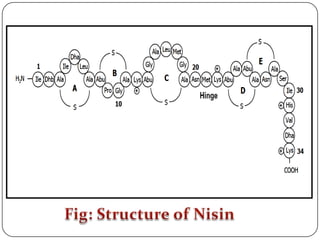

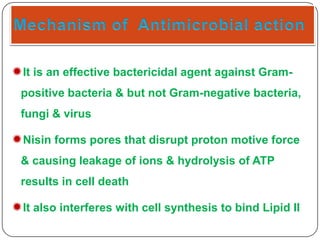

Biotechnology refers to the use of living organisms to develop products. Nisin is a bacteriocin discovered in 1928 that is produced by Lactococcus lactis bacteria and is effective against gram-positive bacteria. It has a variety of applications including use as a food preservative and therapeutic agent. Nisin is produced through fermentation and purified using various methods before being approved for use in processed foods and to preserve dairy products.