

compared to the other nitrogen sources. Some compounds in CSL are

converted to phenylacetic acid or other side-chain precursors.

◦ Cottonseed flour or soybean meal may also be used as nitrogen sources; however,

they are more expensive than CSL [9].](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-24-320.jpg)

![Ammonium Source.

◦ Continuous addition of ammonium sulfate to keep the ammonium concentration

around 250–300 mg/L is required for continued synthesis of penicillin and

to avoid lysis of the mycelium.

◦ The omission of ammonium nitrate decreased the penicillin activity in the

original fermentation medium (Table I).

◦ This result agrees with the findings of [10] they reported that ammonium

nitrogen is a limiting factor in penicillin production.](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-25-320.jpg)

![Mineral Source:

◦Additionally, some minerals are necessary for the proper growth of these

organisms. are included.

◦ These elements include phosphorus, sulfur, magnesium, zinc, iron, and copper

which generally added in the form of water soluble salts.

◦For example:

◦However, the pH at the end of the fermentation period is slightly lower, when

low concentrations of calcium carbonate were used[10]](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-26-320.jpg)

![AntiFoam Agents:

Anti-foaming agents such as lard oil to reduce foam formation.

Disadvantages of Foaming:

1. Reduce process productivity since bursting bubbles can damage proteins[11],

2. Can result in loss of sterility if the foam escapes the bioreactor[13].

3. leads to over-pressure if a foam-out blocks an exit filter.](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-27-320.jpg)

![Precursors.

◦ Certain precursors of the penicillin side chain need to be added into the

fermentation medium.

◦ This constitutes a major cost item. Penicillin G requires 0.47g sodium phenylacetate.

◦ the precursor must be added repeatedly in small amounts during the fermentation:

why?

In order to avoid toxic effects.

◦ The Phenylacetic acid appears to be the best precursor, but it can be substituted or

replaced by other ring systems[14]. it is transported across the plasma membrane by

free diffusion into myceilium.](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-28-320.jpg)

![Final product.

◦ Benzylpenicillin (Penicillin G)[15].

Figure 8: Biosynthesis of 6(APA) to Penicillin g.](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-32-320.jpg)

![Kinetic Models

◦ The original model has been extended by including additional input variables such as agitation power and

aeration rate [12].](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-33-320.jpg)

![Initial conditions and kinetic parameters.

Table 4:Original fermentation Kinetic model and its initial conditions [12].](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-34-320.jpg)

![Figure 9: Glucose and penicillin concentrations at initial glucose concentrations of 15, 25, 30 g/l [12].](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-35-320.jpg)

![Figure 9: Main Bioreactor Configuration [16].](https://image.slidesharecdn.com/penicillinkd-240831021933-57820c6a/85/Penicillin-structure-and-its-uses-kd-pdf-40-320.jpg)