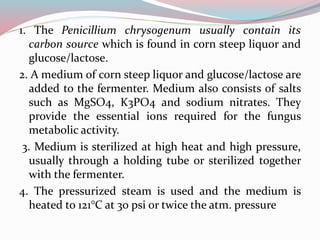

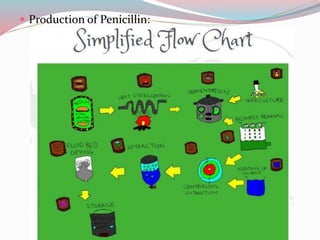

Penicillin is produced through the fermentation of Penicillium fungi. The production process involves growing the fungi in a liquid culture medium under controlled conditions. As the fungi grows, it produces penicillin. The fermentation broth is then filtered to remove the fungi biomass. Organic solvent extraction is used to extract the penicillin from the broth. Finally, the penicillin is purified into a powder through further extraction, crystallization, and drying processes.

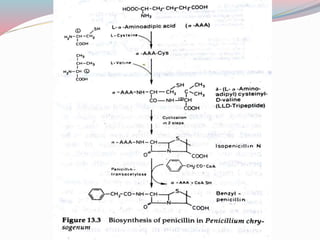

![Biosynthesis

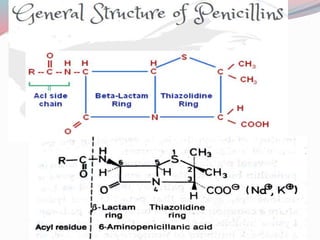

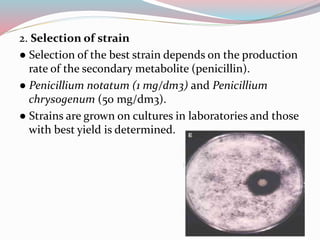

β-Lactam – thioazolidine ring is made from L-Cysteine

and L-Valine. It is a non-ribosomal process occurs by

means of dipeptide composed of L-α-aminoadipic acid

(L -α -AAA) and L-Cysteine.

Subsequently L-Valine is connected via an epimerization

reaction, resulting in formation of tri-peptide [δ-(L-α-

aminoadipyl)-cysteinyl-D-valine] LLD-tripeptide.

Benzyl penicillin is produced in exchange of L -α –AAA

with activated phenylacetic acid.

6-APA is excreted in absence of side chain precursor

instead of benzyl penicillin.

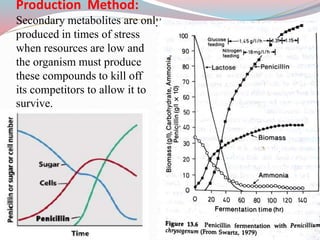

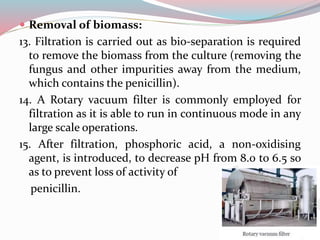

Penicillin biosynthesis is affected by phosphate conc. and

also show catabolite repression by glucose, so many a time

performed with slow metabolizing sugar lactose.](https://image.slidesharecdn.com/penicillinfermentation1-200301052316/85/Penicillin-fermentation-1-12-320.jpg)

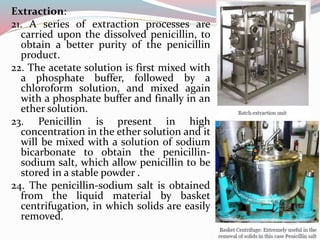

![Penicillin fermentation[1]](https://image.slidesharecdn.com/penicillinfermentation1-200301052316/85/Penicillin-fermentation-1-34-320.jpg)